In the industrial field, the additive manufacturing of plastic functional components has high requirements. In addition to high quality and high strength, the processing range of raw materials must also be wide, and the equipment therefore also needs to have flexible adjustability. Today, a hybrid machine that combines machine tool technology with 3D printing, the screw extrusion additive manufacturing system, is being valued by the Fraunhofer Association and Arburg . The former is a well-known R & D institution for 3D printing technology. The other is the world's leading manufacturer of plastic processing injection molding machines, so we can see the application potential of this technology. In this issue, we take the Arburg printer as an example to introduce this plastic 3D printing process that is different from FDM.

Different from FDM plastic screw extrusion additive manufacturing system

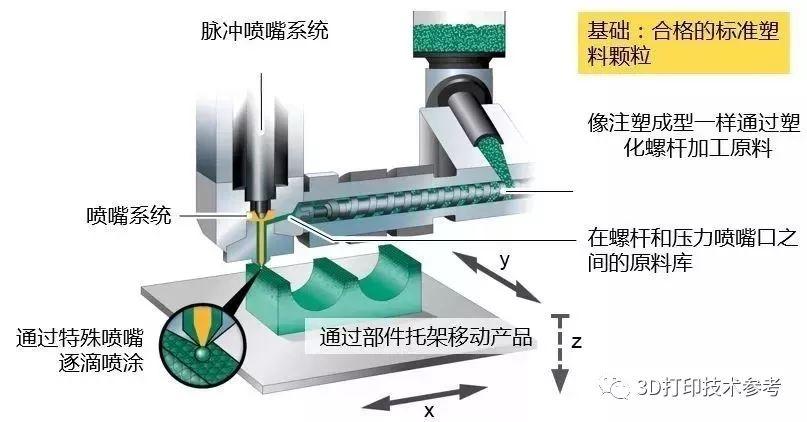

A huge advantage of the screw extrusion process is that it can directly process low-cost qualified standard particles for injection molding. The printer integrates the material preparation function through a special screw. After the material is melted, plastic droplets are ejected through the nozzle switch pressed by high-frequency piezoelectric technology, and these droplets are accurately and flexibly positioned with the support of the control mechanism.

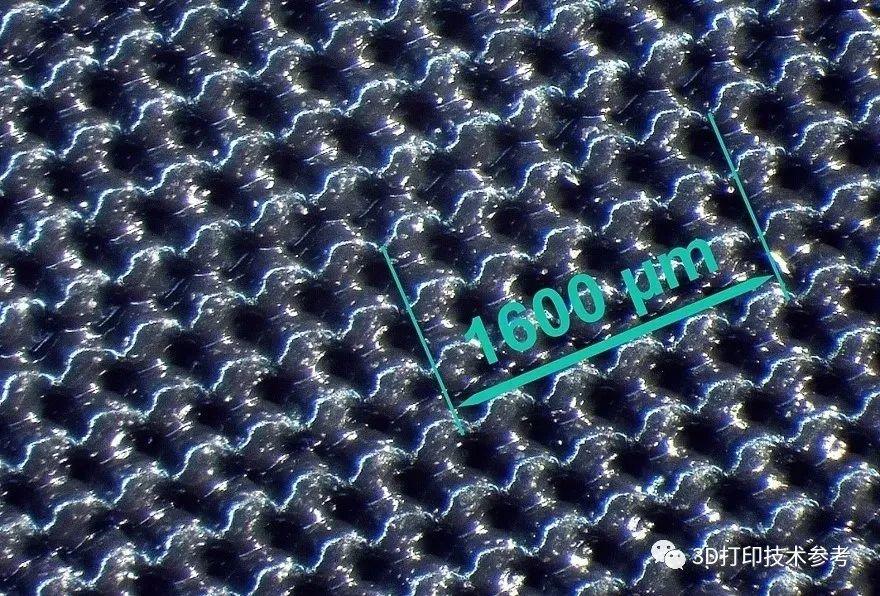

Compared with the injection mold, the Arburg screw extrusion process achieves high-precision manufacturing of products by controlling the droplet size and process . The printer is equipped with nozzles of different sizes with diameters of 0.15, 0.2 and 0.25 mm respectively. The ejected droplets are not circular, and their shape is mainly determined by the viscosity of the material. This point needs to be noted when constructing the thickness: the droplet height determines the layer thickness-varying between 0.14-0.34 mm.

Feeding frequency from 100-200 drops / second, up to 200 drops / second; material pressure is 150-500bar

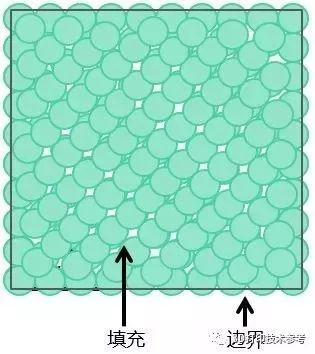

In order to determine the total amount of droplets, the shape factor also needs to be considered, which reflects the width-to-height ratio of non-precise circular droplets . The layer thickness and shape factor are related to each other, which needs to be taken into account when performing mathematical algorithms on slices and when designing machine-specific NC programs. For example, doubling the shape factor will cause a droplet to occupy four times its space.

Adjustable parameters include: number of boundary lines, degree of boundary coincidence, starting angle, increasing angle, filling density, aspect ratio of gob, etc.

By grasping the relationship, you can use structural properties purposefully. The denser the droplets, the thicker the component is "packaged" and the stronger its mechanical properties. Therefore, when the correlation between the thickness of the injection molded part and the material reaches 95%, the tensile strength will reach 97% (the tensile test is performed according to DINEN ISO527-02). The smaller the layer thickness, the smoother the surface of the structure; the larger the layer thickness, the shorter the construction time.

Simultaneous processing of multiple raw materials, water-soluble support

Individually optimized components, multi-functional and multi-component products

Compared with other production processes, the screw extrusion process can personally optimize the quality and stability of 3D printed components. This is related to various production materials, but the prerequisite is to have an " open production system ". The Arburg 3D printing system can not only adjust all process parameters such as layer thickness, temperature and droplet position, but also its special special screw structure can complete the material preparation function, so that it can produce multi-functional and multi-component products .

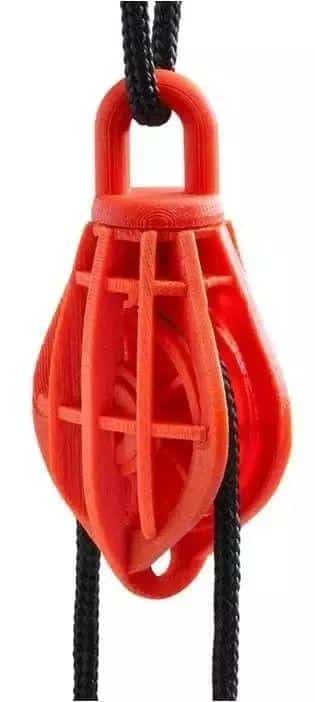

Gripper

Materials: ABS, TPU and armat 21

Layer thickness: 0.2 mm

Construction time: about 16 hours

Features: Mobile functional parts similar to human finger touch, made of hard / soft rubber

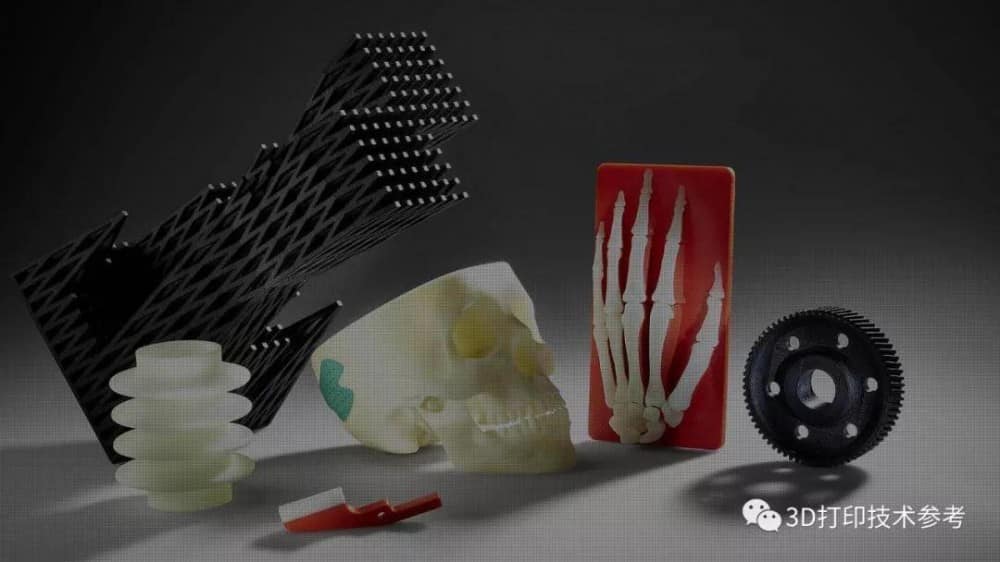

In order to improve material quality and achieve optimized process settings, structural construction methods must be considered under a highly free choice. At present, the material library suitable for the screw extrusion process is constantly expanding, and there are corresponding process settings for different thermoplastic materials. Not only can the additive standard materials ABS, PC, PA12 (amorphous), but also semi-crystalline PP and special plastics, such as high-temperature materials PEI, elastic TPU or biopolymer materials .

Material: Biopolyamide

Layer thickness: 0.27 mm

Construction time: about 22 hours

Features: Flexible load-bearing functional parts including housing and fixing hook

An important feature of Arburg 3D printing is that, like the injection molding process, it can process low-cost qualified standard particles, which has a lower material cost compared to traditional FDM wire . Direct use of raw materials can efficiently produce single or small batch parts and functional parts, and can also produce large batch products personally.

PC for aviation and absorbable PLA for medical technology, also can be made of transparent materials

Applications of screw extrusion additive manufacturing system

In the development process of plastic products, it is usually necessary to obtain the prototype of the product according to the design CAD model of the plastic product. If the user is satisfied with the prototype, then it will enter the mass production stage. If the batch size is not large, Then, it is often more economical to realize by 3D printing than the traditional way of opening the mold ; and it is obvious that in small batch manufacturing, the screw extrusion process is also more industrially meaningful than the traditional FDM.

Based on this, Arburg hopes to develop a small batch production additive manufacturing equipment that can replace the classic large-scale plastic injection molding. From the professional experience in the field of plastic injection molding and machinery manufacturing, Arburg uses the principle similar to that of injection molding machines to implement printing, and the materials used are also consistent with the pellets of the injection production line, which makes the different production technologies The span of a supply chain that is too large needs to be adjusted .

In addition, compared with FDM technology, the products manufactured by Arburg screw extrusion process have better quality, and their products have also been applied in aerospace, automotive, medical and consumer products industries.

END

Examining additive manufacturing from the perspective of injection molding has produced this kind of plastic molding process that breaks through traditional FDM. Its outstanding features include low material prices and wide applicability of equipment, and even outstanding performance in terms of functionality.

In addition to Arburg, the Fraunhofer Machine Tool and Forming Institute in Germany announced on March 15 that it has successfully developed a similar process, which is 8 times faster than traditional 3D printers and uses low-cost raw materials.

The breakthroughs in speed, cost, functionality and equipment applicability of the plastic pellet screw extrusion process have undoubtedly paved the way for the industrial production of plastic 3D printing.