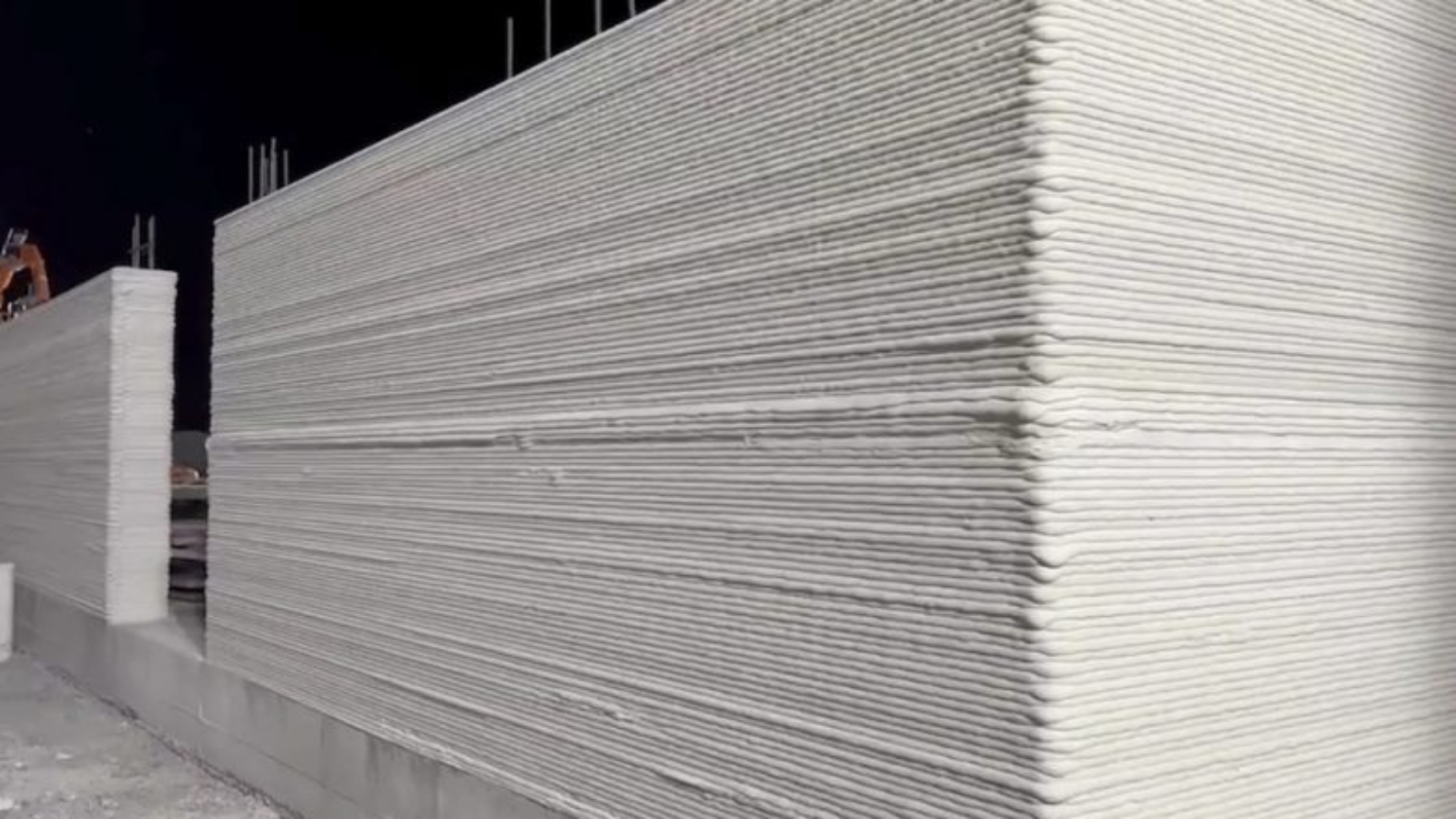

Mega retailer Walmart has commissioned what is being recognized as one of the largest free-standing 3D printed commercial building in the United States. The large-scale construction 3D printing project, which spans nearly 8,000 square feet and is nearly 20 feet tall, was carried out in partnership with Colorado-based Alquist 3D, which specializes in robotic concrete 3D printing.

The massive 3D printed build is in use in Athens, Tennessee and functions as an expansion to an existing Walmart site. More specifically, Walmart will use the new space for its Online Pickup & Delivery (OPD) program. The retailer will also reportedly collaborate with Alquist 3D again in the future on a second large-scale printing job.

“This is the first such facility of its kind and it’s just incredible that it is a reality; this is going to play a major role in the advancement of 3DCP technology,” commented Zachary Mannheimer, Founder and Chairman of Alquist 3D. “And for Walmart to see the value in this project demonstrates how forward-thinking the leadership of this organization is.”

Manufacturing on Demand

One of the key reasons Walmart became interested in exploring the use of construction 3D printing was for the ecological benefits of the technology, driven by significantly reduced material waste. Other reasons included the technology’s ability to erect buildings more rapidly than traditional building methods. Alquist 3D, for its part, was chosen as a partner for its construction 3D printing technique as well as its collaborations within the industry, including with chemicals company SIKA and robotic construction company RIC Technology, who helped bring the large-scale project to fruition.

Mike Neill, VP of New Construction at Walmart, elaborated: “Walmart is always looking to innovate and leverage developing technologies, and we looked at several new building methods and companies for this project. Alquist presented the best ability to work with due to their deep knowledge of 3D materials, robotics, and desire to take on an ambitious and unique project.”

For Alquist 3D, working on the Walmart expansion building was a formative experience that has given the company greater insights into things like the management of material temperates in the summer months, maximizing print speeds and successfully building a structure as high as 20 feet. This experience will inform the company’s future work with Walmart as well as its other construction 3D printing initiatives in the residential sphere. “The knowledge gained on this project will accelerate our work on residential units to fulfill the mission of Alquist,” added , CEO of Alquist 3D. “In order to improve, we tackled the most challenging project we could find and completed it with excellence.”

You might also like:

The University of Florida acquires BOD3 from COBOD: This new technology is expected to revolutionize UF’s approach to construction education and research. It will be used across multiple disciplines within the College of Engineering, including construction, manufacturing, materials science, data analytics, structural health monitoring, and coastal resilience. UF aims to be a hub for innovation in Industrial Manufacturing Construction Engineering, leveraging its proximity to the Space Coast and vast shoreline infrastructure needs. The printer will be incorporated into existing courses and research programs – providing students with hands-on experience in cutting-edge 3D printing technologies.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Tess Boissonneault

Leave A Comment