General Lattice is developing a predictive modeling toolset to design and generate lattice materials based on real-world data, which will improve impact absorption technology for the US Army next-gen combat helmet. The yearlong research and development project is currently underway at General Lattice’s facility in Chicago, Illinois.

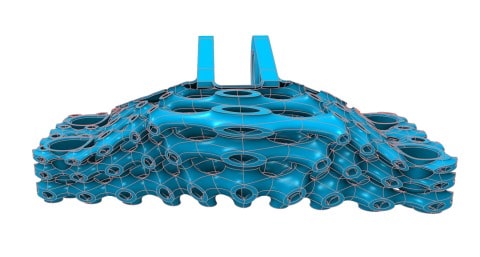

The capabilities of traditional foam material have been exhausted, and General Lattice is engineering and authenticating its replacement using 3D printing and advanced lattice geometries. The state-of-the-art lattice materials designed by the company are unattainable through conventional composites and manufacturing technologies. These generated lattice materials will interact with real-world environment testing to accurately validate key performance requirements as defined by the Development Command Soldier Center (DEVCOM-SC). This is to enhance soldier protection and survivability for the US Army warfighter.

Manufacturing on Demand

General Lattice has selected specimen attributes, material, and hardware candidates applicable for the next-gen combat helmet’s suspension system and impact absorption. Manufactured lattice samples will be tested to measure the accuracy of General Lattice’s predictive model. The predictive toolset will be the primary result of the contract, allowing DEVCOM-SC to effectively explore lattice padding profiles for future use across myriad applications.

General Lattice has selected specimen attributes, material, and hardware candidates applicable for the next-gen combat helmet’s suspension system and impact absorption. Manufactured lattice samples will be tested to measure the accuracy of General Lattice’s predictive model. The predictive toolset will be the primary result of the contract, allowing DEVCOM-SC to effectively explore lattice padding profiles for future use across myriad applications.

Lattice materials will revolutionize the way companies manufacture new innovative products across all commercial, industrial, and military markets. Utilizing advanced lattice materials and 3D printing enables General Lattice to engineer and manufacture true, personalized products that are fine-tuned to specific biometric characteristics without the additional costs and waste traditionally tied to customization efforts. This is possible through the Company’s expertise in computational design and digital manufacturing.

General Lattice is partnering with All Points Logistics LLC, an engineering, software development, and technology firm that has provided high-value services and solutions to the military and Federal markets for over 20 years. Further, General Lattice will collaborate with GoProto, a rapid manufacturing company based in San Diego, California.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment