AMFG, a 3D printing software company based in the UK, has announced it has secured £350 thousand in funding from Innovate UK to further the development of its AI and machine learning technology for additive manufacturing. As part of the project, AMFG will be working with key partners, including the University of Nottingham’s Centre for Additive Manufacturing (CfAM).

Speaking to a representative of AMFG, Industry learns more about this fund, and the company’s AI monitoring process.

Scalable end-part production

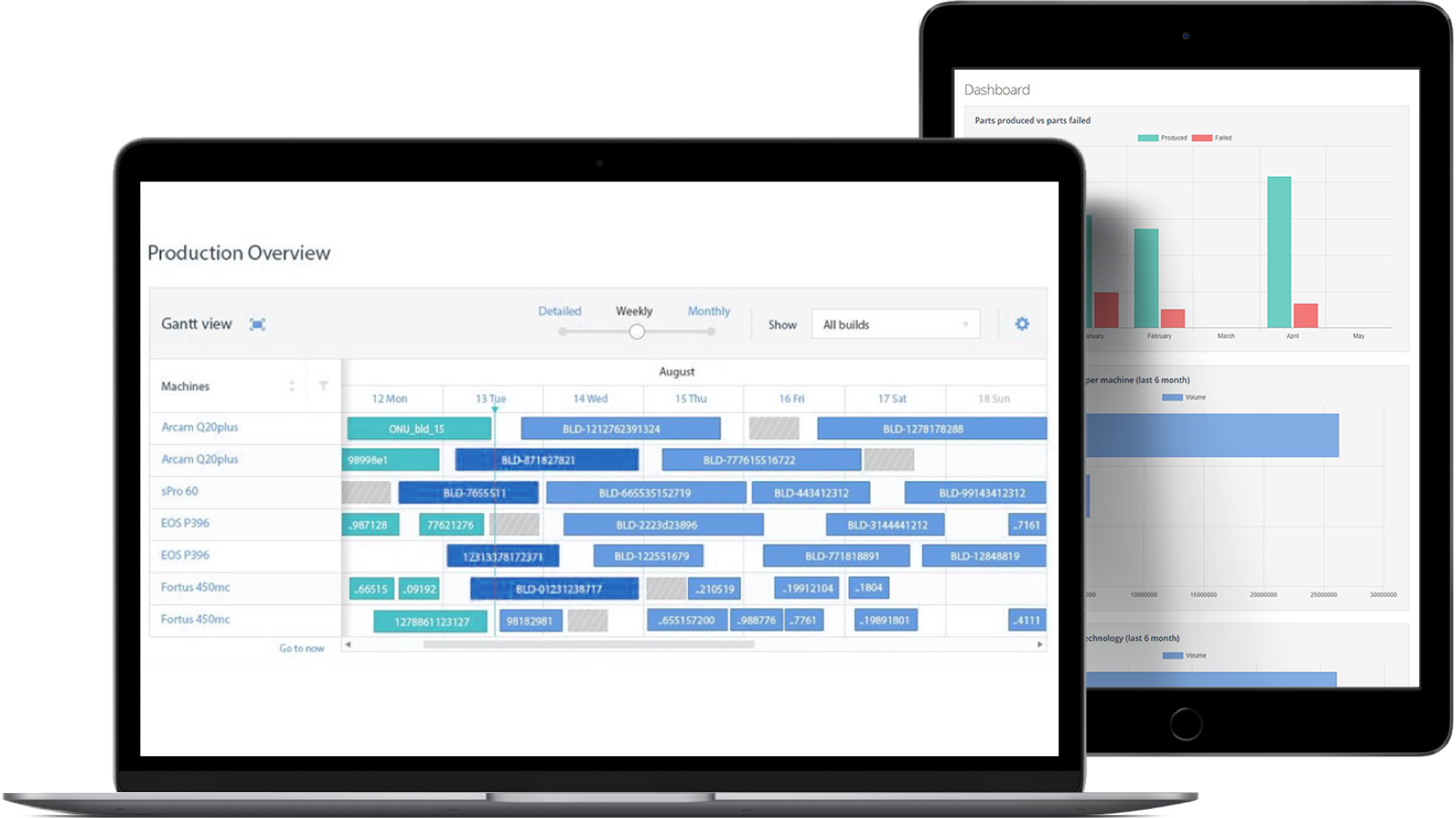

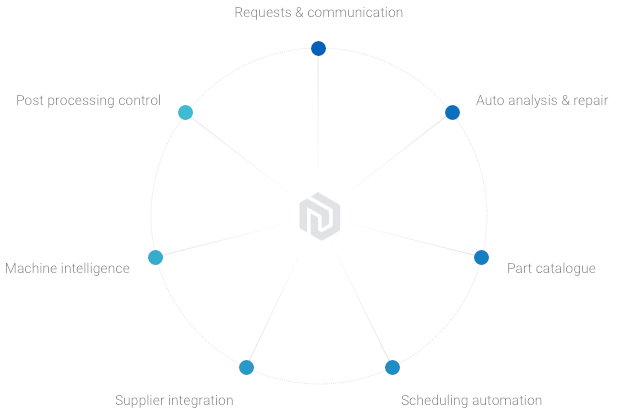

AMFG aims to make additive manufacturing more efficient by implementing machine learning technology. The funding provided by Innovate UK will therefore be used to build AMFG’s comprehensive workflow management/manufacturing execution system (MES) software, which was launched in 2018.

Detailing the process, the company representative tells us, “Firstly, with the AMFG platform, all planning steps will move from paper-based or different software solutions into one tool that covers the full production process digitally. Therefore, the planning status and changes are automatically tracked,”

“Furthermore,” they add, “the platform can connect to most industrial printers, any software, PLM or ERP solution and, if the sensors, scanner or cameras are IoT ready, they too can be connected.”

Quality concerns and lack of efficiency are barriers that AMFG believes are preventing additive manufacturing from being scaled for production. This project’s focus, then, is on improving quality assurance and optimizing scheduling for the fabrication of end-use parts. In particular, AMFG will develop methods to improve the analysis of parts during the quality assurance stage, including the use of wide-ranging data sets. It will also work to allow users to predict failures before they occur, by further developing its machine learning technology.

“Currently, additive manufacturing still needs to prove that end-part production is viable at scale,” said AMFG’s CEO, Keyvan Karimi in the funding press release, “Software will be a vital piece of this puzzle.”

Innovative UK funded automated additive manufacturing

Innovate UK is a non-departmental public body for accelerating innovation, and operates at the UK’s Technology Strategy Board. It funds business and research collaborations, and drives investment into research and development, across a number of areas including aerospace and biomedicine.

Another recent example of Innovate UK’s support is a grant of £960k to Valuechain.com. Also based in the UK, Valuechain.com makes a production management software for additive manufacturing called DNAm.

Giving further information as to the body’s funding for AMFG, our spokesperson explains, “Innovation is required to grow the UK’s manufacturing productivity, increase material efficiency and sustain our competitiveness in the long term […] Innovate UK’s aim with this initiative is to support the scale-up of innovation in manufacturing processes,”

“As per Innovate UK’s requirements, those activities should have already overcome the main technical risks and be at a maturity of Technology Readiness Level (TRL) 5 or higher, and/or at a Manufacturing Readiness Level (MRL) of 4 or higher.”

Further, the £350 thousand of funding will be delivered to AMFG on a milestone basis.

Working with Nottingham’s Centre for Additive Manufacturing

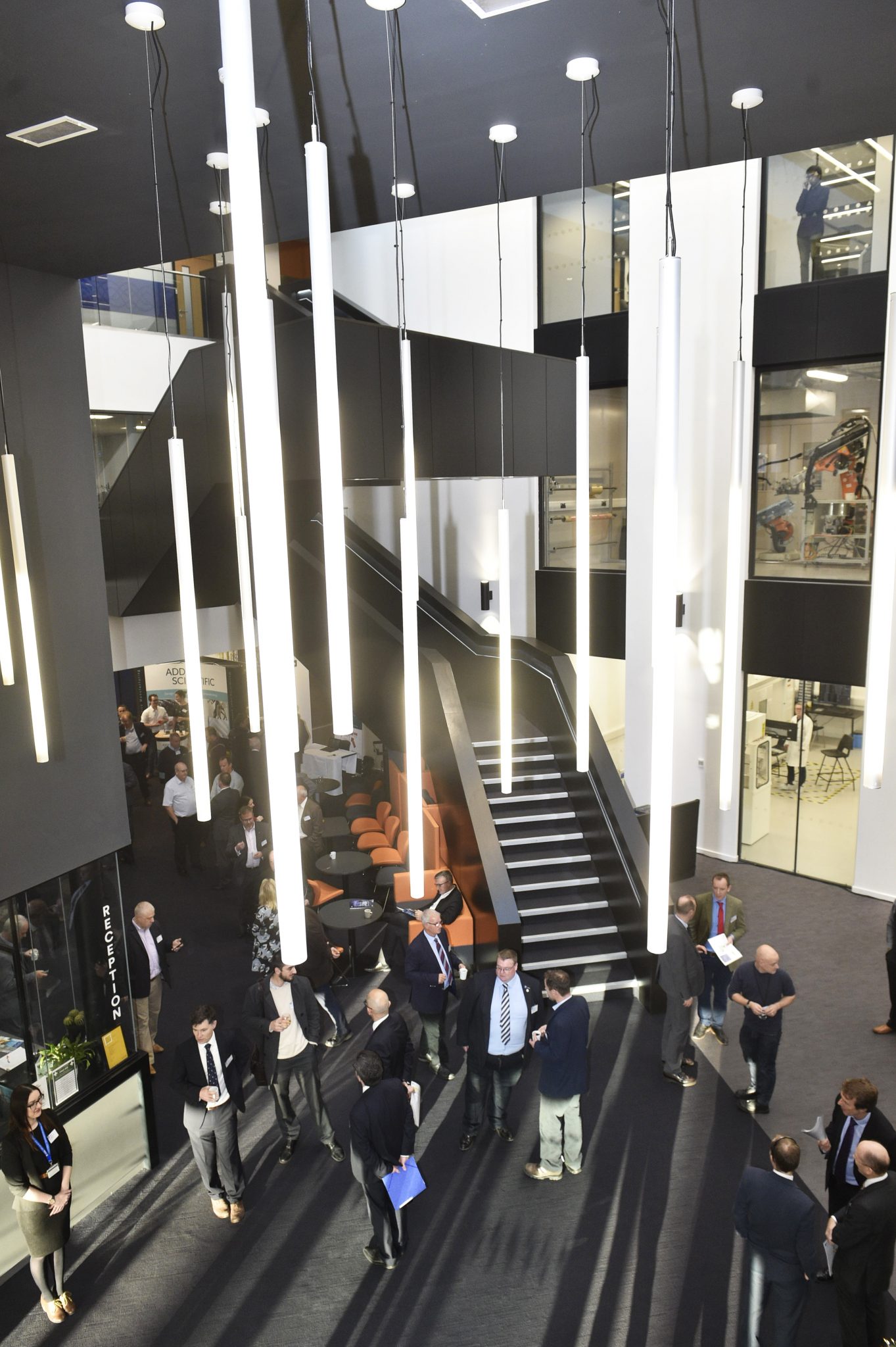

The CfAM, which will be helping AMFG develop its software, is located in the £24 million Advanced Manufacturing Building (AMB) at the University of Nottingham. CfAM’s involvement in the project comes after the AMB was opened by Siemens UK CEO, Juergen Maier in December 2018. A hotbed of innovation, the University of Nottingham has also engaged in several other additive manufacturing project in recent years, including a previous collaboration with University College London (UCL) to improve human brain mapping with a 3D printed magnetoencephalography (MEG) helmet.

“The Centre [for AM] is one of the leading research groups in the field of AM technology across the globe and is conducting research to advance the productivity, scalability and industrial adoptability of the technology,” said Dr Martin Baumers of the CfAM.

“AM technology is currently at a stage where it needs to demonstrate its stability and controllability in real manufacturing environments. Innovative software approaches will be central in achieving this.”

Karimi, CEO of AMFG, concludes, “We’re thrilled to put Innovate UK’s funding towards further enhancing our machine learning technology and helping manufacturers manage — and scale — their AM operations effectively.”

Make your nominations now for the Industry Awards 2019. Voting opens in March 2019. For more news about the latest Industry developments subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Looking for a career in additive manufacturing? Visit Jobs.

Featured image shows AMFG Workflow automation software for additive manufacturing. Image via AMFG.

Leave A Comment