Dedem (more specifically – Selltek – Dedem’s recently-acquired 3D solutions company), an Italian vending machine company, has signed an exclusive distribution agreement with Tritone Technologies, a provider of metal and ceramic additive manufacturing technology for industrial production. Currently, Tritone is present in Europe, Japan, and North America.

Manufacturing on Demand

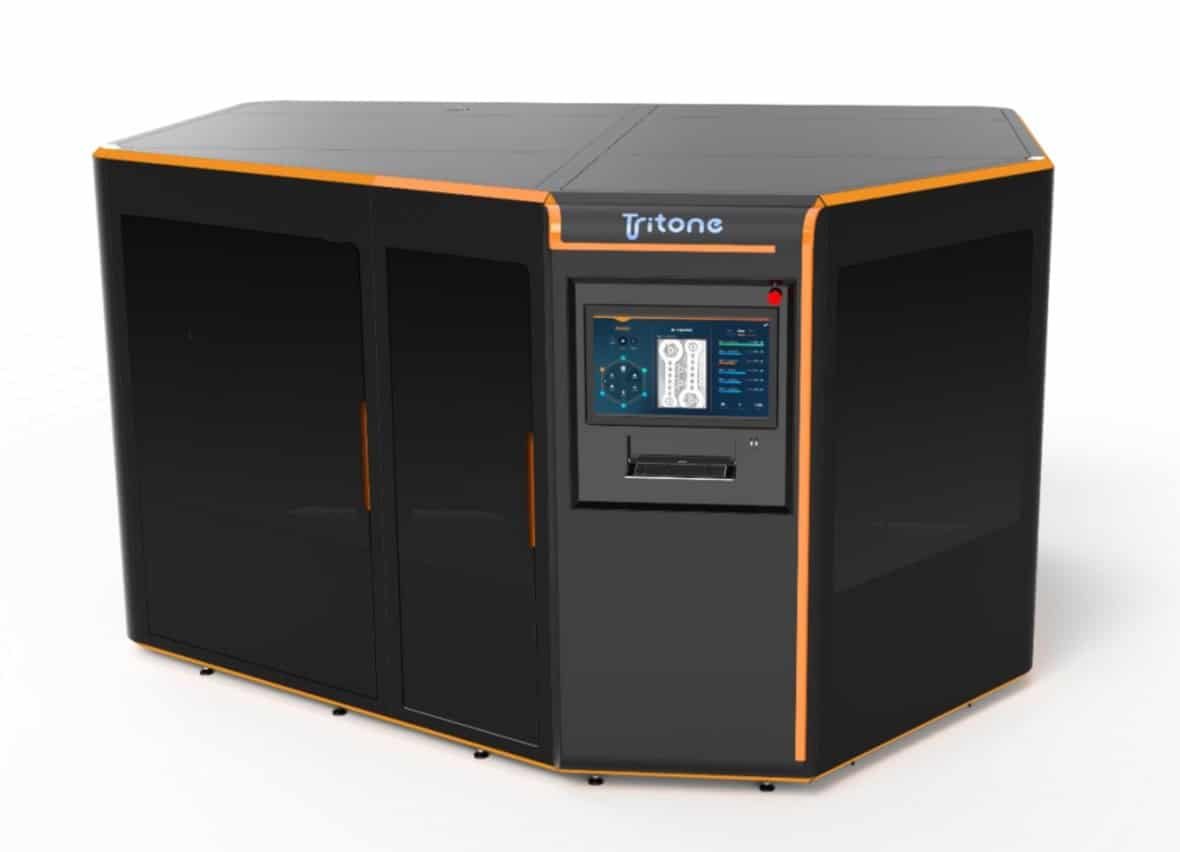

Tritone has two AM systems in the market – the Dominant and the Dim. The systems are based on Tritone’s MoldJet technology, a ‘powder-free’ AM system that enables the production of high-quality metal and ceramic parts at an industrial speed. Designed to produce a large quantity of high-density parts with complex geometries, MoldJet allows a quick and easy changeover between a wide variety of metals and ceramics for parallel manufacturing of parts of various sizes, shapes, and applications.

“Professionalism, excellence, values, and many years of experience in AM were important to Tritone when selecting a partner in Italy,” said Omer Sagi, VP of Products and Business Development at Tritone. “With Selltek, Dedem, we have a competent and strong partner at our side. With more than 20 years of experience in 3D printing, it was a simple choice. We are sure the collaboration between the two companies will bring fruitful opportunities in the country and help Tritone strengthen its presence in the European region”.

You might also like:

CDS joins Stratasys’ GrabCAD Software Partner Program: Developed using AI and machine learning, Cognitive Additive enables users to transform CAD files into manufacturable products, while ensuring the feasibility and quality of parts. This complete, streamlined solution is currently available for Fused Deposition Modeling (FDM) printers, and support for other technologies is planned for the near-future.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment