3DP4ME, a Jordanian non-profit organization using 3D printing to meet human needs, and World Wide Hearing (WWH) are seeking to raise $200,000 to provide 3D printed hearing-aid molds in the Middle East.

The partner’s previous goal of $100,000 has been increased to develop and manufacture thousands of hearing aid molds a year which will potentially be available worldwide. This new fundraiser has currently accumulated $50,567 in donations.

The Hearing Express Project

Hearing-aids must be tailored to its user to prevent sound leakage and provide maximum comfort. Customizable 3D printed hearing-aids have demonstrated the ability to improve conventional devices to isolate speech and reduce background noise.

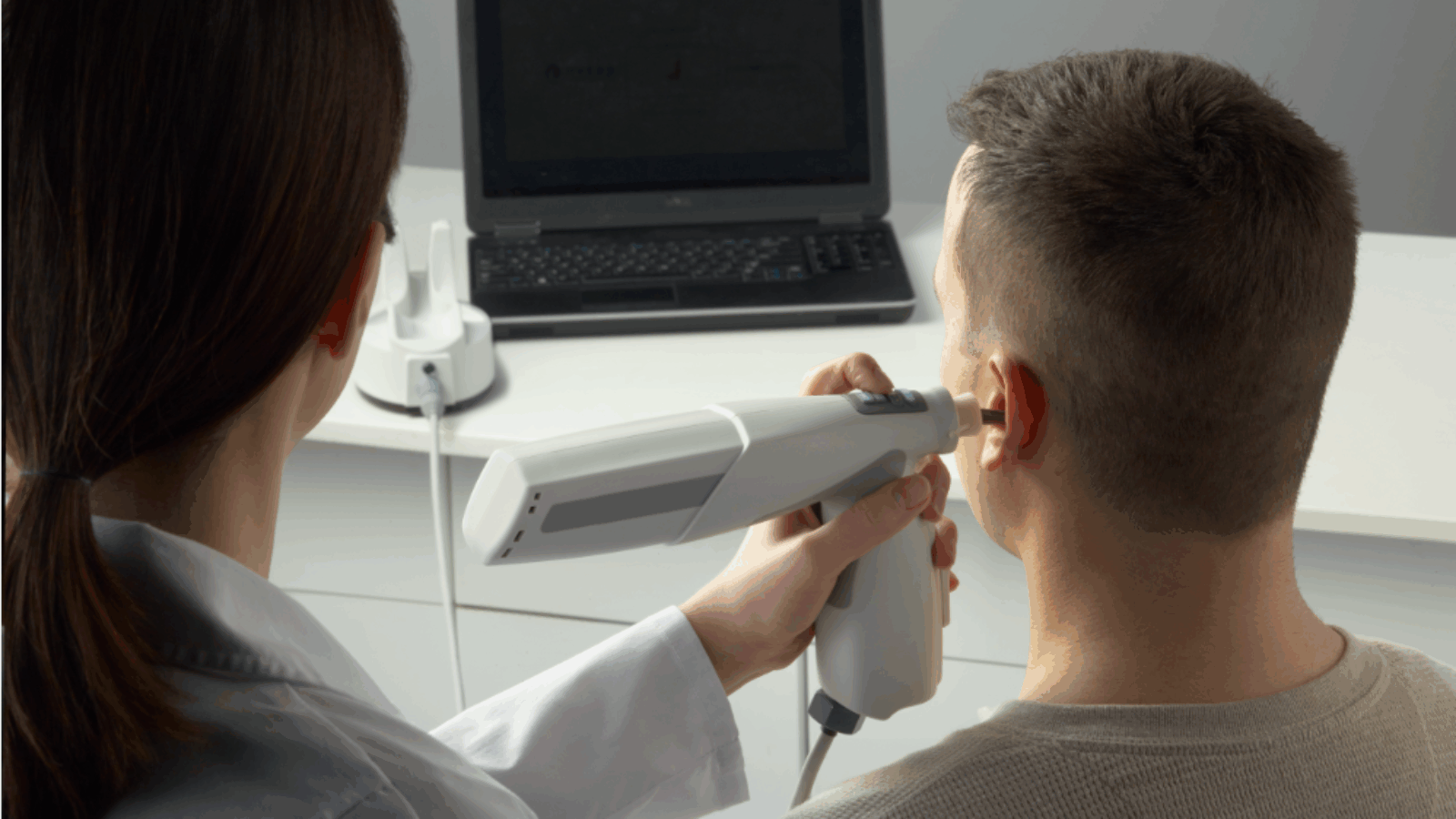

Using a portable Lantos 3D Ear Scanner, 3DP4ME and the WWH aim to visit clients in their homes, villages, and refugee camps to collect data for a personalized 3D printed hearing aid ear mold.

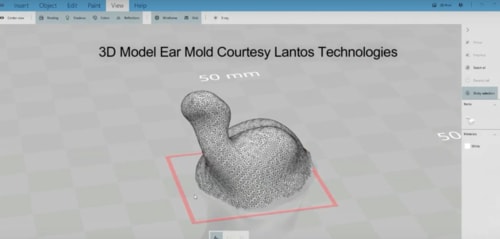

“Once we complete a 3D scan of our client, a 3D model is created in real-time on our internet cloud. Meanwhile, back in the lab, our 3D modeler can immediately start preparing the STL files for 3D printing,” stated Andrew De Carpentier, Head of the Hearing Express Project at 3DP4ME.

The molds are produced on the ASIGA PRO 2 3D Printer using SLA. This system is capable of manufacturing up to 35 ear molds in one hour, a significant improvement from making 3 or 4 ear molds by hand in a day.

Manufacturing on Demand

Combatting hearing impairment

The WWH and 3DP4ME have set the objective of producing 12,000 hearing aids to 4,000 individuals in need of hearing aids. According to the partners, whilst the molds for the hearing-aids are 3D printed, the technology inside the device remains the same.

The ultimate goal of this project is to enable children who are hard-of-hearing to enroll in mainstream education and improve the potential for future employability. Furthermore, the Hearing Express Project will seek to facilitate inclusion, employment and full participation in society by elderly persons who are also hard-of-hearing.

This is said to dramatically boost the hope of living a functional life for children and adults, “enabling them to better contribute to the wealth of the nation.” As such, 3DP4ME intends to raise $200,000 for its lab, staff, materials, and training.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Tia Vialva

Leave A Comment