Researchers from George Washington University (GWU) and the Moscow Institute of Physics and Technology (MIPT) have used open-source 3D printing to monitor cardiac arrhythmias otherwise known as an irregular heartbeat.

In a study published in , the researchers sought to create a customizable and cost-effective optical mapping system to understand the relationship between the electrical and mechanical activity of intact hearts.

Such optical mapping systems use the process of perfusion with fluorescent dyes through tissue. “A number of intracellular parameter changes could be tracked this way using high-speed cameras,” the research states; this leads to the mapping of cardiovascular activity.

“The high cost of the equipment and the technical challenges of monitoring multiple parameters of the sample at once and processing the associated signals prevent more widespread use of optical mapping in the biological community.”

3D printed optical mapping

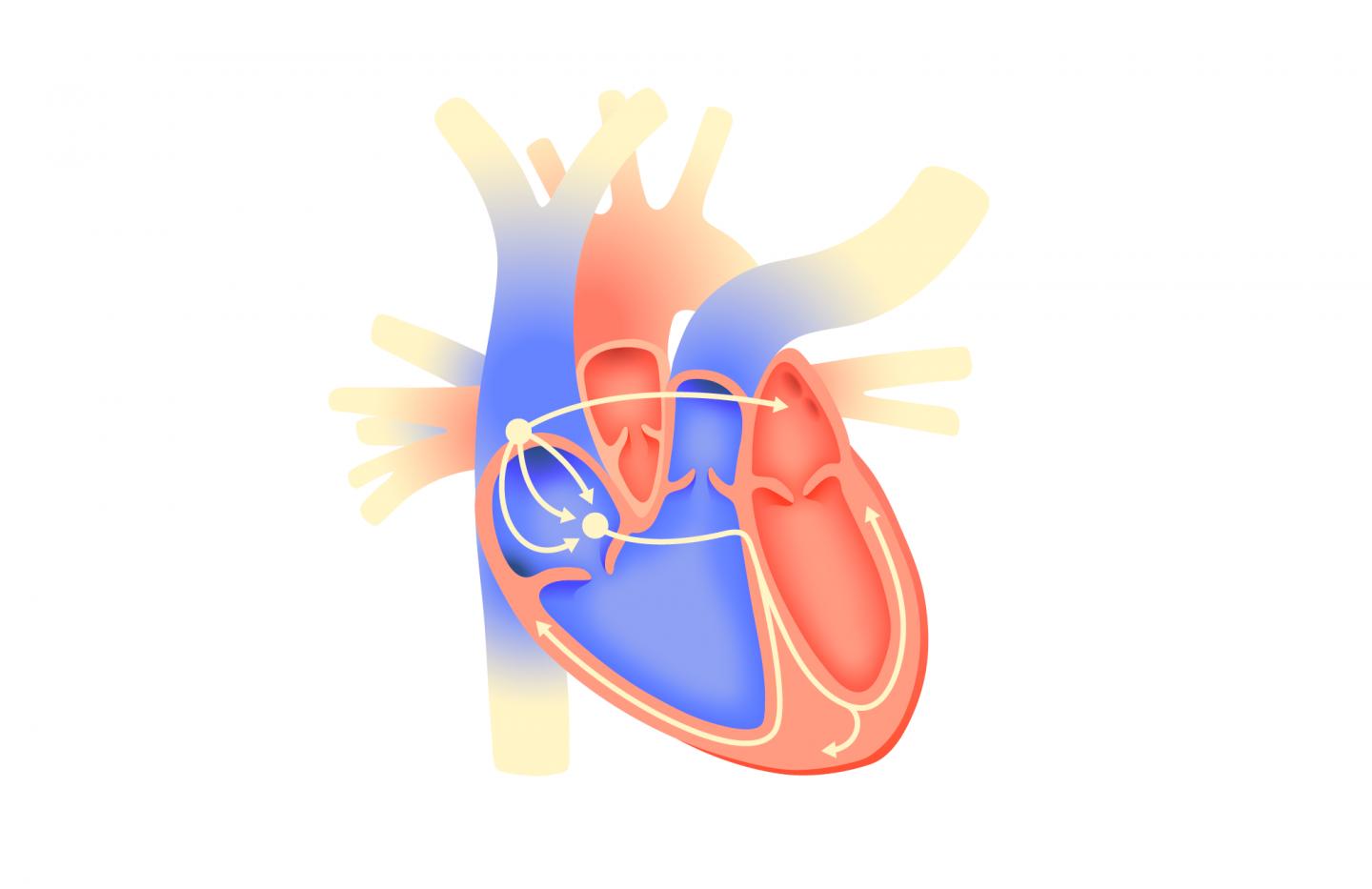

According to the research team, the mapping process uses cardiac excitation; this primarily involves electrical excitation and the variation in calcium concentration which affect blood levels in the heart. “Normally, excitation is initiated by a group of cells in the right atrium, called the sinoatrial node, and spreads through the cardiac conduction system to the atria and ventricles.”

“Abnormalities in propagation, known as arrhythmias, are a leading cause of mortality in Russia and other developed countries.”

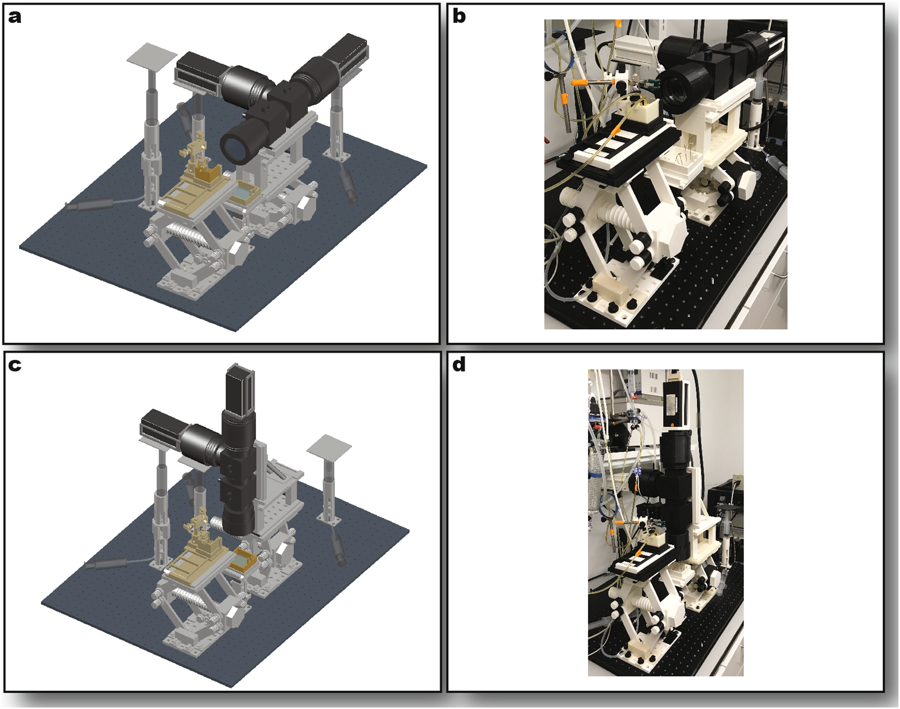

Using the Stratasys Fortus 250mc 3D printer, open-source optical components excluding cameras, lenses, and pumps, were additively manufactured. The researchers have calculated that this system, which operated using Matlab-based multi-signal processing software, could save other researchers up to $20,000 when compared with commercially available products.

“Studies using multiparametric mapping are still uncommon,” explained Roman Syunyaev, a researcher at MIPT’s Human Physiology LabSyunyaev and co-author of this study.

Manufacturing on Demand

“Although the excitation propagation in the heart muscle is associated with an interaction between multiple complex phenomena, it is usually the case that researchers can only measure one parameter.”

It was noted in the study that for the production of the 3D printed mapping system, an industrial-grade 3D printer with a minimum resolution of 0.01in (0.254 mm) is required. Also, ABS was used for the components instead of PLA due to its increased quality and higher melting point – which led to less deformation.

The novel system demonstrated it’s functionality through the optical mapping of whole mouse hearts. It simultaneously recorded voltage and calcium signals within the organ with improved quality of pseudo-electrocardiogram (ECG) traces – a test used to check the heart’s rhythm.

“Not many research teams nowadays can afford the expensive equipment for optical mapping,” stated Professor Igor Efimov, Chairman of the Human Physiology Lab at MIPT.

“Now they can use our designs to recreate an affordable system just like the one we used. A further advantage of our tool is that it offers the freedom to design new experiments on diverse samples.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Tia Vialva

Leave A Comment