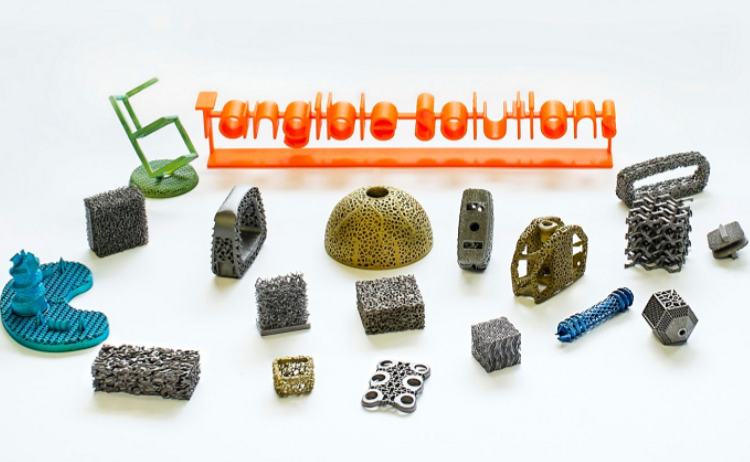

Last month, Fairborn, Ohio-based Tangible Solutions, which was founded in 2013 and manufactures 3D printed titanium orthopedic implants, announced that it was expanding its post-processing equipment portfolio, and its engineering and post-processing staff, in order to meet and cover growing AM production demands due to the COVID-19 pandemic. The ISO 13485:2016 certified and FDA registered 3014273501 company handles every aspect of creating its orthopedic implants, from design support, prototyping, and 510(k) clearance support to 3D printing, post-processing and finishing, and testing both during and after production, and is pleased that it can offer post-processing in-house at its own facility.

Tangible Solutions is committed to high quality, customer responsiveness and engagement, and on-time delivery. By bringing post-processing onsite, the company will be able to make sure that its 3D printed implants are cost-efficient, with good quality and deliverability to clients in the orthopedic field.

“The cost in time and dollars involved in post-processing steps can vary widely; and if these processes are outsourced for a manufacturing project, the costs can be even higher. A contract manufacturer that manages an additive manufacturing project from beginning to end within their facility can save a customer important time and costs when introducing an implant to the market,” Adam Clark, the CEO of Tangible Solutions, said in a press release.

Clark has said in the past that the company’s business model is 100% focused on 3D printed titanium orthopedic implants, and that the AM workflow, FDA submission process, and post-processing are all handled in-house, as employees there understand the importance of what they’re creating and know how to best support customers. Medical devices like implants must be biocompatible, extremely clean, and very smooth; according to a recent study by Fraunhofer IAPT, “metallic 3D printed parts often do not meet the surface quality requirements,” which makes finishing critically important in this sector. It’s also important to achieve repeatability and traceability, as the medical field has extremely high standards in terms of material and device regulations.

Tangible Solutions says that it’s now fully capable of providing all of the necessary post-processing steps for its 3D printed titanium orthopedic implants, which include passivation (making a material unreactive) and laser marking. Often used in combination with passivation in order to support ASTM F86 requirements, marking is required by the medical device industry, since products like implants need to hold up in a variety of environments throughout its lifetime.

“The addition of Laser marking and passivation to Tangible’s list of services almost completes our journey to becoming a full end-to-end contract manufacturer of 3d printed Titanium orthopedic implants. We continue to strive toward zero outside services at a rapid rate,” explained Tangible Solutions COO Chris Collins.

“Tangible exclusively manufactures implants via Titanium 3d printing (Ti-6Al-4V ELI). Throughout the manufacturing process flow, those implants come into contact with various manufacturing materials and surface contaminants that are removed via passivation as well as our proprietary finishing process, which is vital to creating a legible and durable marking.”

Leave A Comment