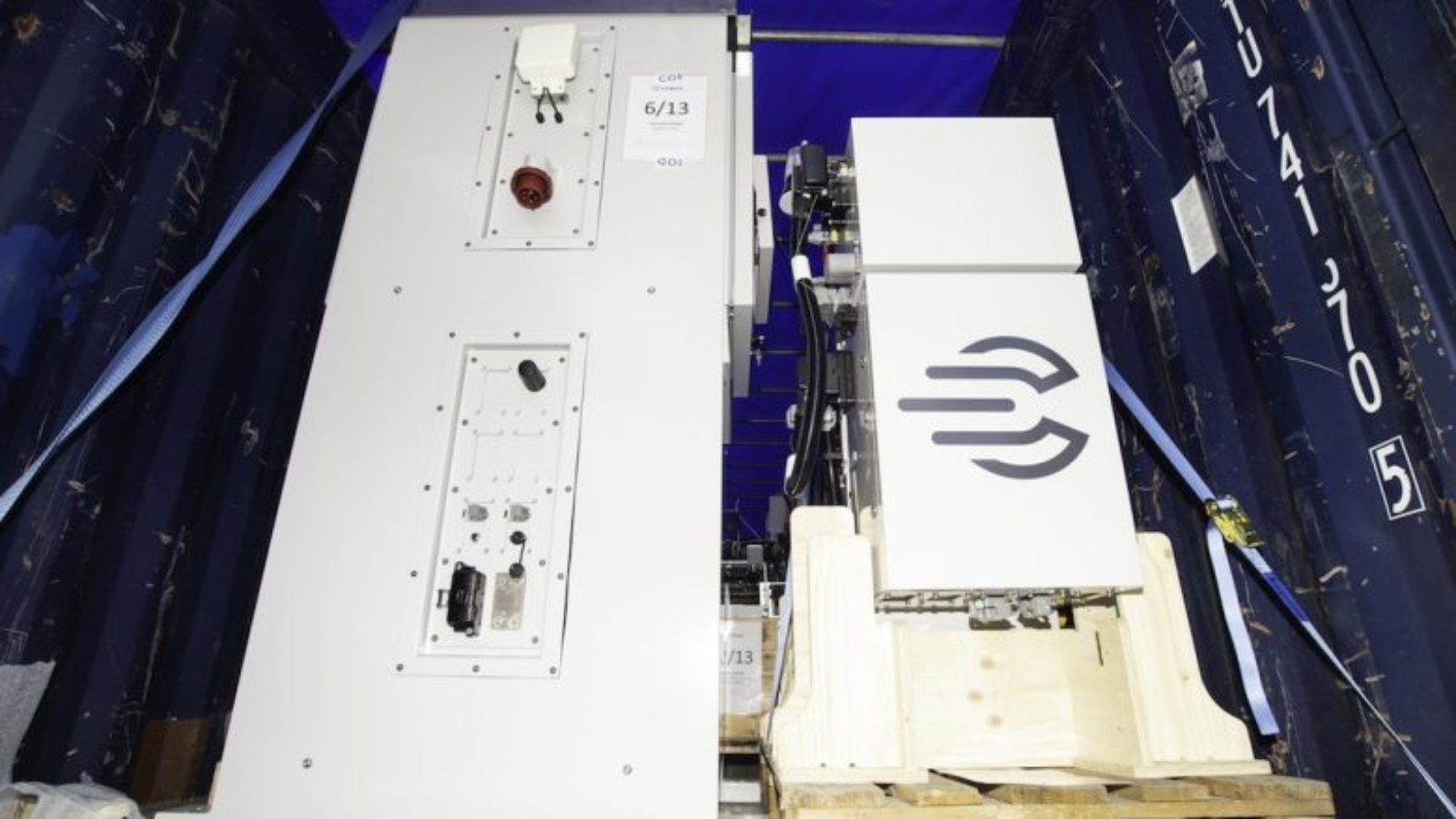

The University of Florida (UF) has acquired one of the most advanced 3D construction printers in the US – COBOD International’s BOD3. This two-story printer, which weighs 27,000 pounds, is the first of COBOD’s third-generation models sold in the US. The printer was shipped to UF in pieces and assembled on campus, where it will be housed in the Weil Hall Structures and Materials Lab within the Herbert Wertheim College of Engineering.

This new technology is expected to revolutionize UF’s approach to construction education and research. It will be used across multiple disciplines within the College of Engineering, including construction, manufacturing, materials science, data analytics, structural health monitoring, and coastal resilience. UF aims to be a hub for innovation in Industrial Manufacturing Construction Engineering, leveraging its proximity to the Space Coast and vast shoreline infrastructure needs. The printer will be incorporated into existing courses and research programs – providing students with hands-on experience in cutting-edge 3D printing technologies.

Manufacturing on Demand

The University of Florida’s College of Design, Construction, and Planning will also utilize the BOD3 for advanced construction technology courses, where students will learn about material selection, design processes, and 3D printing techniques. The integration of this technology into the curriculum is expected to foster interdisciplinary collaboration between students and faculty from both the College of Engineering and the College of Design, Construction, and Planning. The printer has the potential to significantly enhance the quality, speed, and applicability of 3D printed structures – offering a viable alternative to traditional concrete and steel construction.

Beyond education, the BOD3 will serve as a critical tool for research and industry collaboration. Proponents of 3D construction printing highlight its ability to construct homes faster, with less material waste, and at a lower cost compared to conventional methods. This technology not only reduces the physical demands and hazards faced by construction workers but also supports sustainable and eco-friendly building practices. UF’s acquisition of the BOD3 positions the university at the forefront of this evolving field – setting the stage for groundbreaking advancements in construction that could address critical societal challenges, such as affordable housing and sustainable infrastructure development.

You might also like:

Walmart 3D prints 8,000-square-foot building addition in Tennessee: The massive 3D printed build is in use in Athens, Tennessee and functions as an expansion to an existing Walmart site. More specifically, Walmart will use the new space for its Online Pickup & Delivery (OPD) program. The retailer will also reportedly collaborate with Alquist 3D again in the future on a second large-scale printing job.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment