A document submitted to the U.S. Securities and Exchange Commission (SEC) confirms that Formlabs, provider of the Form 2 and Fuse 1 3D printers, has raised a further $30 million in series C funding.

Funding history of Formlabs

Formlabs was founded in 2011 with $1.8 million in seed funding from accelerator VC SOSV. Its first SLA 3D printer, the Form 1, was launched via Kickstarter raising a recording breaking $2.9 million in backing.

DFJ Growth led Formlabs’ Series A funding in October 2013 preceding the launch of the Form 1+ which replaced the original Form 1.

The new flagship SLA 3D printer, the Form 2, was released in September 2015, and the next round of funding was announced in August 2016. In Series B, Formlabs raised $35 million from 7 investors including the Foundry Group, and Carl Bass, former CEO and current board member at Autodesk who is also an independent director of Formlabs.

Full details about the investors involved in Series C have yet to be confirmed by Formlabs, but Industry is in conversation with the company and will report on any further news as it arises.

Form, Fuse and Cell

The latest releases planned by Formlabs are the Fuse 1 and Form Cell automation platform.

The Fuse 1 is the company’s first foray into selective laser sintering (SLS) technology, and has been in development since 2015, around the time of the Form 2 launch.

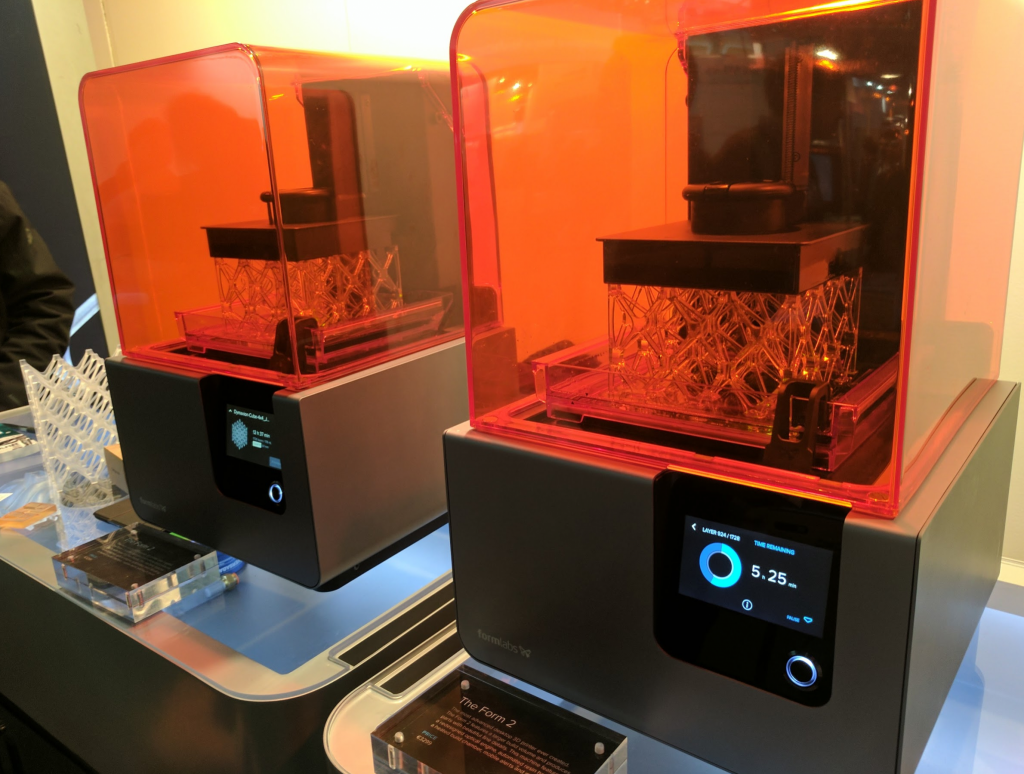

The Form Cell is the company’s solution for scaleable 3D printed production. An enclosure containing five Form 2 3D printers and a Form Wash and Form Cure module is managed by moving a robotic gantry, enabling continuous, 24 hour operation.

Formlabs also has a sneaker production partnership under its belt with MA-based footwear manufacturer New Balance. Products of this partnership will be made using the Form 2 3D printer.

3D printing for series production

Further details of the New Balance partnership should be released throughout 2018, and the Form Cell platform is expected to start shipping in the first half of the year.

Through each of these releases though, one thing is clear: Formlabs is in pursuit of 3D printing for small-batch, end-use production. The future of 3D printing goes beyond prototyping.

For more of the latest trends in additive manufacturing for end-use production, visit our interview series on the topic featuring comment from Daimler AG, Big Rep, EOS and Autodesk.

Sign up to the Industry newsletter, follow us on Twitter, and like us on Facebook to be the first with all the latest news and exclusive reports.

Join 3D printing jobs to take your career and recruitment to the next level.

Vote for your technologies and innovations of the year in the 2018 Industry Awards here.

Featured image shows the Form Cell configuration. Photo via Formlabs

Leave A Comment