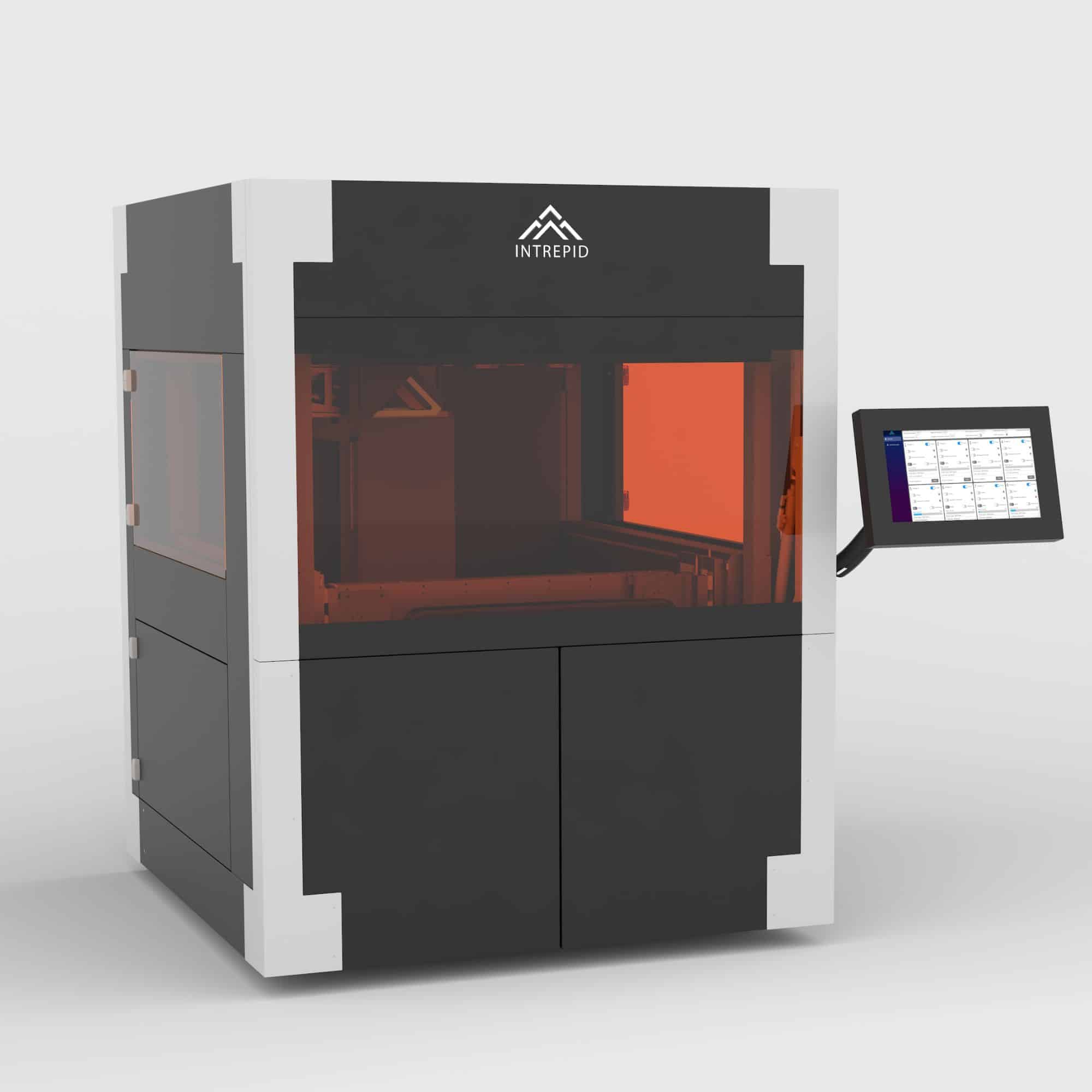

Intrepid Automation, a manufacturing technology company that develops custom, end-to-end solutions for large-scale manufacturing customers using 3D print technology and materials, has launched their ‘Valkyrie’ system – a large-format, industrial-grade, modular tool for manufacturing customers to quickly scale the production of printed patterns, molds, and parts.

The Valkyrie system

The Valkyrie system

The Valkyrie system, with a build area of 660mm x 760mm x 560mm, has customer-validated print speeds of up to 44mm/hour using IntrepidCast LF resins – allowing customers to produce end-use parts up to 10x faster than legacy SLA processes.

Manufacturing on Demand

“Most 3D print manufacturing processes today are slow, expensive, deliver inconsistent accuracy, and are difficult to scale,” said Ben Wynne, CEO of Intrepid Automation. “Our systems solve for all of these challenges.”

Valkyrie systems run on Intrepid’s patented mDLP technology – a process that uses an array of highly-calibrated digital light sources to project a single image at once, rather than tracing image outlines (as it works with legacy SLA processes). Thanks to close partnerships with multiple industrial-scale resin suppliers, the company has been able to develop and validate custom materials for applications in both investment casting patterns (IntrepidCast LF resin family) and rigid part/mold production (Intrepid ThermoRigid resin family) on Valkyrie systems.

You might also like:

Desktop Health and Keystone form dental 3D printing partnership: KeySplint Soft is an FDA-510(k) cleared 3D printing resin for the fabrication of flexible nightguards, dental splints, and bleaching trays. This DLP-optimized resin combines the strength needed to protect teeth with added flexibility for improved patient comfort, all with a transparent and aesthetic appearance.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment