When it comes to 3D printing materials, nylon has been widely recognized as one of the most useful types of print material available. Yet one major drawback to using a nylon-based filament is the inability to easily glue pieces together due to its smooth texture, necessitating specialty nylon glues to get around the issue. When two major bonding companies stopped manufacturing this specialty adhesive, the material-making pioneers at taulman3D, one of the original inventors of specialty filaments for 3D desktop printers, decidedly took action and have just released the “ComPlete” Nylon glue.

Taulman3D has already left their prestigious mark on unique and specialized 3D printing materials, but decided to go outside of the filament market when they realized the distinct lack of bonding manufacturers there were making glue strong enough to hold together the naturally slippery base of nylon. That is how the taulman3D team ended up developing the ComPlete Nylon glue, a modified Cyanoacrylate adhesive that meets the maximum part=sealing standards set by the American Society for Testing and Materials (ASTM). The ComPlete Nylon glue accomplishes the difficult task of connecting 3D printed surface joints together, securing the ribbed 3D printed polymer surface evenly with minimal contact area.

Taulman3D has already left their prestigious mark on unique and specialized 3D printing materials, but decided to go outside of the filament market when they realized the distinct lack of bonding manufacturers there were making glue strong enough to hold together the naturally slippery base of nylon. That is how the taulman3D team ended up developing the ComPlete Nylon glue, a modified Cyanoacrylate adhesive that meets the maximum part=sealing standards set by the American Society for Testing and Materials (ASTM). The ComPlete Nylon glue accomplishes the difficult task of connecting 3D printed surface joints together, securing the ribbed 3D printed polymer surface evenly with minimal contact area.

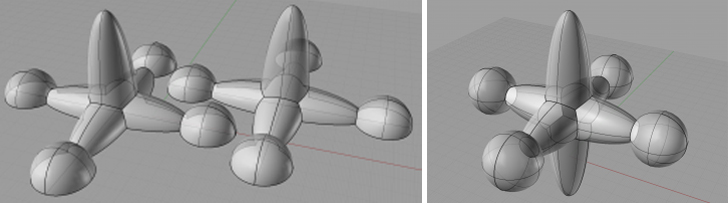

The team uses a ‘jack’, an essential part to the classic children’s game that goes by the same name, to showcase how their nylon glue will make 3D printing complex designs a more feasible operation. taulman3D explains that printing the ‘jack’ as one whole structure would take a considerably larger amount of support material and print time, but if the ‘jack’ were to split into two halves and 3D printed in parts, the aforementioned issues would be solved while ComPlete Nylon glue successfully connects the two nylon halves with one another. This breakthrough product will make it possible to print large-scale projects in nylon, piece by piece, finally allowing Makers to be more innovative with nylon printing materials.

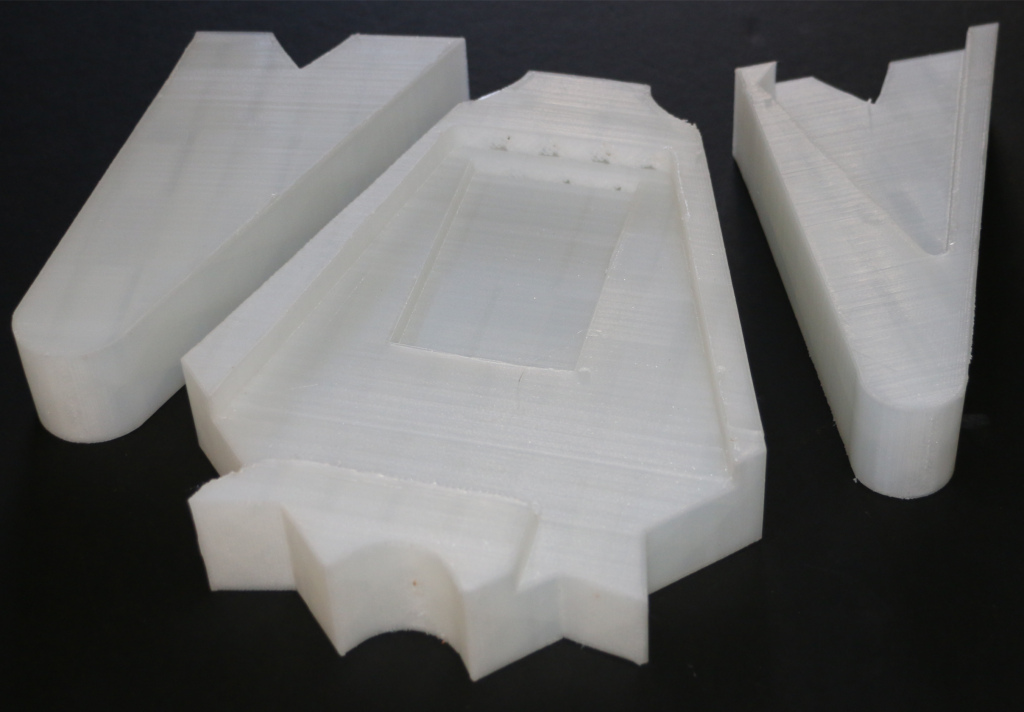

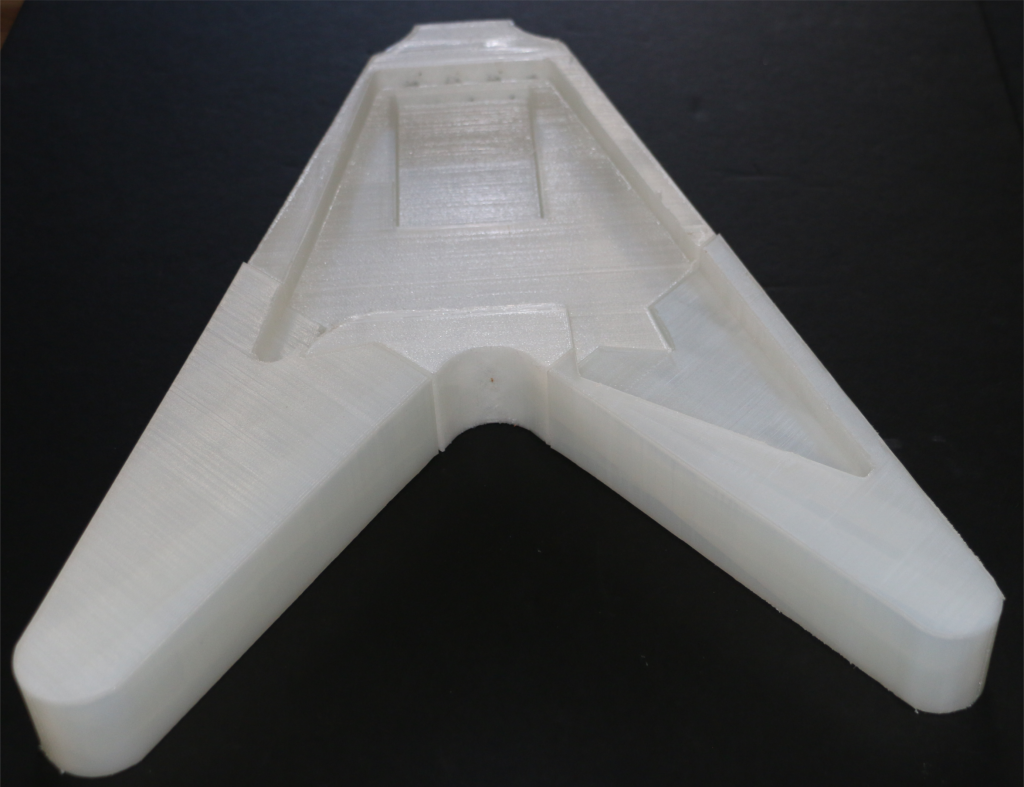

Nylon guitar body, pre glued and post glued

Nylon guitar body, pre glued and post gluedBefore taulman3D released their ComPlete Nylon glue, Makers had to go through the strenuous task of modifying their printed nylon with sandpaper or other types of abrasives, a process that is both time consuming and potentially detrimental to the strength of the material. The ComPlete glue is packaged in 20g bottles, and is equipped with a positive pressure cap to make the application onto nylon material clean and stress-free. “When “simple” becomes ‘out-of-control’ it’s time to find a different solution!” boasts the taulman3D team. And they have indeed found the solution! The ComPlete Nylon glue stands to greatly improve the way this slippery and widely used material can be printed and put together.

Leave A Comment