Xerox, the American manufacturer of printers and photocopiers, has acquired Vader Systems, a New York-based manufacturer of the liquid metal jet 3D printers.

As previously reported by 3D printing industry, most recently in October 2018, Xerox has long had eyes on additive manufacturing opportunities.

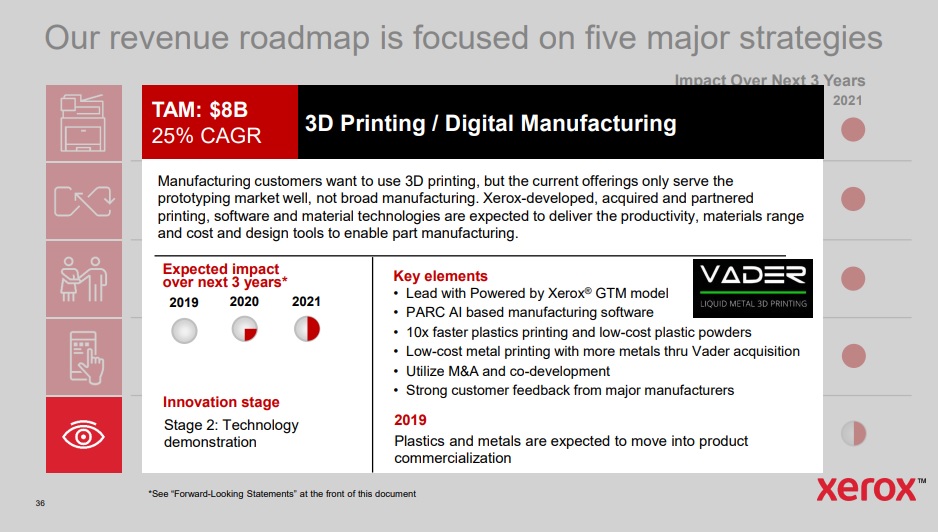

After years of anticipation on its expansion into the 3D printing industry, Xerox made the brief announcement at its Investor’s Day 2019 conference in New York. This acquisition is part of the company’s innovations strategy which aims to access a Total Addressable Market (TAM) of $8 billion for additive/digital manufacturing.

Xerox and Vader Systems declined to provide further details on the acquisition or the longer term strategy for 3D printing covered by Joanne Collins Smee and Steve Hoover during the investor day.

Xerox and 3D printing

In 2016, Janos Veres, the leader of the Palo Alto Research Center (PARC) Novel and Printed Electronics Program at XEROX, explained that the company’s planned transformation would involve 3D printing and Industry 4.0 technologies.

Then in 2017, PARC, was selected by US Defense Advanced Research Projects Agency, DARPA, to develop “a new computational paradigm” that goes beyond the limitations of existing 3D design platforms.

Following this, John Visentin CEO of Xerox announced on an investor call last year that the company is “developing a roadmap to participate in 3D printing.” Visentin stated:

“We are developing a roadmap to participate in 3D printing. We currently manufacture 3D printouts that we OEM where we have differentiated capabilities around print technologies, materials, toner and software that will enable 3D printing to move to the next level of adoption for the production of end-use industrial products.”

Presently, according to the Investor’s Day presentation, Xerox intends to broaden the current offering of 3D printing,i.e., the prototyping market with the new acquisition.

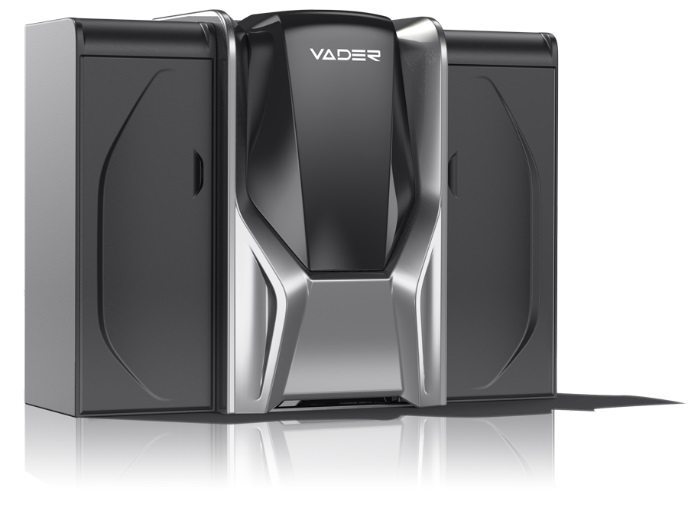

Vader Systems Magnet-o-jet technology

Founded in 2013, Vader Systems developed and patented metal 3D printing technology referred to as Magnet-o-Jet. This process, as described by Zach Vader, co-founder of Vader Systems, “takes in metal wire feedstock that gets melted into a ceramic nozzle.”

“This makes a small pool [weighing] about 2 grams, the metal is always molten in the nozzle and then we use electromagnetism to induce a current and a radial inward force that produces a droplet.”

This is done on each droplet using an electrical pulse at a rate of 1000 times a second, which results in a high deposition rate. The technology is integrated into the company’s first system, the MK1 Experimental metal 3D printer, and its three newer systems, the Vader Polaris, the Magnet-o-Jet Subsystem, and the Ares Microsphere Production System.

Magnet-o-jet technology is said to expand the range of conductive metals used within metal additive manufacturing. Such limitations within industrial additive manufacturing are also being addressed by the University of Nottingham, who established an additive manufacturing research lab in 2015 with custom metal-jetting systems. While the metal prints from Vader Systems remain near net shape, results seen by Industry from the metal jet technology under development in Nottingham are significantly more advanced.

For more updates on the Vader Systems acquisition by Xerox, subscribe to the Industry newsletter, follow us on Twitter and like us on Facebook.

Also, nominations for the Industry Awards 2019 are open. Let us know the enterprises, technology and individuals leading the additive manufacturing sector.

Why not visit Jobs to commence your career in additive manufacturing?

Featured image shows the magnet-o-jet liquid metal 3D printing subsystem. Image via Vader Systems.

Leave A Comment