People love to see robots at Maker Faires — they are certainly a crowd pleaser. And humanoid robots somehow seem to represent a future that is partly here, and partly still to come. The intersection of electronics, robotics and 3D printing present some exciting possibilities in the undiscovered future of manufacturing. From Jimmy, InMoov, Poppy (to name only a few) to the many electronics projects which utilize 3D printed components, we’ve only just begun to witness a synergy that has tremendous potential.

Giving demonstrations of his humanoid robot Robby at the World Maker Faire in New York recently, was Michael Overstreet (computer programmer by day, roboticist by night), whose mission is to reduce the overall price of building a robot by 3D printing as many parts as he possibly can, while making them accessible to all. The majority of 3D printers are used to prototype objects, and when designing robots with the intent of minimizing cost, time is just as important a currency as money. This speeds up evaluation processes and allows for key adjustments to be made to specific design decisions.

So how has Michael been spending his own time? For starters, he’s been busy as a key member of the Cowtown Computer Congress in Kansas City, Missouri. Michael is not only a power maker, he supports the makers at every level. Most recently, he was a big grassroots supporter of the Kansas City Maker Faire. It makes sense that he would want one in his hometown; after all he attends every single Maker Faire in America.

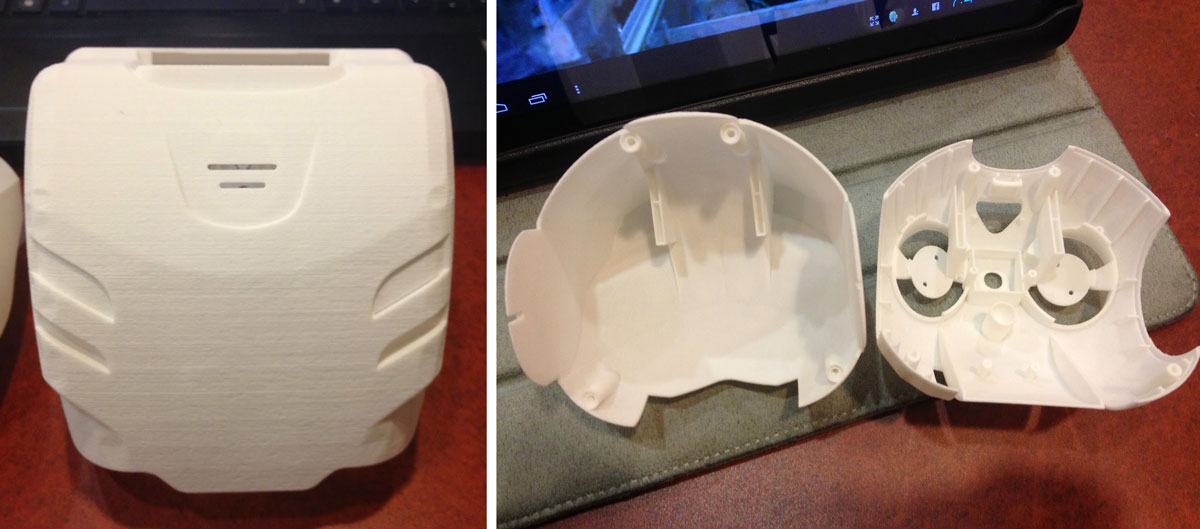

Michael is almost ready to release a production version of Robby, his Darwin-OP (Dynamic Anthropomorphic Robot with Intelligence – Open Platform) clone robot. Naturally, everyone was excited to see Robby’s child-like motion, and polite, with a voice reminiscent of Kit (William Daniels, not Justin Bieber) from the TV show Knight Rider. Printed in ABS from an UP Plus with nylon covers from Shapeways He’s got the cost of Robby down to $8000, but he’s far from finished.

Watch Robby in Action:

One of the most interesting things I learned about making the version of Robby I saw at the Maker Faire, is how Michael tried a wide variety of 3D printers and 3D printing services in order to create dozens of different parts. The first 3D printer Michael ever owned was the Makerbot Cupcake Mini, which proved unreliable, but allowed him to tinker and understand the potential applications of the technology. Upgrading a bit to create his first bracket, Michael utilized a UPrint Plus 3D printer.

In order to create the Darwin OP covers he chose to have them printed by Shapeways in strong and flexible nylon. Then he moved on to printing Robby’s head with a Sedgewick DLP (Digital Light Processing) printer. He plans to incorporate more and explore 3D printing parts in materials such as alumide, from I.Materialise’s SLS printers, and from resin using SLA printers. He also keeps costs down by designing his STL files on Autodesk 123.

Check out Michael’s excellent blog where he chronicles in great detail his process and what he hopes to accomplish in the near future.

Here’s an inspiring excerpt:

“After the robot is fully functional the next step will be redesigning its covers or modifying its covers for cosmetic or for functional reasons. Cosmetic ideas are to make it look like my favorite humanoid robot’s Robbie, Gort or C3-PO. I will leave the functional redesign to the imagination of the reader. What would you want a humanoid robot to do and what do you think it should look like? As I work on this robot and make it as good or better than the original, I have come to realize that I may never be fully done with this project or idea. I think the only limit to this project is my imagination. This, I think is the greatest benefit that we will get from the personal fabrication movement. I think it has opened up limitless possibilities for an individual to fully explore in solid form, their dreams, ideas and imagination.”

Leave A Comment