3D printing is gaining momentum in the construction industry. Both on-site and in the factory, static and mobile robots print materials for use in construction projects, such as steel and concrete structures. This new approach uses flying robots, known as drones, that use collective building methods inspired by natural builders like bees and wasps.

The Aerial-AM drones in the fleet work co-operatively from a single blueprint and adapt their techniques as they go. They are fully autonomous while flying but are monitored by a human controller who checks progress and intervenes if necessary, based on the information provided by the drones.

“We’ve proved that drones can work autonomously and in tandem to construct and repair buildings, at least in the lab. Our solution is scalable and could help us to construct and repair buildings in difficult-to-reach areas in the future,” said Lead author Mirko Kovac, Professor at Imperial’s Department of Aeronautics, and Head of Empa’s Materials and Technology Center of Robotics.

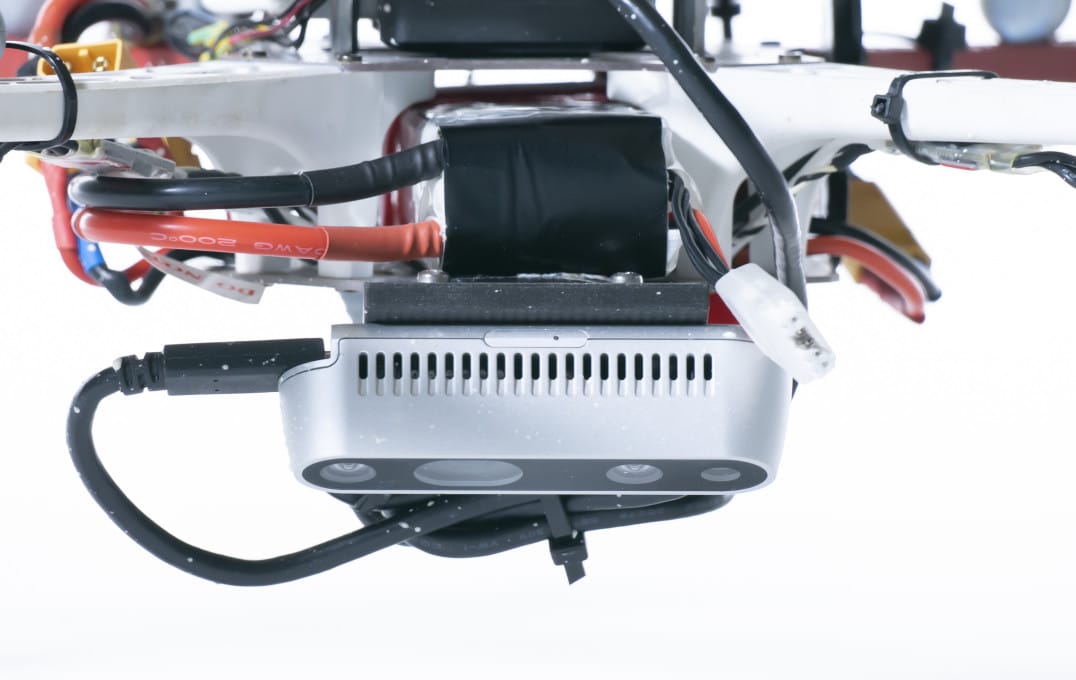

Aerial-AM uses both a 3D printing and a path-planning framework to help the drones adapt to variations in the geometry of the structure as the build progresses. The fleet consists of BuilDrones, which deposit materials during flight, and quality-controlling ScanDrones that continually measure the BuilDrones’ output and inform their next steps.

Manufacturing on Demand

To test the concept, the researchers developed four bespoke cementitious mixtures for the drones to build with. Throughout the build, the drones assessed the printed geometry in real-time and adapted their behavior to ensure they met the build specifications, with a manufacturing accuracy of five millimeters. The proof-of-concept prints included a 2.05m high cylinder (72 layers) with a polyurethane-based foam material, and an 18cm high cylinder (28 layers) with a custom-designed structural cementitious material.

This Aerial-AM technology offers future possibilities for building and repairing structures in tall or other hard-to-access locations. Next, the researchers will work with construction companies to validate the solutions and provide repair and manufacturing capabilities. “We believe our fleet of drones could help reduce the costs and risks of construction in the future, compared to traditional manual methods,” said Professor Mirko Kovac.

The ScanDrone’s camera

The BuilDrone’s nozzle

Co-investigators include Robert Stuart-Smith, Stefan Leutenegger, Vijay Pawar, Richard Ball, Chris Williams, and Paul Shepherd, and their research teams at UCL, University of Bath, University of Pennsylvania, Queen Mary University of London, and Technical University of Munich (TUM). The work was launched by Assistant Professor Stuart-Smith at UCL and University of Pennsylvania, and Professor Mirko Kovac at Imperial College London and Empa after a pilot research collaboration and award for a demonstration on pipeline repair.

This work was funded by the Engineering and Physical Sciences Research Council (part of UKRI), the Royal Society, the European Commission’s Horizon 2020 Programme, the Royal Thai Government Scholarship, and a University of Bath Research Scholarship. The project is also supported by Industrial Partners Skanska, Ultimaker, Buro Happold, and BRE.

You might also like:

SLM Solution and CTC to develop 1.5 meter z-axis NXG XIIE: “We are excited to play a role in this ground-breaking AM advancement,” said Edward J. Sheehan, Jr., CTC President and CEO. “The technical work we are performing for this project includes elements of CTC’s full-service portfolio of AM capabilities including design, testing, post-processing, machining, and qualification.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment