At 3D Print Week in New York, I was invited to interview Behzad Soltani, Vice President of Global E-Commerce and Business Development at Staples, Inc. Having written about the company multiple times, and as a consumer, I didn’t exactly anticipate any surprises coming from the office supplier, but, when I got to the Staples booth to speak with Behzad, I learned that Staples is actually up to a lot more in the 3D printing space than I previously thought.

Speaking with Behzad, along with Director of Corporate Communications Mark Cautela and Business Development Manager Sam Garzon, we began with some of the topics I was already aware of. On the retail front, Staples sells 3D printers and 3D printing supplies in-store and online. You can head over to their website and order a wide range of machines: the complete MakerBot line, various generations of 3D Systems’ Cube 3D printers, the Afinia H480, the BEETHEFIRST, the Leapfrog Creatr and Creatr XL, the Flashforge Creator, and the Matter & Form 3D scanner. Some of these are also available in physical Staples stores, with a number of them carrying MakerBot machines.

As we began discussing some of the company’s other initiatives outside of the US, I learned that Staples, as a global company, doesn’t enter various markets with a single-pronged approach. Behzad explained, “Our products and services are very localized. Certain brands have certain strengths. For instance, Staples Europe began with Mcor. The US is much more diverse, so Staples works with Stratasys and 3D Systems. We do this across the board. On the service side, there’s a wide variety of technologies out there. This goes for standard printing, as well, with Xerox, Canon, HP, and all of these companies. We want to bring all of these services to our customers.”

It was at this point that the overall Staples business model for 3D printing started to coalesce. Just as Staples offers multiple 2D printer brands, the office supplier isn’t about selling a single 3D printer or 3D printing service. In fact, they aren’t even solely an office supplier. Staples is a business-to-business solutions provider. So, in addition to office equipment, the company sells printing and design services, even business consultations. The owner of a small bakery might look to Staples to purchase some binders to organize wedding cake designs, order a few thousand flyers made, or speak to a consultant about re-designing their store’s signage. All of this, as someone who doesn’t own his own business, had not even occurred to me; I just go there to buy ink cartridges!

The same works at the other end of Staples’ 3D printing spectrum, with a customer wandering into a Staples looking for paper and coming across the shop’s Innovation Center, where a 3D printer might be chugging away. They could purchase the MakerBot on display or, speaking with a store representative, learn that the company also provides advanced 3D printing services and expertise.

It became clear to me that, for small businesses that already know the value of 3D printing, they might find a local 3D printing service provider to produce their goods, but, for those just becoming familiar with the technology, they might not know the benefits to begin with, let alone how to design with 3D printing’s benefits in mind. In so doing, they approach a knowledgeable business that can help them navigate the otherwise confusing world of this new technology.

Soltani elaborates, “They can come to us and we can give them the right technology. And that is one of the true values that I think we bring. They come into this space where there is so much innovation and want to leverage the technology, but it is constantly changing. So, in trying to keep up, upgrading machines, materials, and so on and so forth, we can bring that to them.” Furthermore, when a customer needs specific design and engineering services, that one might expect from an industrial design or service firm, Staples is able to provide that expertise through their partners, such as Stratasys Direct Manufacturing or 3D Systems’ Quickparts divisions.

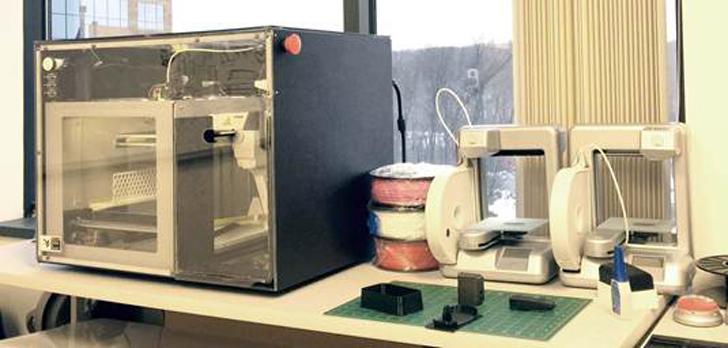

It was fascinating to learn that the company had infused itself into all aspects of 3D printing, from retail to providing services, to offering design expertise. Mark Cautela pointed out that the company even uses the technology in-house, when designing their own retail products. He explains, “The Staples Design + Innovation team is working on various projects and will launch 200+ skus during 2015. The projects range from fashion licensed to support our Style by Staples range, to new sensors that will be integrated into our Staples Connect home automation solution.” And, to prototype these products, the team uses the NVPro 3D printer from NVBOTS, which we’ve covered on 3DPI numerous times.

Though we’ve reported on the use of the NVBOTS device in schools, the printer is also sold in an commercial package that allows businesses to lease the NVPro. Mark further points how the printer is ideal for businesses such as theirs, “It has the capability to run 24/7, is cloud connected, has automated part removal and a print queue, and offers video monitoring so you can confirm it’s running and check the status of parts being printed. This allows the team the freedom to work on multiple projects and collaborate with their China-based counterparts, as the traditional wait time for 3D printed products is not conducive to a regular work schedule.”

This is only the beginning for the office supplier and service provider. As Staples gets into the 3D printing space more, the company has plans to expand their online offering. Just as you can walk into a Staples store, speak with a Print Pro and receive full end-to-end services, including design and 3D printing, customers will be able to have a similar experience online. This means that you’ll be able to upload a 3D file to the Staples site and have it printed, mirroring their 2D printing services.

Leaving the conversation, the aisles of Staples began to take on a whole new light to me. This wasn’t just a place where a customer might go to pick up office supplies, including a 3D printer. Staples, as a familiar face for designing logos and printing brochures, was becoming an interface for mainstream businesses to understand and utilize a revolutionary technology that might fundamentally change the way they operate.

Leave A Comment