Global rail and transit manufacturer Wabtec has become one the first customers for the H2 binder jet metal 3D printer from GE Additive. The Pennsylvania-based company plans to use the 3D printer to manufacture large, complex parts, growing the use of additive in the transportation industry.

Bringing 3D printing to the rail industry

Wabtec provides parts to most major rail transit systems in the world. Its portfolio includes a number of highly-engineered metal components and systems which it which it produces in over 100 manufacturing plants. So far, the company has identified that additive technologies could be used in the production of up to 250 components in its product lines by 2025.

With GE’s H2 Binder Jet Printer the company will be able to create spare parts to order, thereby reducing customers’ inventory requirements while supplying them within very short lead times. The aim is to keeping rolling stock on the move.

Commenting on purchase Philip Moslener, global director of the WabtecOne Platform & Applied Innovation said, “Additive is one of the key technology pillars for our company and central in our efforts to drive innovation in the industries we serve.”

Adding, “This binder jet machine will help us design and produce reliable, low-cost components for our current and developmental engines, locomotive, transit and mining programs.”

Investing in Binder Jet technology

Binder jetting processes use two materials – a powder base, and liquid binder. The material H2 currently uses for producing parts is Stainless Steel 316, however other materials are under development including low carbon steels.

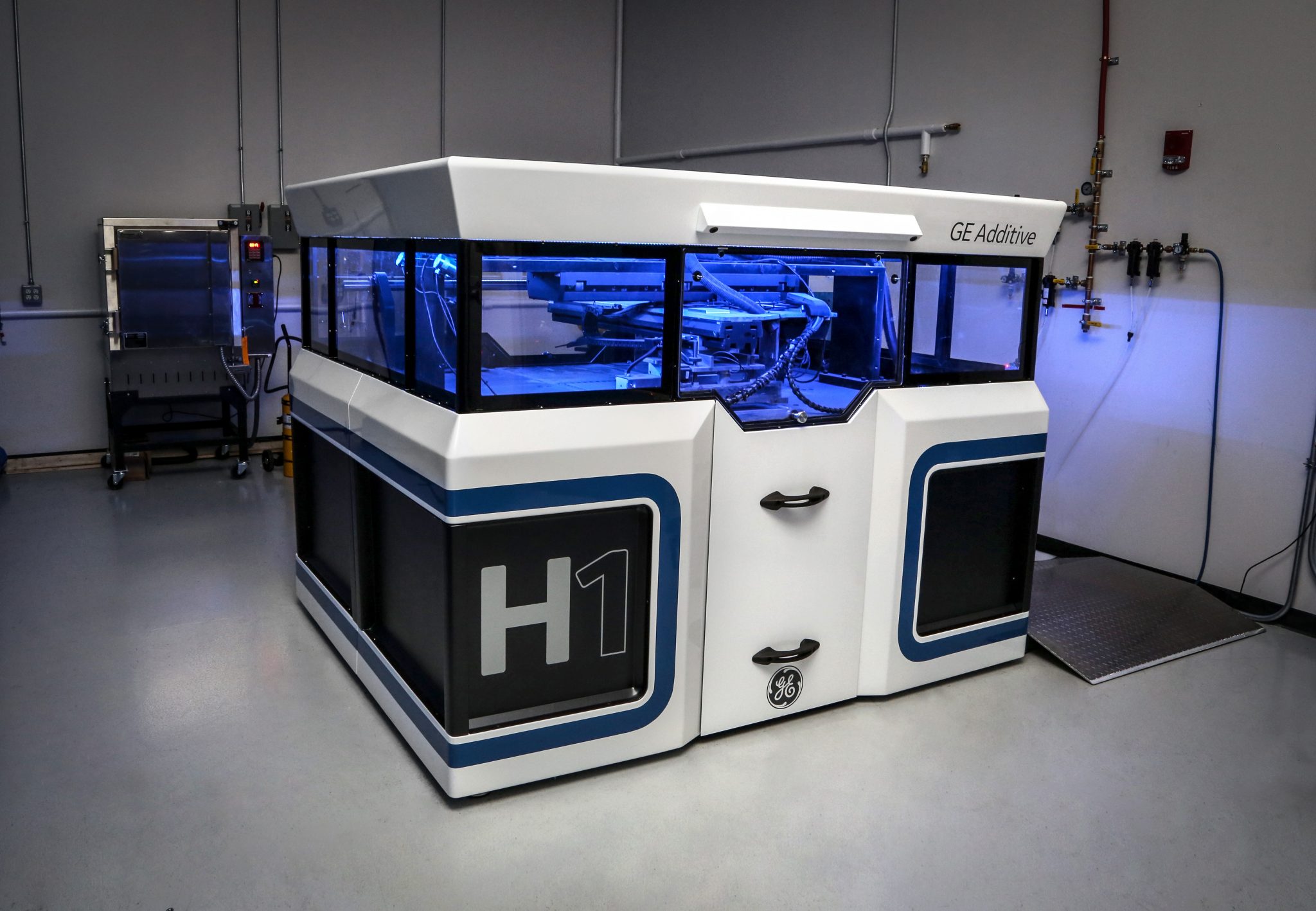

The H2 is a successor of GE’s H1 binder jet metal 3D printer, first teased by the company in 2017. Since that point, GE binder jet development of the H2 has remained largely in stealth mode, only recently releasing a beta. GE expects the H2 to be commercially available in early 2021.

Last month, American manufacturer and remanufacturer of engines Cummins Inc. became the first company to adopt GE Additive’s beta version of the H2 metal binder jet 3D printing technology.

“Throughout 2018, a multi-disciplinary team at GE Additive developed the second generation H2 binder jet beta machines. Today, parts are being printed on those machines, which we understand provide the largest format and fastest build speed currently on the market,” said Josh Mook, innovation leader at GE Additive.

Additive manufacturing for the railway industry

The rail industry is increased using additive manufacturing, for example the Mobility Goes Additive project originating at Deutsche Bahn. The project brings together a network of companies from the mobility and logistics business in order to advance the application of additive manufacturing, with a particular focus on the production of spare parts for the transportation sector.

Elsewhere, initiatives such as the instillation of Stratasys F900 3D printer in Bombardier’s Hennigsdorf facility in Berlin, and a partnership from Angel Trains and ESG Rail and Stratasys to 3D print replacement parts for trains are also helping additive to make gains in the rail sector.

Wabtec’s H2 machine is currently located at GE Additive’s labs in Cincinnati, where teams from Wabtec have been working on technology development. The machine is due to be relocated to their Grove City, Pennsylvania facility later this year.

Vote for your Innovation of the Year in the 2019 Industry Awards.

Subscribe to the Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook. Looking for a career in additive manufacturing? Visit Jobs for a selection of roles in the industry.

Featured image shows the H2, a binder jet 3D printing system from GE Additive. Image via GE Additive.

Leave A Comment