Desktop Metal, a leader in additive manufacturing technologies for mass production, in collaboration with Sandvik Additive Manufacturing, a leading producer of gas-atomized metal powders, and a top five global automotive manufacturer, has qualified copper alloy C18150 (also known as chromium zirconium copper) for binder jet 3D printing on Desktop Metal’s Production System.

The Production System platform (which is part of Desktop Metal’s binder jet 3D printing systems that also include the Shop System and X-Series platforms) features high-speed Single Pass Jetting (SPJ) technology on two models: the P-1, for research and development of binder jetting projects for serial production, and the P-50, one of the world’s fastest metal binder jet systems – offering some of the lowest costs per part, with SPJ technology.

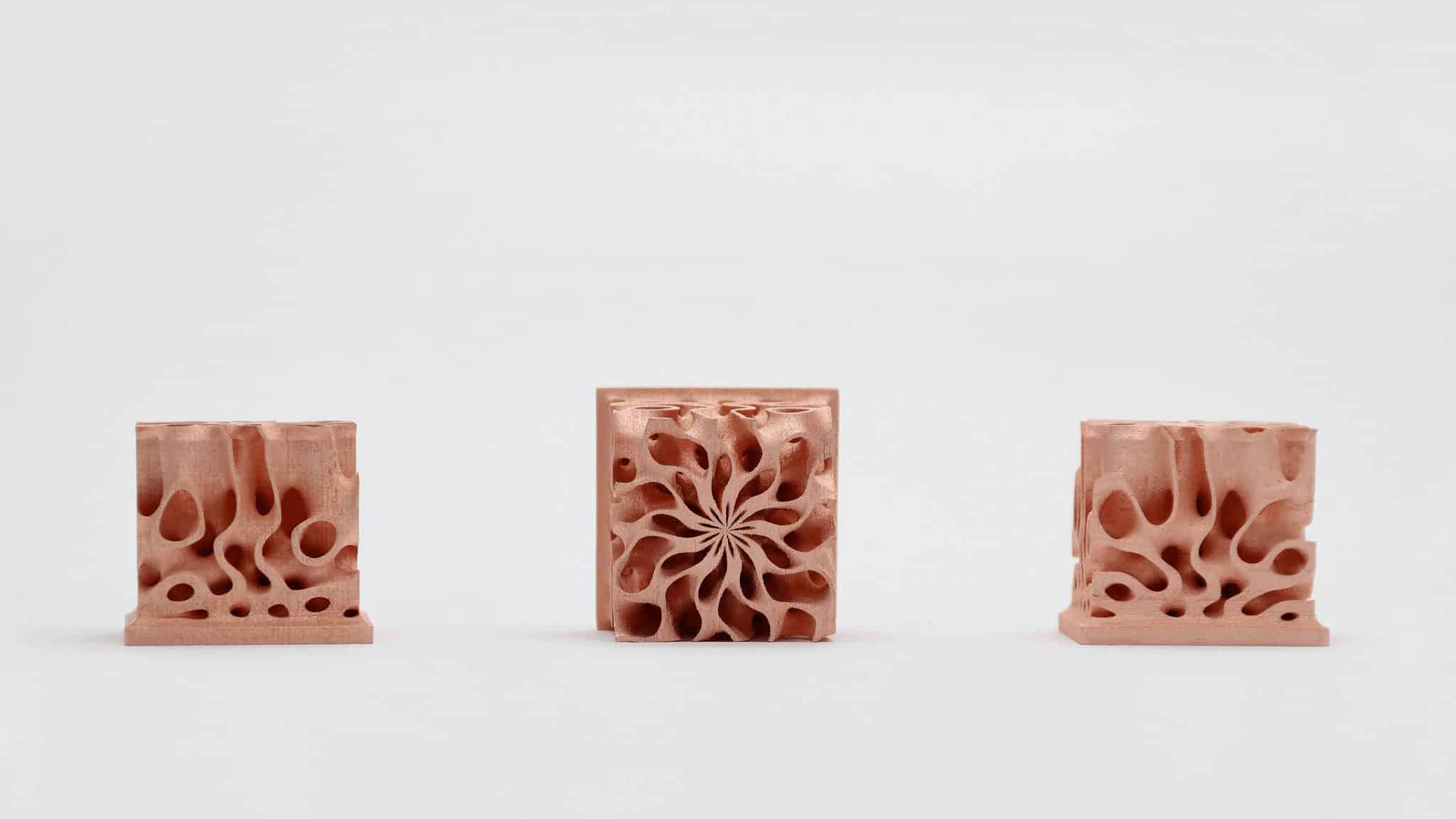

Sandvik Osprey developed and provided C18150 powder that routinely delivered as-sintered densities of 98-99% when printed on the P-1, allowing the automaker to deliver a unique component design that is targeted for high-volume production on the Production System P-50, after additional development.

Manufacturing on Demand

Chromium zirconium copper offers a combination of strength, conductivity, and corrosion resistance that makes it suitable for a wide range of industrial and commercial applications. It’s also able to withstand service temperatures up to 500°C, making it ideal for certain applications in the automotive industry.

“We are proud to announce that chromium zirconium copper is now a qualified material, bringing our world-leading portfolio of binder jet materials to 23 metals,” said Ric Fulop, Founder, and CEO of Desktop Metal. “Simultaneous with our C18150 announcement, we’re also announcing 304L qualification on the Shop System and Ti64 customer qualification on the Production System, which demonstrates how our Team DM experts are collaborating with customers on application-specific material and part qualification projects for future Additive Manufacturing 2.0 production.”

Desktop Metal and Sandvik Additive Manufacturing will discuss details of this joint automotive project during a presentation at AMUG 2023, in Chicago, in March.

You might also like:

Nexa3D acquires what remains of XYZprinting: Founded in 2013, XYZprinting is backed by the world’s leading electronic manufacturing conglomerate, New Kinpo Group, which earns more than 36 billion dollars in revenues annually and has more than 8,500 engineers in research and development across four continents. With nearly two decades of design and manufacturing experience, New Kinpo Group is a recognized manufacturer of many of today’s (2D) printers for both personal and commercial use.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment