Companies such as GE have invested heavily in utilizing metal 3D printing for industrial applications, creating prototypes and even end parts for jet engines. Still, the expensive nature of these industrial metal 3D printers, along with the lack of material capabilities thus far, has kept metal 3D printers a step behind some of 3D printings more accessible applications. To broaden the available palette of metal materials for industrial 3D printing, French Tech start-up Z3DLAB, a team made up of metal additive manufacturing specialists, has developed a metal-based 3D printable material composed of a mixture of Titanium and Zirconia.

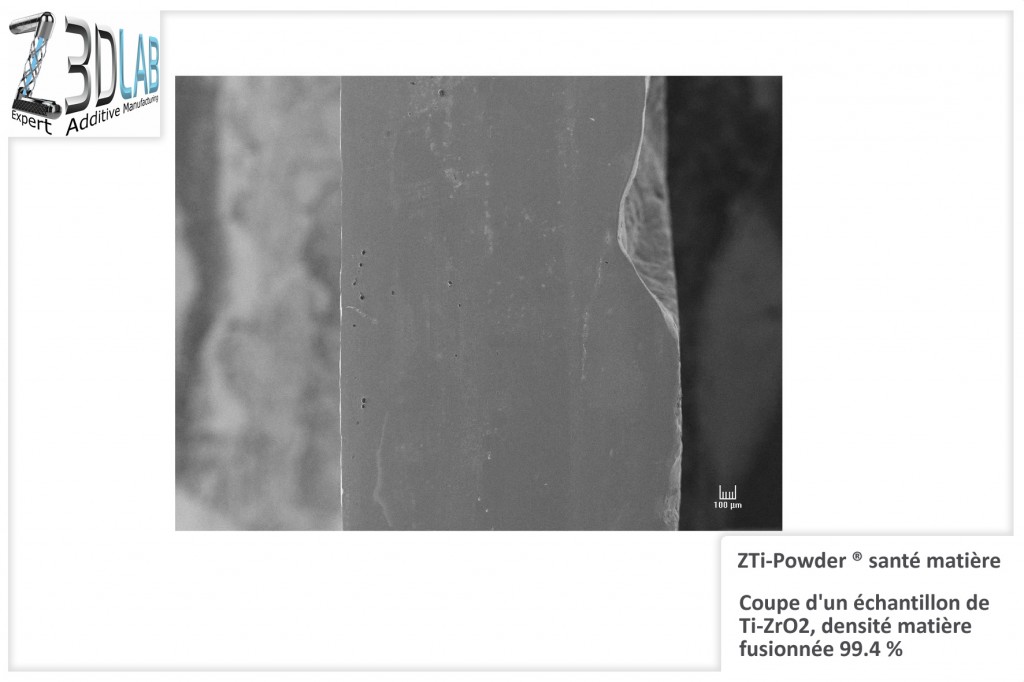

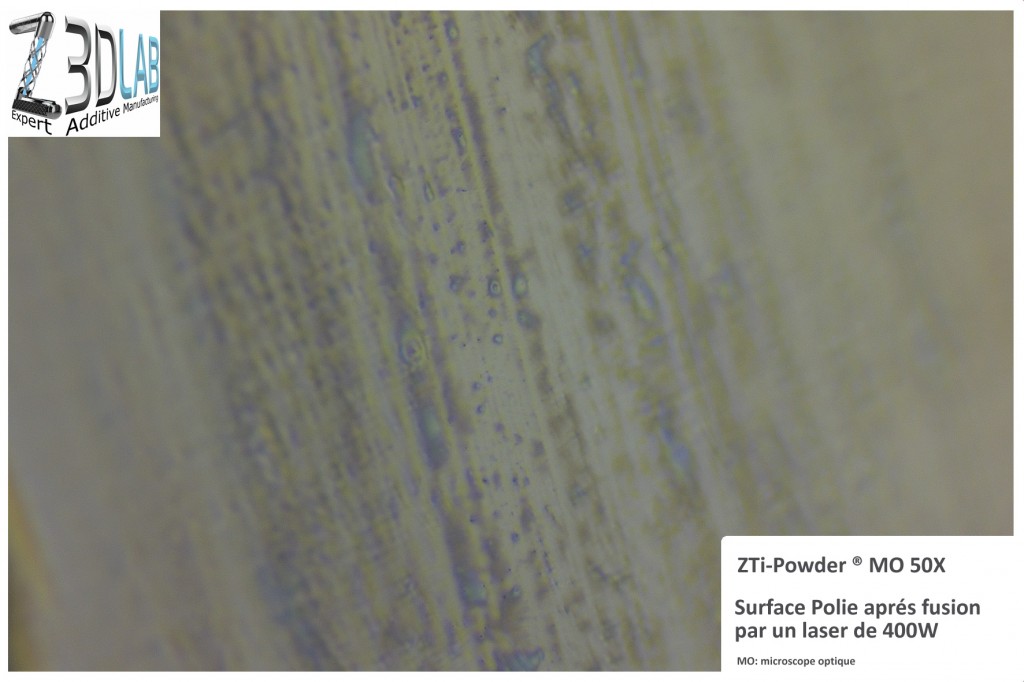

The final outcome of this material mixture is the ZTi-Powder, a titanium-ceramic combination created for selective laser melting (SLM). The malleability of Titanium mixed with the hardened nature of Zirconia makes for a lightweight, yet tough, metal-based powder able to withstand over 1000 degrees Celsius of heat. The two elements are extremely complementary to one another, not only because they contain similar natural expansion properties, but also in part because each of the materials covers the weaknesses of the other. The Titanium is known for its tough physicality, but deteriorates quickly due to low abrasion resistance, while Zirconium’s strongest suit is the ability to resist this type of wear and tear, yet lacks where Titanium reigns in tenacity.

The Z3DLAB team decided to implement layers of Zirconium into the surface of their Titanium-based composite once it was discovered that allergy-causing Aluminum and Vanadium ions were being released with the deterioration of Titanium alloy, which takes place within oxygen-lacking areas, such as dental and bone implants. The combination of the two materials has helped to mask the flawed properties of Titanium and Zirconium, allowing for much more flexibility and opportunity when it comes to metal 3D printing.

The high-quality powdered material mixture has a lot of potential for applications within industries such as medical, dental, aeronautics, and automotive. In the following year, after Z3DLAB premieres their ZTi-Powder to the world, they hope to develop their innovative material even further with additional fundraising. By combining a flexible metal with a sturdy ceramic, Z3DLAB is redesigning a classic idiom with their impact on metal 3D printing, proving that sometimes, two materials are just better than one.

Leave A Comment