Increasingly, a number of large, mainstream corporations, like HP and Microsoft, are entering the 3D printing space, potentially overshadowing mainstay industry players and small startups with their huge market caps and histories of technological innovation. One of the most interesting companies in the 3D printing industry, however, is a somewhat smaller business that has only recently begun to make its presence known outside of the French market. After today, not only will the presence of Groupe Gorgé and its 3D printing subsidiary, Prodways, be known outside of France, but they will be impossible to forget because, at Euromold, Prodways has announced a deal with Farsoon, the world’s third-largest manufacturer of selective laser sintering 3D printers, laying the foundation for a truly powerful business in the 3D printing industry.

The deal will see a strategic partnership between Prodways and the Chinese company to develop a full range of laser sintering machines for both plastics and metals. Based on Farsoon’s current range of SLS 3D printers, the new line will be branded as the “Prodways powered by Farsoon” line, assembled at the Prodways site in Les Mureaux, and marketed by Prodways worldwide in the coming months. Not only does this partnership expand Prodways’ material and process capacities beyond the company’s own MOVINGLight® technology and resins, but it may very well disrupt the 3D printing market altogether. To learn more about the news, I was able to speak to CEO of Groupe Gorgé, Raphaël Gorgé, whose thoughtful strategy towards the industry seemed to affirm my suspicions that Prodways would become one of the most important companies in 3D printing in the near future.

Prodways was fist established as Phidias Technologies by inventor André-Luc Allanic, who was able to combine LED technology with Digital Light Processing (DLP) to create a scalable process capable of 3D printing large, high-resolution objects. After its acquisition by the $305 million, publicly-traded Groupe Gorgé (EPA: GOE) in 2013, Prodways has grown significantly, bringing both its MOVINGlight technology and the subsidiary itself into the 3D printing spotlight. CEO Gorgé says, “As you know, we started Prodways roughly two years ago and, during the first two years, we developed a range of DLP machines using MOVINGLight technology. We came to the conclusion that those projects dedicated to 3D printing, for manufacturing, were well-designed and, more than that, we came to the conclusion that Groupe Gorgé was ready to be more ambitious in the development of 3D printing.”

The group’s ambition has so far paid off. In the past year alone, the revenue from the 3D printing division of Groupe Gorgé grew by 700%, a feat that was accomplished through keen strategy that first focused on Prodways’ own technology, before expanding onto other 3D printing materials and processes. “The 3D printing market is very interesting because you have two world leaders, 3D Systems and Stratasys, which are offering almost all of the technologies, services, and materials,” Gorgé explains. “And, after those, two significant leaders, there are, I would say, a dozen players that specialize in only one specific technology. Prodways was one of them, but we thought that we had the capacity to develop our sales faster, due to the fact that we can rely on the financial resources, but also the management team and, more generally, the expertise of Groupe Gorgé, which would enable Prodways to grow faster.”

For that reason, the industry saw Prodways, first, release nine different 3D printers and fourteen materials at Euromold last year. This was followed by the acquisition of Norge Systems, a UK startup that had created an entry level selective laser sintering system, making Prodways more than the inventor of a single technology, but a multi-technology firm. “So, basically, the idea was to try to accelerate and widen the portfolio of technology,” the CEO says. “Because we want to become the third player in the world to offer a multi-technology 3D printing portfolio for manufacturing. And, this is the new strategy that we started six months ago. This is why we raised €25 million, three or four months ago, and also, we started to acquire and target new technologies. We made the acquisition of Norge, a startup involved in SLS for plastic powder.”

New acquisitions were just the beginning for Prodways, however. To augment the entry-level line of the Norge machines, and its plastic powders, Grouope Gorgé looked towards Farsoon. “It was a first step, but we were also discussing other options because, obviously, we are very interested in plastic laser sintering, but, also, in metal. There are, as you know, very few companies in the world that are involved in metal laser sintering, or DMLS.”

“[The] development [of Farsoon] has been very similar to the development of Prodways,” Gorgé says, “Very fast, with significant resources – financial and technical – and they succeeded in developing, in 5 or 6 years, a very interesting range of machines. So, we decided to join our efforts with Farsoon to be able to strengthen their range, their machines, and sell them by developing a new range branded as ‘Prodways powered by Farsoon’. And we would be able to sell this new range of plastic SLS and DMLS all over the world. Basically, this is the idea of the deal and this I think helps us make a significant step forward in order to become, I would say, one reliable, solid alternative to the two big US players.”

While Prodways will benefit from the expanded technology and materials portfolio, Farsoon has access to Groupe Gorgé’s presence in almost every continent. Last year, this global network sent Prodways across Europe, before carrying the subsidiary to the US and, most recently, into Hungary and Israel. Dr. Xu highlighted the benefits this brings to Farsoon in today’s announcement at Euromold, “I am delighted by this partnership with Prodways, which boasts a well-known brand and has a very extensive network of dealers and service providers, and allows innovative solutions based on our technologies to be proposed to industrial customers worldwide.”

The Prodways by Farsoon range and the systems developed by Norge will be able to complement one another. With its own resources, Groupe Gorgé will be able to modify the Norge systems to produce a quality, entry-level platform, which will give the company a broader range of SLS printers when augmented with the Farsoon line. While Mr. Gorgé explains that the Norge systems – which prior to acquisition, consisted of a larger Ice 9 and a smaller Ice 1 machine – won’t be at the same level as the Prodway by Farsoon systems, they will be primed for those that don’t have the same budget as big businesses. The CEO tells me, “Because, in the end, we want to target all of the needs in the world of 3D printing. Some are interested in high-end machines that cost many of hundreds of thousands of dollars. Others might be interested by a little bit less expensive system – even if they are a little bit simpler.”

“As you know, in SLS, the material is very strategic because one important of future growth will definitely be in the capacity to develop new materials.” Gorgé continues, “On one hand, we can secure access to material with our own manufacturing capacity, which belongs to Farsoon. And, on the other hand, we can improve on the material and partner with Farsoon on the development of new powders, which I think is very important for the future.”

As access to materials remains key in this growing industry, so, too, is service, Mr. Gorgé says. Not just in producing parts, but in customer service and the maintenance of machines. In Minnesota, Prodways opened its first North American subsidiary, where it is able to provide support to customers in the US. With the new Farsoon partnership, though, the company is able to leverage Farsoon’s Texas hub, Varia 3D, of which Prodways now owns a 45% stake, subject to increase in the future. The Varia 3D service bureau can provide SLS 3D printing, as well as machine maintenance and technical upgrades thanks to the expertise of its founders, Brian Bauman and Chuck Kennedy, who, like Farsoon’s Dr. Xu, were a part of DTM Corporation’s early team.

Interestingly, Dr. Xu wasn’t just acquainted with Bauman and Kennedy before Farsoon tapped them as a North American distributor last summer, but he has been acquainted with Prodways founder Dr. André-Luc Allanic since the two of them worked at 3D Systems. Philippe Laude, Deputy Managing Director of Prodways Group, says in today’s press release, “Farsoon and Prodways share the same vision and the same values of innovation and a constant search for the best solutions for their industrial customers. Moreover, Dr. Xu and Dr. Allanic have already worked together at 3D Systems before founding their own companies and developing groundbreaking 3D printing solutions.”

While Dr. Xu went on to cultivate his SLS technology, Dr. Allanic’s MOVINGLight technology has been a standout for its novel DLP approach. With Prodways’ ProMaker L8000, for instance, capable of fabricating parts with a diagonal length of over 1 meter and up to 550 mm tall, MOVINGLight is remarkable in the industry in its ability to produce large-scale, high-resolution parts in a wide variety of materials very quickly, but 3D printing technology is still relatively new, particularly when it comes to quality control and reliability. As big and detailed as these prints might be, Mr. Gorgé touts the repeatability of Prodways’ 3D printing technology whether printing objects large or small, particularly because the large build volume of the machines could be used for mass production. “You can also print many identical parts on the same production. For an aircraft engine, it might not be necessary to print very large parts, but relatively small objects at a very reliable definition and quality with each production and each batch, from one production to another and one day to another.”

Gorgé points out that, in Groupe Gorgé, the company deals with critical applications, such as nuclear safety equipment, and, in that field, the equipment is supposed to work for 60 years. As a result, the company has focuses very heavily on reliability. “What we’re used to delivering in the Groupe Gorgé, we are used to working in very demanding industries: aeronautics, nuclear… We are targeting the reliability of the industrial process, which is a must when dealing with industrial applications.”

He’s quick to remind me that, in an industrial application, reliability is always critical to the customer, whether it be aerospace or jewelry manufacturing. “Even if the application may not seem critical to someone else, for [the customer], having a machine that is running smoothly twenty-four hours a day is critical.”

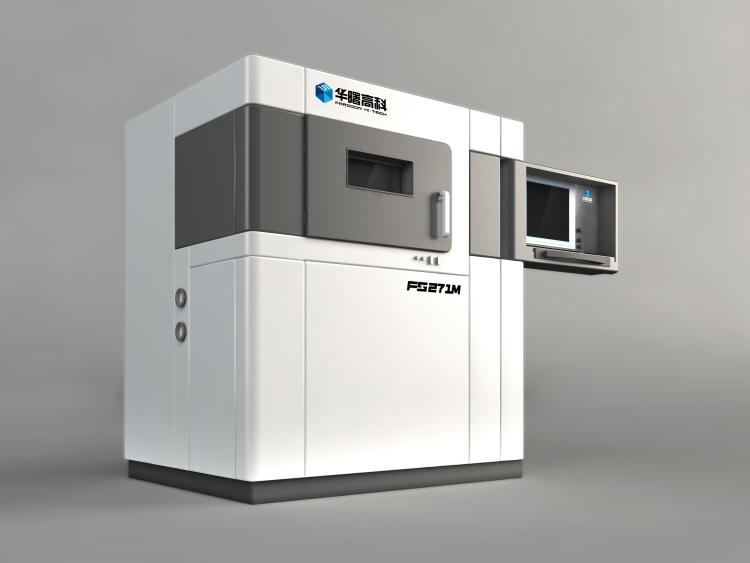

At the moment, Mr. Gorgé wasn’t able to speak to the exact specifications of the upcoming range of SLS 3D printers being developed as a result of the collaboration, or the materials that will be manufactured for them, but the details, he says, will be made public by the end of the year. In the meant time, some guesses can be made based on Farsoon’s current offering, which includes the FS271M machine, a metal sintering machine with a build volume of 275 x 275 x 320mm (10.83″ x 10.83″ x 12.6″) and a 500W ytterbium fiber laser for sintering stainless steel and chrome. The smaller Farsoon 251P and larger FS402P series are available in different speeds with more or less powerful lasers capable of sintering nylon and nylon composites, including carbon fiber and glass bead-filled nylons.

The Chinese media reports, however, that Farsoon’s Dr. Xu isn’t only working on SLS, but has revealed some details regarding a new type of stereolithography technology that can 3D print with more quickly and with more viscous materials than traditional SLA. Though there are no plans to embark on this venture at the moment, Mr. Gorgé assures me that, if their initial partnership is successful, there’s no reason for Farsoon and Prodways to collaborate on new technology and materials R&D in the future. In the meantime, I have no doubt that this partnership will be a powerful one, leveraging experts from two disparate 3D printing technologies, along with the financial and business acumen of Raphaël Gorgé, to present what could be a third global player in 3D printing. More than HP, with its Multi Jet Fusion, I believe that the 3D printing leaders of yesterday are scared of the 3D printing leader of tomorrow, manifested in Prodways powered by Farsoon.

Leave A Comment