The world of plastics and polymers is wide and complex. There are tons of materials out there and only some of them can and have been optimized for use in 3D printing. So, if you were a company that produced some of the most advanced polymeric mixes out there, what would you do? You would probably do what Sweden based Nexam Chemicals just did for its PEPA Crosslinker: develop a process for using it for 3D printing with thermoplastics.

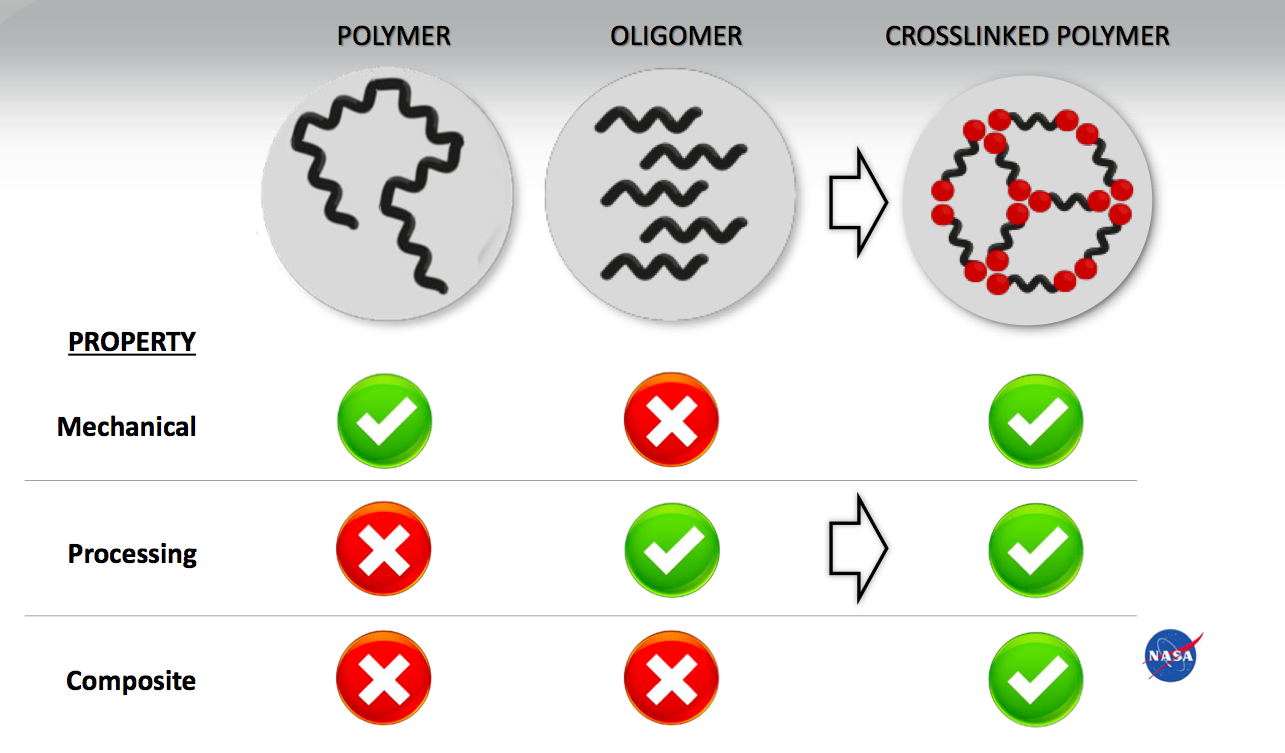

Nexam is known for developing technology and products that improve the properties of polymeric materials using conventional processing equipment (i.e. extruders). Its technology is used for cross linking polymers (which in principle can consist of an unlimited number of monomers) and oligomers (which consist of only a few monomers) to create new cross linked polymers with superior properties.

Controlled crosslinking can give the original polyamide enhanced properties in terms of chemical resistance and thermal/dimensional stability, make it stronger during use and make it more recyclable. It can also improve throughput and enable new processes.

According to the latest Chinese patent filed in China by the Institute of Chemistry at the Chinese Academy of Sciences, that is what the Crosslinker PEPA material (aka Neximid 100) will do, by enabling new methods and new capabilities for 3D printing of polyamide thermoplastics, giving nylon properties that in certain circumstances may allow it to be used to replace metal components.

Leave A Comment