Canada’s additive manufacturing accelerator program Canada Makes, headquartered in Ottawa, has invested $750K in a facility for micro metal component manufacturers Shimifrez Inc.

The money will be used to help fund production of incredibly thin copper parts used as a electrical conductors in micromachines. Having applications in a range of industries, like aerospace, automotive and medical, these micromachines control the mechanical reaction of things like impact airbags.

Clip from an air bag Toyota crash test, via ToyotaSubaruCrashTests on YouTube

Micro additive technique

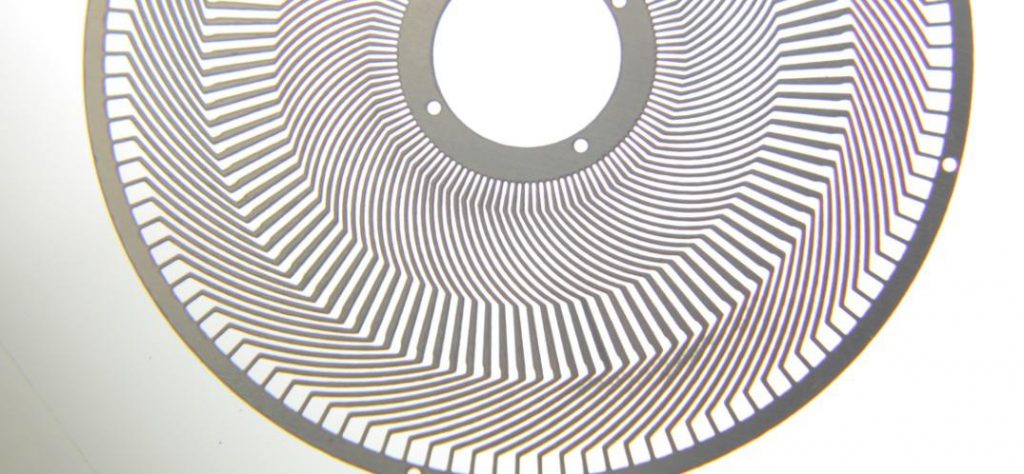

Operating on the micron level of additive manufacturing, Shimifrez use a process of electro forming to make thin chips of metal. The basis of the method is as follows;

- A plate of metal, typically nickel, and a mandrel or “master surface” are placed in an electrolytic bath.

- The electrolytic charge causes nickel particles to create layers on the master surface.

- Once the desired thickness is achieved, the nickel can the then be extracted from the mandrel, leaving a part that is a negative image of its surface.

Being directly extracted from a surface in this way means that the parts have 1:1 accuracy. The method can be used either to make simple shapes, or more complex patterns.

More jobs in Ontario

The investment in Shimifrez is part of Canada Makes’ Metal Additive Demonstration Program; “designed to help Canadian industries increase awareness and assist in understanding the advantages of the metal additive manufacturing (AM) technology”. Initiative partners include Canadian branches of Renishaw and EOS. The product of one of the company’s partnerships also helped send a 3D printed satellite part into space.

Photo electro forming of copper parts is performed at Shimifrez’s site in Vaughan, Ontario. The Metal Additive Demonstration Program investment will expand this site and create 8 new jobs.Hassan Nojoumi, President of Shimifrez Inc., comments,

Canada Makes assistance helped Shimifrez take a big step in developing our capabilities to deliver rapid-response service for micro components to several precision industries such as the aerospace/satellite, medical, automotive, telecommunications and micro- electronics sectors.

To stay up to date with the latest news on metal additive manufacturing on a micro and a macro scale sign up to the Industry newsletter, and follow our active social media channels.

Readers can now vote in the first annual Industry Awards.

Featured image shows an electroformed disc with leaf-like design, made with micro level additive manufacturing. Photo via Shimifrez

Leave A Comment