The European Union has taken a critical interest in regulating 3D printed toys. As 3D printing continues to pick up steam, impacting nearly every business in different industries, security is getting more of an issue. From the 80s, with the beginning of SLA 3D printing, many electronic manufactures were utilized for rapid prototyping using a restricted selection of applications and materials (normally photopolymers) accessible to consumers.

There are new substances available on the industry as researchers and users around the globe continue to forge forward, creating new techniques to fabricate complicated geometries, whether to get pieces, and overcoming barriers. This does not indicate all 3D printing substances are safe to work with — or that wiring and structures may not lead to a potential hazard. Kids can be hard on toys, like swallowing some tiny pieces and choking, or getting poisoned.

Toy safety issues impact the entire industry, but basic measures have been taken for the “general risks” for children and anyone who may come into contact with toys, as well as for “special risks” such as fire, chemical substances, radioactivity, electrical problems, etc. The European Union provided recommendations to 27 countries and oversaw the innovative radar platform-recently named WAZP as a key innovator. Although safety is the main focus, the goal here is to create a solid and innovative industry with a strong supply chain, which means that quality products must be at the center.

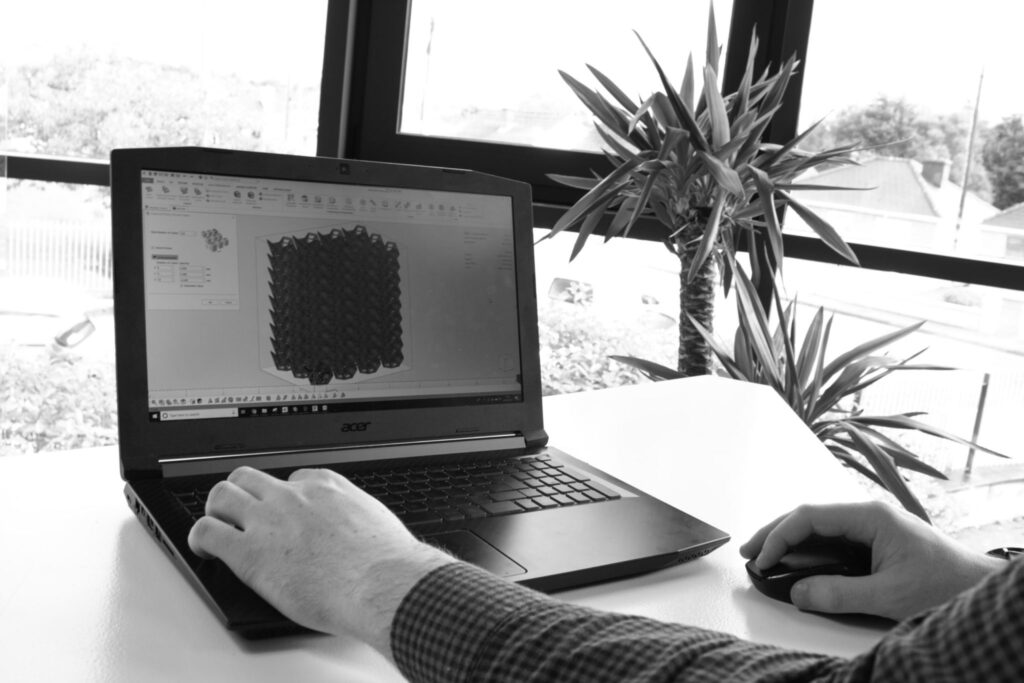

The platform is used to highlight new concepts and the inventors behind them and is funded by the European Union and other framework programs around research and innovation, which usually include consumer products, manufacturing, product distribution, and retail applications. As a global supply chain company for additive manufacturing, WAZP is of course familiar with most of these industries. The Tralee-based company in Ireland was commissioned by the University of Limerick in the Horizon 2020 iBus project, which is known for its Internet business model focusing on toys and furniture. The project is called the Horizon 2020 iBus project.

The University of Paderborn in Germany is also recognized as a key innovator, and the two companies will oversee the creation of “an innovative and high-confidence quotation model for the safety of AM toys.”

Four levels created by Innovative Radar will be explored:

- Value creation opportunity

- Technical readiness

- Business readiness

- Market readiness

WAZP will provide their experience in creating successful models for the 3D printing supply chain, including providing “value” to stakeholders such as toy suppliers, manufacturers, distribution companies, shops selling toys, and consumers. In these business models, sustainability is the key goal to enhance the supply chain within the 3D printed toy industry.

The success of WAZP lies in providing a business model that can provide customized supply chain strategies. Their team firmly believes that they can produce complex, high-quality designs within a “waste-free culture.” The University of Limerick, Paderborn University and the European Union will continue to conduct research and development. Find information about innovation radar and EU funded projects here.

3D printing in the toy industry has brought many new concepts and products to children and consumers of all ages, from spinning tops to train accessories, Lego blocks, and even karts and so on.