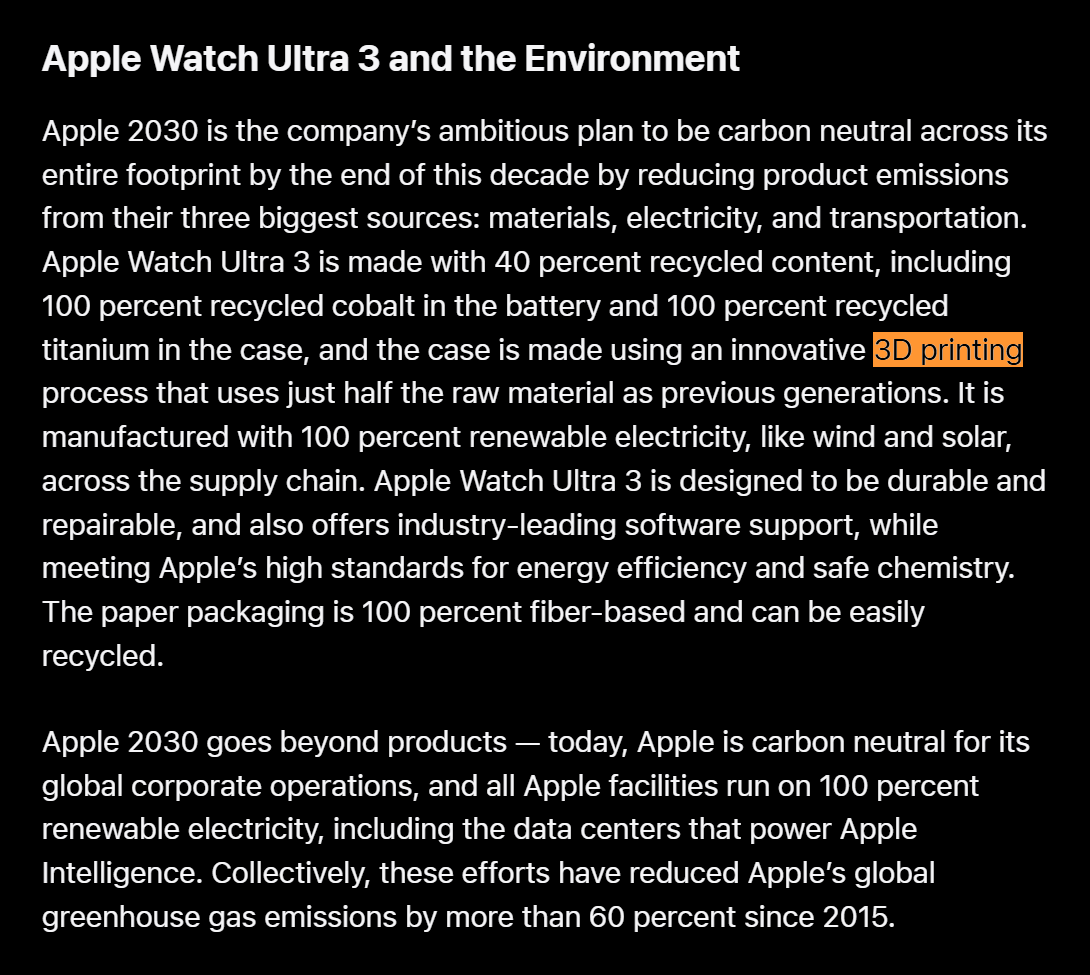

At Apple’s “Awe Dropping” event (Sept 9, 2025), a single understated line from Apple’s VP of Hardware Engineering Eugene Kim may go down as one of the most significant moments in manufacturing history:

Ultra will be available in black and natural titanium made using an innovative 3D printing process that uses 100% recycled titanium and just half the raw material as previous generations.

For the first time ever, Apple officially confirmed the use of additive manufacturing (3D printing) in a mainstream product, one that will ship in millions of units worldwide.

This isn’t just a design change-it’s a paradigm shift.

Why This Matters

- Scale & Visibility: Millions of consumers will now wear a 3D-printed titanium case on their wrist. For an industry often confined to aerospace, medical, or niche industrial parts, this is a watershed moment.

- Material Efficiency: Apple states the new process cuts titanium usage in half, demonstrating additive manufacturing’s unmatched material efficiency.

- Sustainability: By combining 100% recycled titanium with AM’s efficiency, Apple aligns the product with its Apple 2030 carbon-neutral roadmap.

- Market Validation: Apple’s famously strict quality standards signal that AM has matured to meet requirements for precision, durability, and mass repeatability in consumer electronics.

The Challenges of Using 3D Printing for Consumer Electronics

While the news is thrilling, the path to this moment has not been simple. Making electronics with metal additive manufacturing presents several unique challenges:

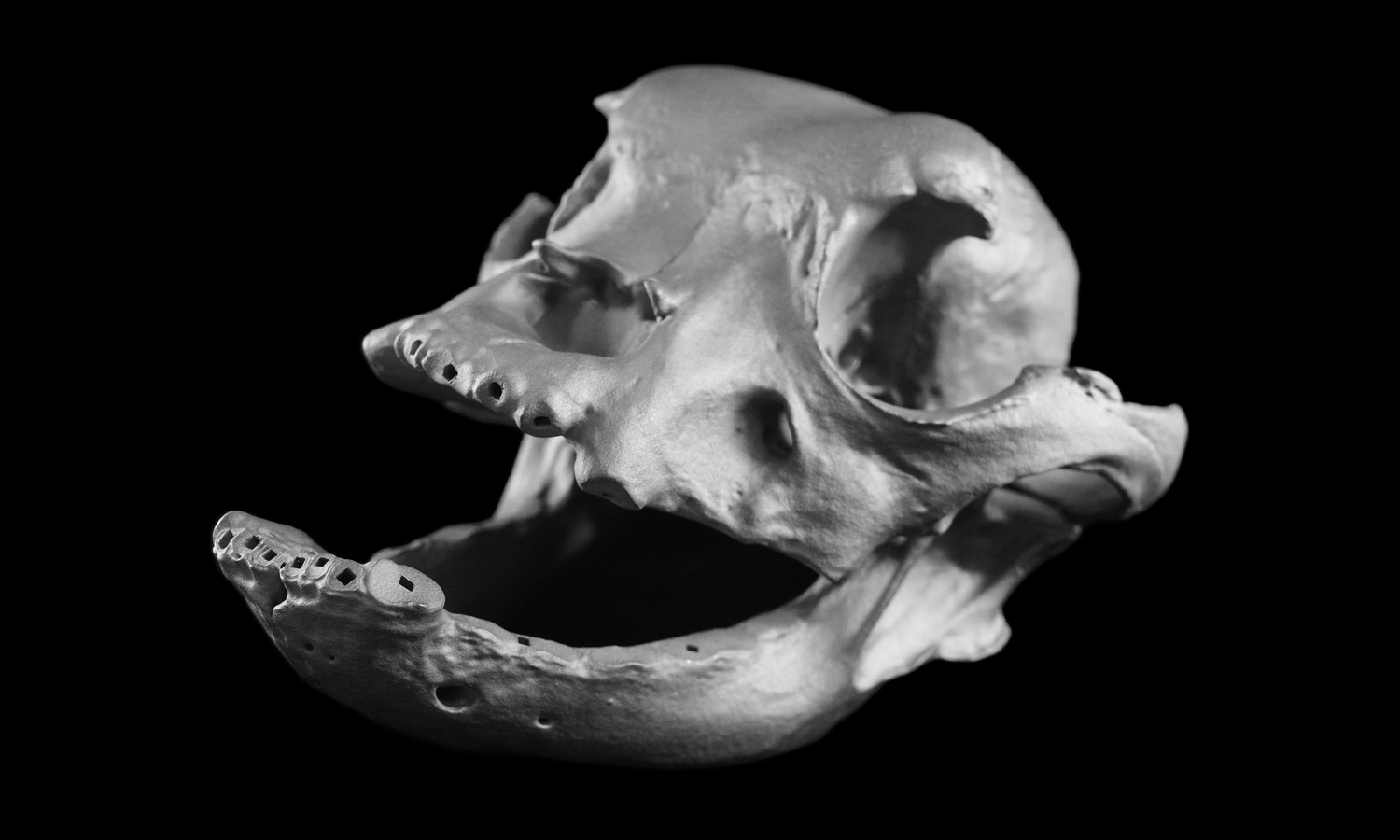

1. Surface Finish

Consumer electronics demand flawless aesthetics – smooth edges, consistent colors, and premium feel.

- Problem: 3D-printed titanium naturally has a rough, matte surface.

- Solution: Apple likely invested heavily in post-processing (machining, blasting, anodizing, or PVD coating) to achieve the Ultra 3’s refined matte titanium finish.

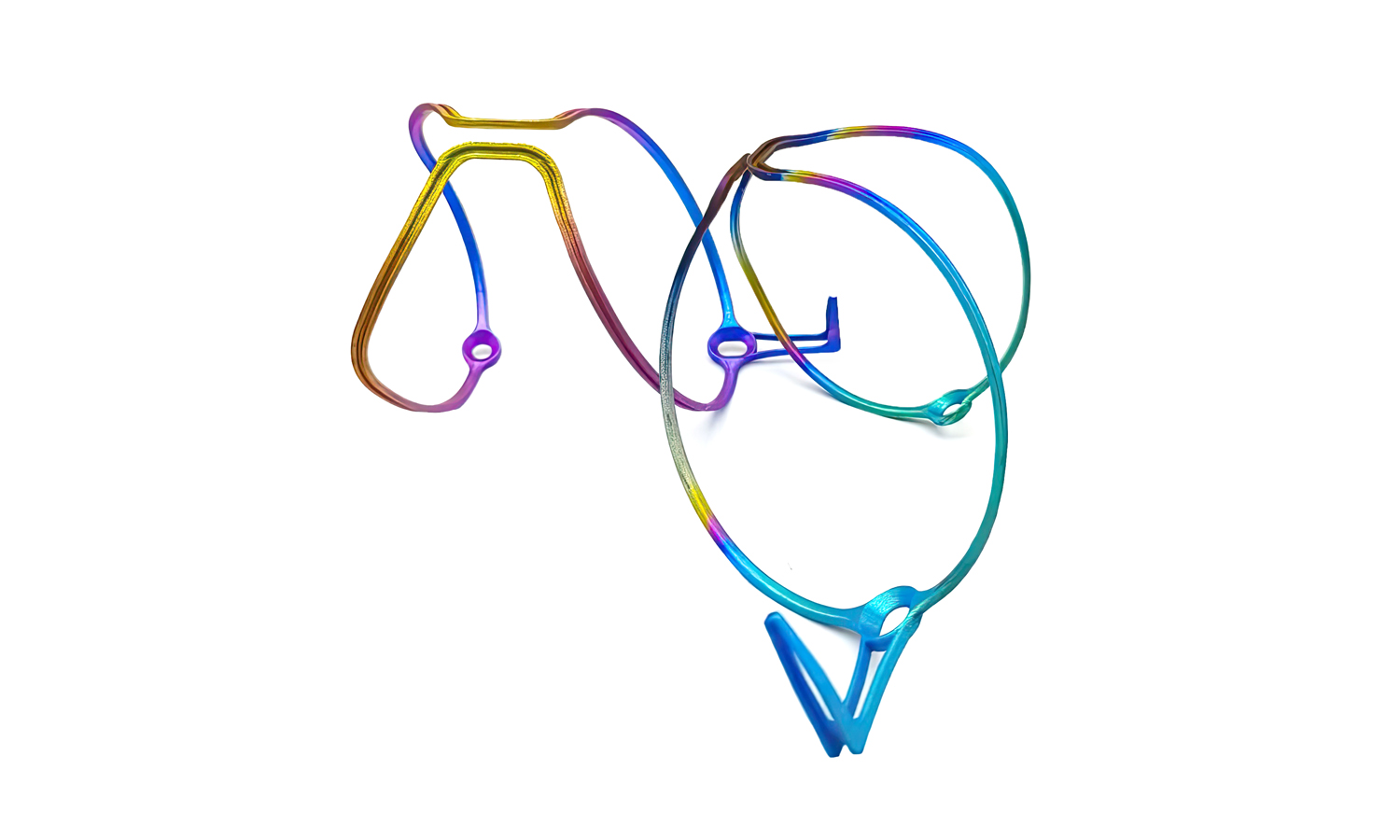

2. Dimensional Precision

A smartwatch case must house sensitive electronics, waterproof seals, buttons, and sensors with sub-millimeter accuracy.

- Problem: Metal 3D printing often involves thermal stresses and shrinkage, which can distort dimensions.

- Solution: Apple’s supply chain (rumored to involve Bright Laser Technologies, BLT) had to develop robust calibration and finishing workflows to guarantee tolerances.

3. Scalability & Throughput

Traditional AM excels at prototypes or small runs, but mass production of millions of units is unprecedented.

- Problem: Build speed and yield rates in AM are bottlenecks.

- Solution: Apple likely deployed multi-laser LPBF systems and optimized build strategies to scale output. This could trigger a wave of investment into high-throughput additive systems worldwide.

4. Material Recycling

Titanium powder is costly and sensitive to oxygen contamination.

- Problem: Maintaining consistent powder quality at scale is difficult.

- Solution: Apple tied the 3D printing workflow into its recycled titanium supply loop, combining sustainability with process control.

5. Supply Chain Integration

Consumer electronics require fast iteration, global logistics, and consistent quality.

- Problem: Integrating AM into Apple’s established machining/assembly ecosystem required rethinking the entire downstream process.

- Solution: By localizing key steps in China’s advanced AM supply chain (post-processing, finishing, coating), Apple gained reliability and scale.

Strategic Significance

Apple Watch Ultra 3’s 3D-printed titanium case is more than a product innovation-it’s an industrial signal:

- Mainstreaming Additive Manufacturing: Apple is telling the world: AM is ready for consumer electronics scale.

- Sustainability Benchmark: Pairing recycled materials with AM efficiency strengthens Apple’s carbon neutrality leadership.

- Industry Ripple: Other consumer brands (Samsung, Huawei, Xiaomi, Garmin) will likely explore AM adoption in their high-end products.

- Material Validation: Titanium, already dominant in aerospace and medical AM, now gains validation in consumer wearables-expanding its market influence.

What’s Next?

We expect Apple’s successful titanium AM adoption to spread across:

- High-end iPhones or iPads: Potential titanium housings or mechanical components.

- MacBook Pro chassis: Large, complex titanium frames could benefit from AM’s material efficiency.

- Accessory components: Buttons, hinges, or structural reinforcements that require both lightweighting and strength.

That said, aluminum products are less likely to adopt AM in the near term due to cost and printability challenges.

FacFox & Titanium 3D Printing

At FacFox, we’ve been helping clients unlock the potential of titanium 3D printing long before Apple’s announcement. Using Selective Laser Melting (SLM/LPBF), we deliver:

- Lightweight, high-strength parts for aerospace, medical, and industrial applications.

- Precision housings and mechanical components for advanced consumer products.

- End-to-end services – from design optimization, through printing, to finishing and quality control.

Apple’s milestone validates what we’ve been building toward: titanium additive manufacturing is not just the future-it’s already here.

👉 Whether you’re designing the next smart device, aerospace component, or medical implant, FacFox can help you realize it with cutting-edge titanium 3D printing at scale and competitive cost.

Leave A Comment