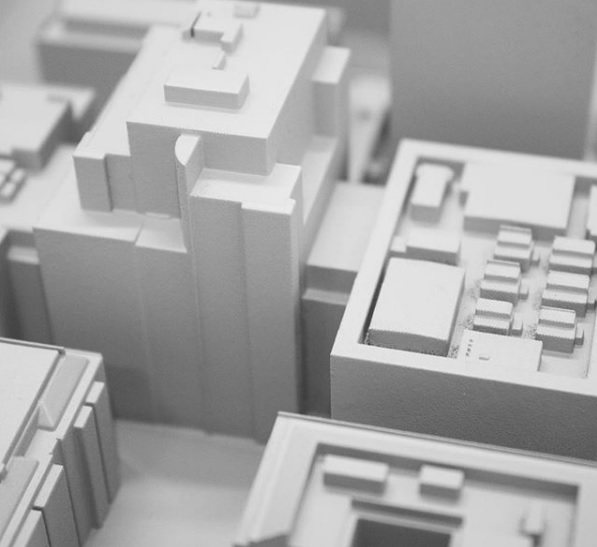

Michelle Greeff, the founder of Hobs 3D, a UK-based 3D printing service bureau, has launched Fixie, a 24/7 3D printing service for built environment professionals.

Located in London, Fixie has been established to streamline the preparation of files for 3D printing, encouraging the adoption of additive manufacturing in the architecture, engineering, and construction (AEC) sector.

“Clients probably don’t realize that the fixing of design files for 3D printing can be the most time consuming and costly part of the 3D printing process – it’s a manual process with a proportionally large labor cost,” said Greeff. “Through our new file fixing system, we’re creating a service that matches the potential of the technologies used.”

File fixing with Fixie

According to Greeff, fixing files for 3D printing can often account for over 50% of the cost of 3D printed building models. Such models have proven useful in both toymaking and industrial architecture as it allows designers to realize scaled physical iterations of their ideas rather than just computer visualization.

However, architects may not have experience in 3D printing technologies needed to translate their designs into 3D printed models. Fixie offers the Upload and Briefing and Project Tracking tools on its 24/7 online platform to move such projects forward.

The Upload and Briefing tool generates quotes as well as consultation on the most relevant additive manufacturing processes for a building model. This includes Selective Laser Sintering (SLS), ColorJet printing, Stereolithography (SLA) and hand-finishing post-processing. Once satisfied, the company’s 24/7 file fixing service transforms the given digital designs into an optimized 3D printed model.

Fixie is developing the Project and Tracking tool, set to be released April 2019, which will allow live progress reviews of building models. These features, the company believes, will ultimately accelerate architectural projects across the UK. Greeff added, “File fixing for architecture is a highly bespoke, project by project process. We want to support 3D bureaus, as well as in-house model making and rapid prototyping teams to increase their capacity to take on projects and ultimately the volume of work that they produce.”

Vote now to decide this year’s winners of the 2019 Industry Awards.

For all of the latest additive manufacturing news and updates, subscribe to the Industry newsletter, follow us on Twitter and like us on Facebook.

Featured image shows a 3D printed architectural model. Photo via Fixie.

Leave A Comment