3D printing is reshaping the way motorcycle enthusiasts, designers, and manufacturers approach both prototyping and customization. From finely detailed scale models to practical aftermarket components, the technology bridges the gap between creativity and engineering.

Scale Models and Collectibles

3D printing brings motorcycle icons to your desktop. Whether it’s a 1:12 Honda CC110 or a 1:64 Ducati 1299, enthusiasts have been able to capture every curve and detail — sometimes even with interchangeable magnetic shells and hand-painted finishes. Concept studios push the limits further with 1/4 and 1/3 scale design prototypes, experimenting with resin, acrylic, and rubber. These models not only celebrate motorcycle culture but also serve as valuable design validation tools.

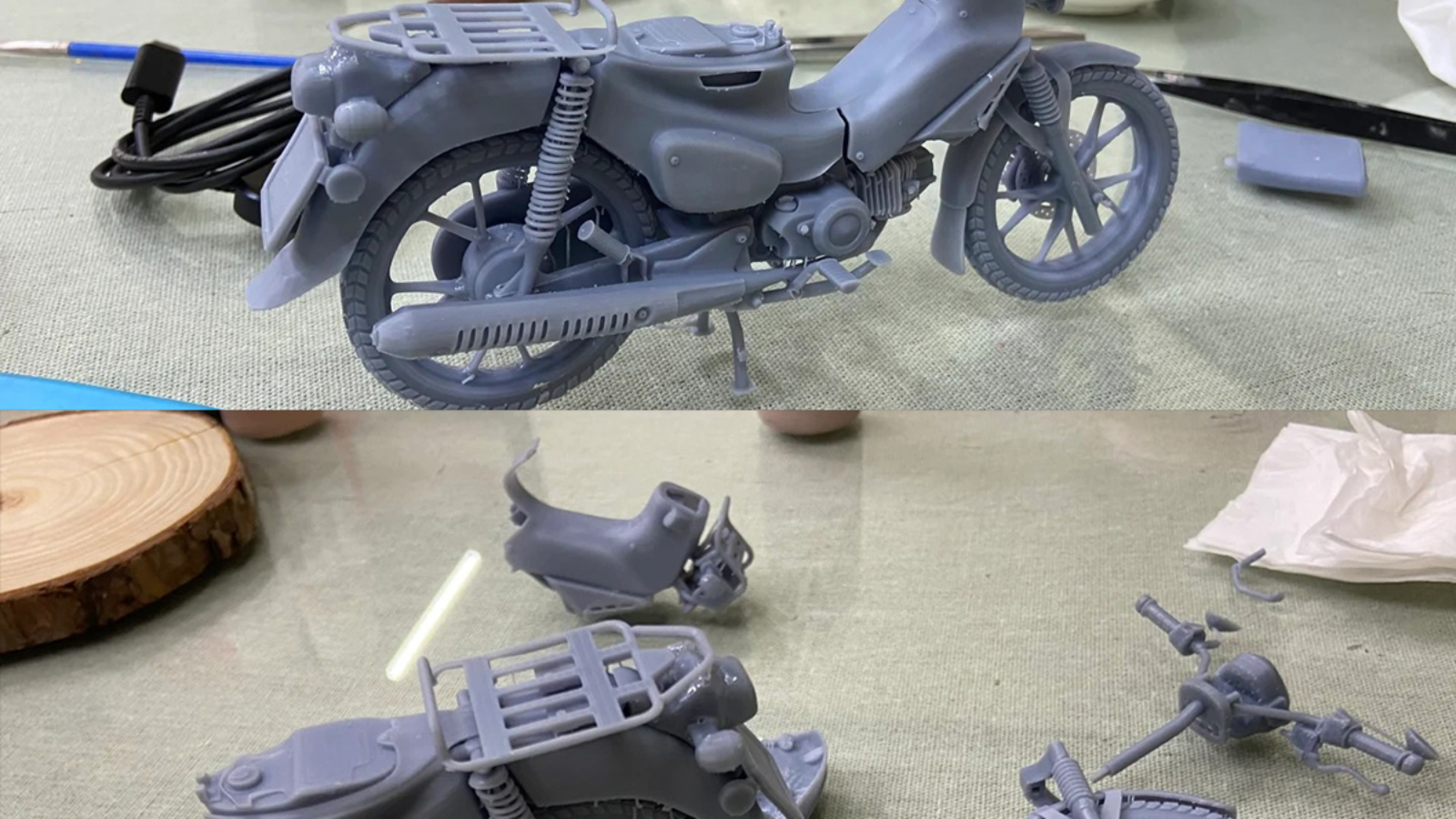

Honda CC110 (1:12, @Xiuxiu): A test print revealed challenges like overly thin brake pads and fragile springs – proving how 3D printing helps detect design flaws early.

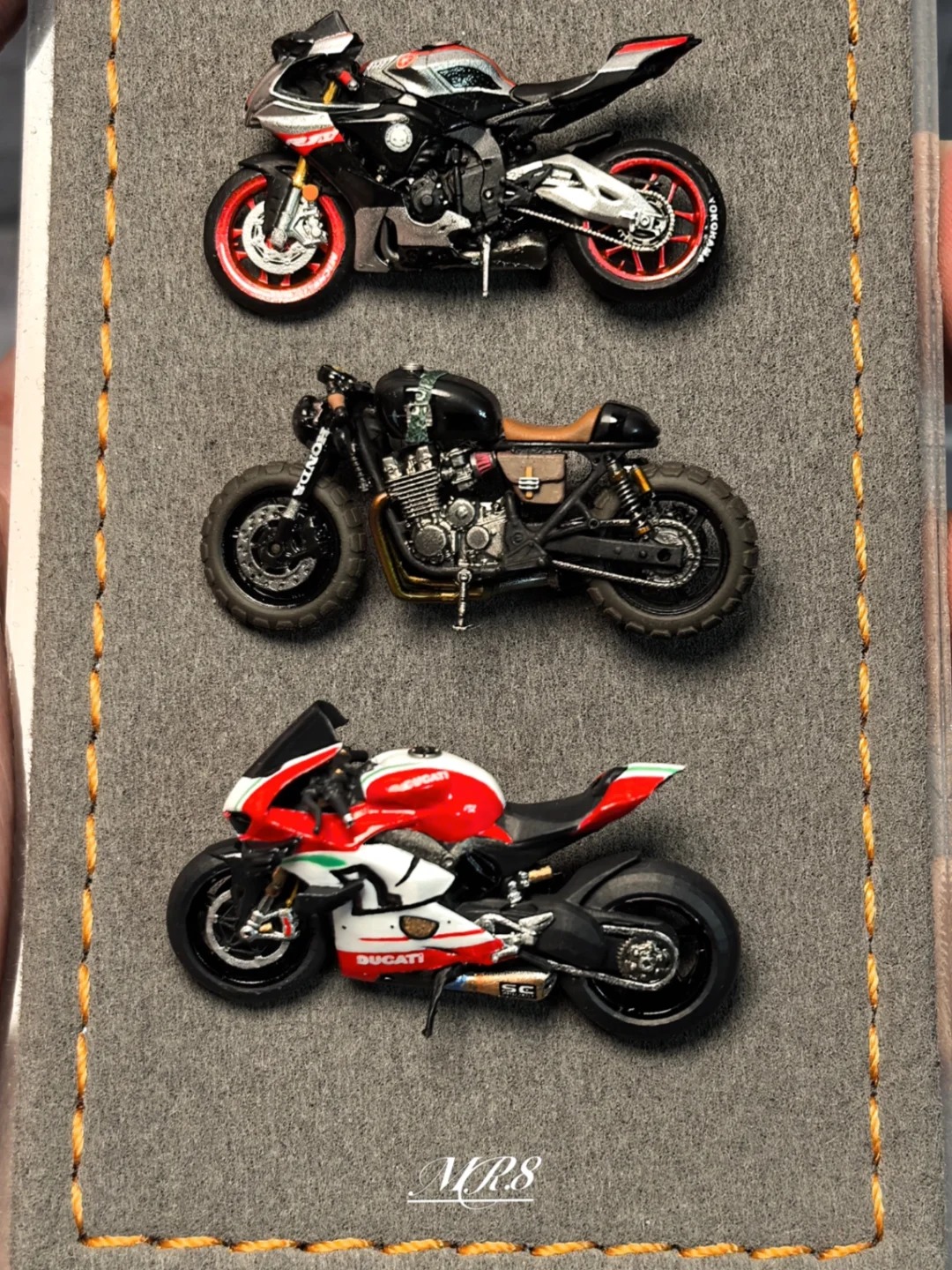

Ducati 1299 (1:64, @Autumn Heart): Detailed white model with paintwork; detachable shell via magnetic connection, complete with internal structures.

1:64 resin motorcycle (@Mr.8): Printed in resin, hand-painted to restore realistic finishes.

Concept Models (@studio O.P.M.D): From 1/4 to 1/3 scale prototypes exploring design direction, made in resin, acrylic, and rubber.

Kawasaki Z650 micro version (@LITMUS) and motorcycle paddock stand (1:6, @Wanwu Lizhi) also showcase hobbyist-level creativity.

Functional Prototypes and Custom Parts

The technology also empowers makers to test real-world applications:

-

Mudguards printed with FDM before being transferred into carbon fiber composites.

-

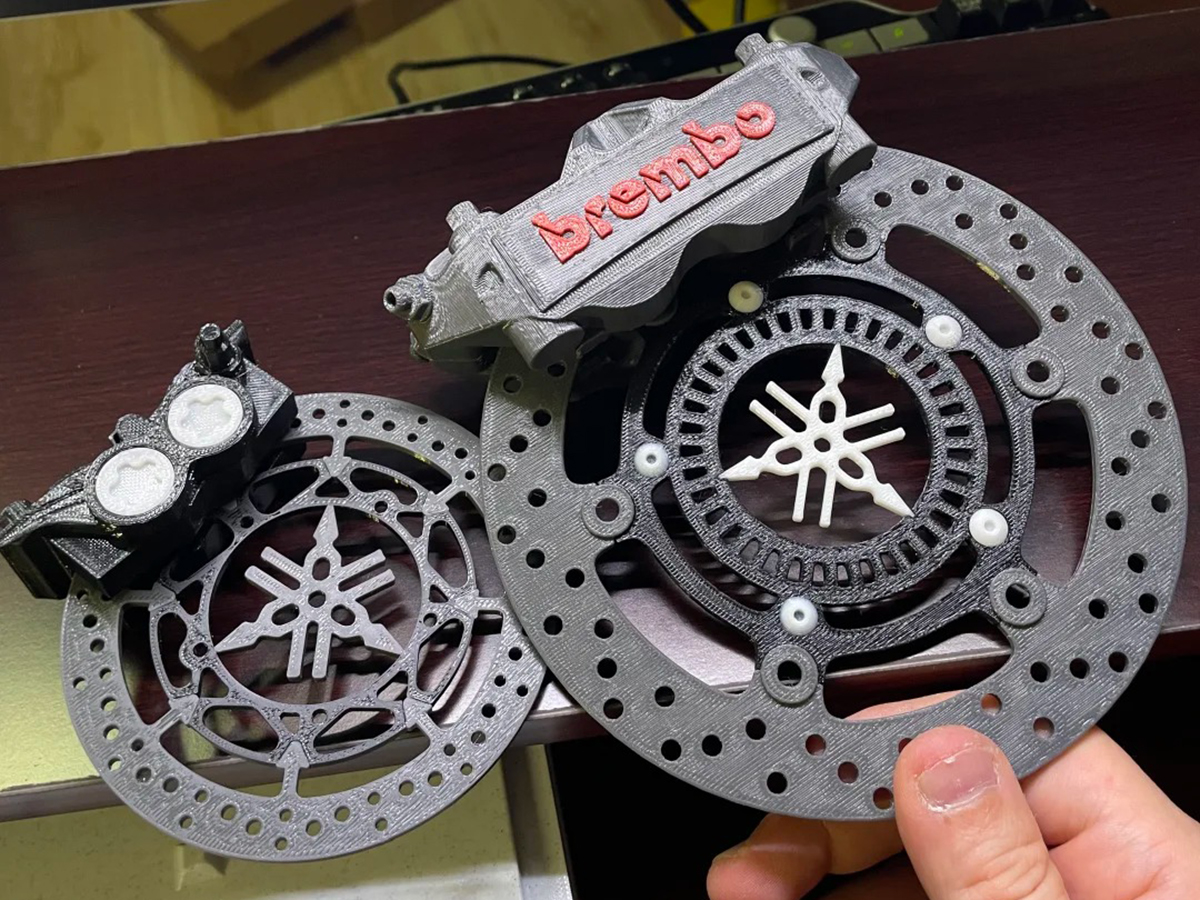

Brake discs and calipers modeled and prototyped in plastic before moving into CNC machining for strength.

-

Custom seat bases 3D printed and later reinforced with fiberglass for a perfect fit.

-

Aftermarket fairing panels produced in PETG with dual finishes, designed for plug-and-play installation.

These projects highlight how 3D printing helps riders validate fit, improve ergonomics, and explore low-volume customization that traditional methods can’t easily achieve.

FDM 3D printed mudguard (Suzuki, @Martin3): Initial prototype printed at home, later planned for composite molding. Highlighted the risks of heat deformation in summer conditions.

Yamaha brake discs and calipers (@Allan.M): Printed prototypes helped enthusiasts understand manufacturing and fitment. Stronger parts required metal machining after CAD verification.

Seat base for Suzuki GS125 (@Huazexi): 3D printed, then reinforced with fiberglass for a custom, more ergonomic fit.

CFMOTO AE4/AE5 cover plate (@andy): PETG industrial print with dual-texture finishes, plug-and-play with factory mounts. Available in multiple colorways for quick customization.

Accessories and Everyday Use

3D printed motorcycle helmet wall mount (@xiying): A practical accessory for storage and display.

Why FacFox?

Although these cases were designed and realized by independent creators, FacFox can help you make yours. Whether you’re building a collectible model, testing a prototype, or fabricating a custom motorcycle accessory, our full-range 3D printing services – from FDM and SLA to SLS, MJF, and metal additive manufacturing – ensure that your ideas are produced with precision, durability, and speed.

👉 Ready to bring your motorcycle idea to life?Partner with FacFox today and turn your concepts into reality.

Leave A Comment