TRUMPF has been developing lasers for fabrication equipment for some time, but, though they have licensed their technology for use in 3D printing previously, got into the development of actual printers last year, when they formed a joint venture with Sisma, Italy’s largest laser system maker. Sisma created metal 3D printing machines under the MySint100 line. Now, they have announced that they will be launching new systems at formnext in Frankfurt next month.

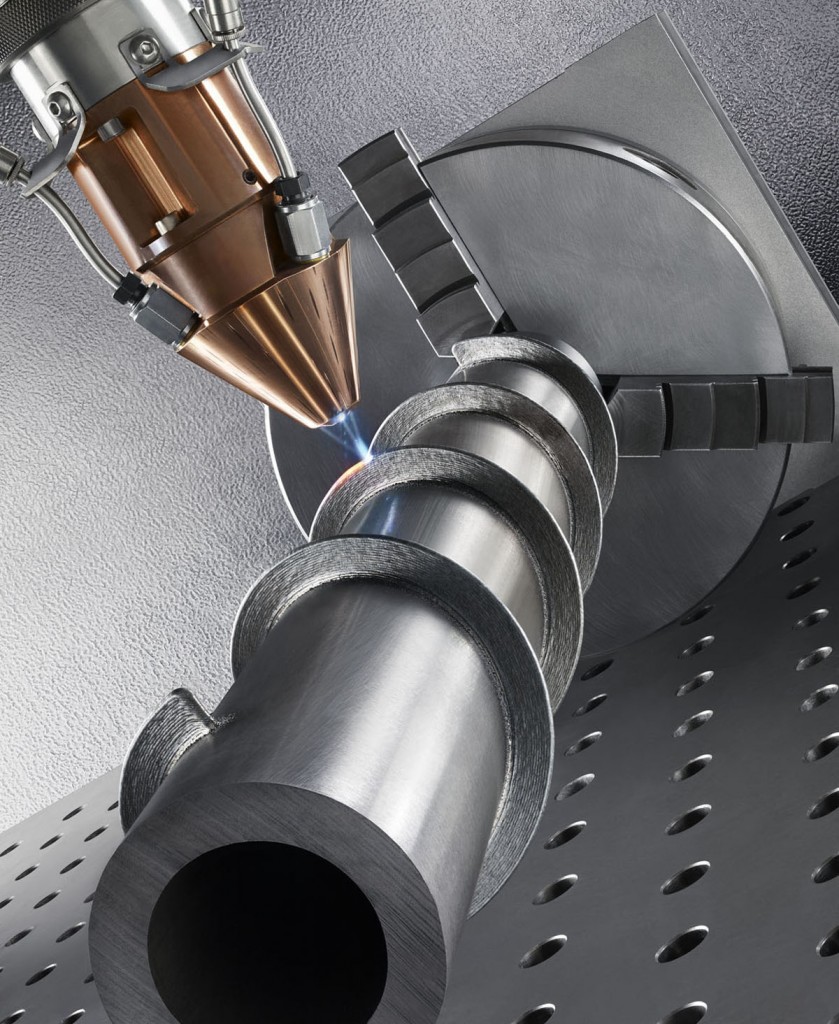

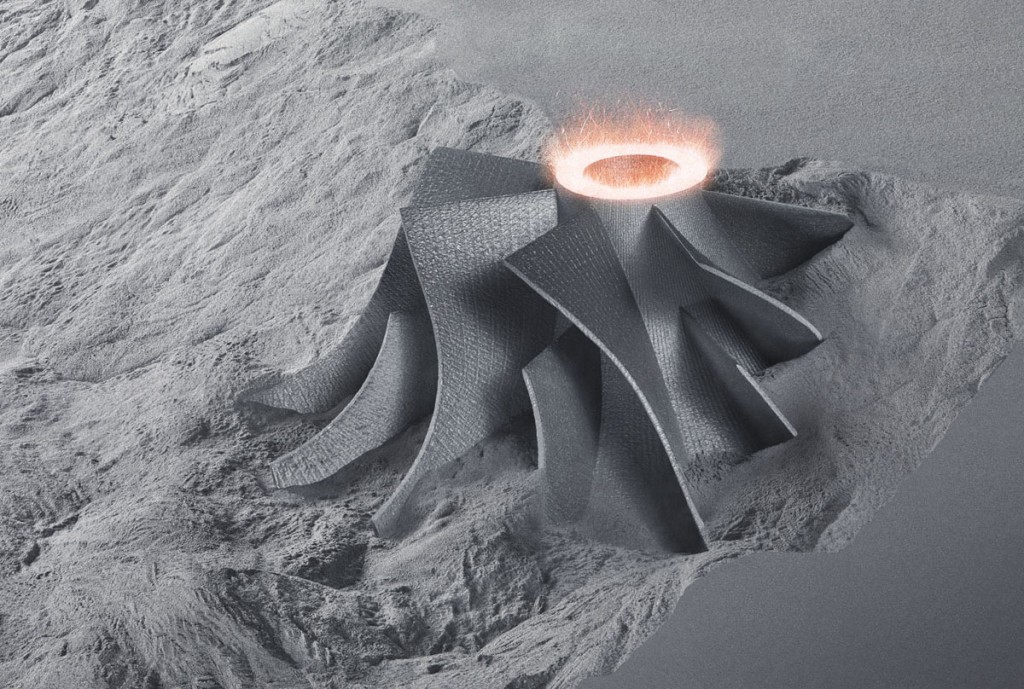

According to TRUMPF, the company will be displaying the new laser metal fusion (LMF) system at the event, from November 17-20. It will also present a new laser metal deposition (LMD) system, which was developed internally, making the German company the only one to be able to offer both leading metal AM technologies. Both systems originate from the efforts by the newly founded division at TRUMPF headquarters in Ditzingen. Head of TRUMPF Laser – und Systemtechnik GmbH, Dr.-Ing. E.h. Peter Leibinger, says of the new additions: “The introduction of these new 3D printers is an essential first step, since additive manufacturing will not only supplement production techniques in the future, but will also exert a formative influence on them. We will be offering rugged and highly productive machinery with which small and medium-sized parts incorporating complex structures can be manufactured.”

Though there are already a range of manufacturers of metal 3D printers on the market, the industry is still a small one and the addition of the TRUMPF-Sisma Joint Venture adds even more excitement to the field, by combining the German company’s huge size and experience with Sisma’s unique precision manufacturing deriving from its experience in the jewellery sector. This is clearly shown by LMD’s potential as a faster process which can be combined with other digital industrial manufacturing applications and SLM’s high precision and full geometrical freedom. There may not be a better time and way for TRUMPF to get seriously back into AM.

Leave A Comment