FIT AG, a German additive manufacturing specialist, has made a substantial investment in bringing 3D printing to production.

With facilities in Germany located in Lupburg, Postbauer-Heng, Feldkirchen and Eching, as well as internationally in Kronstadt / Brasov (Romania), Nagoya (Japan) and Boston, MA. FIT AG employs over 330 people.

The additive manufacturing specialist has now purchased five EOS M 400-4 systems. The machines will be used to create an industrial 3D printing factory geared towards serial production.

EOS are already leading in the integration of additive manufacturing as a core component of the smart factory of the future – one example is the Airbus Aerospace Factory in Munich. The new deal will see EOS act as a strategic partner with FIT AG as the metal 3D printers are brought into service to provide components for the automotive, medical technology and aerospace sectors.

High productivity additive manufacturing systems

The EOS M400-4 metal additive manufacturing system has a build volume of 400 x 400 x 400 mm and is powered by four lasers.

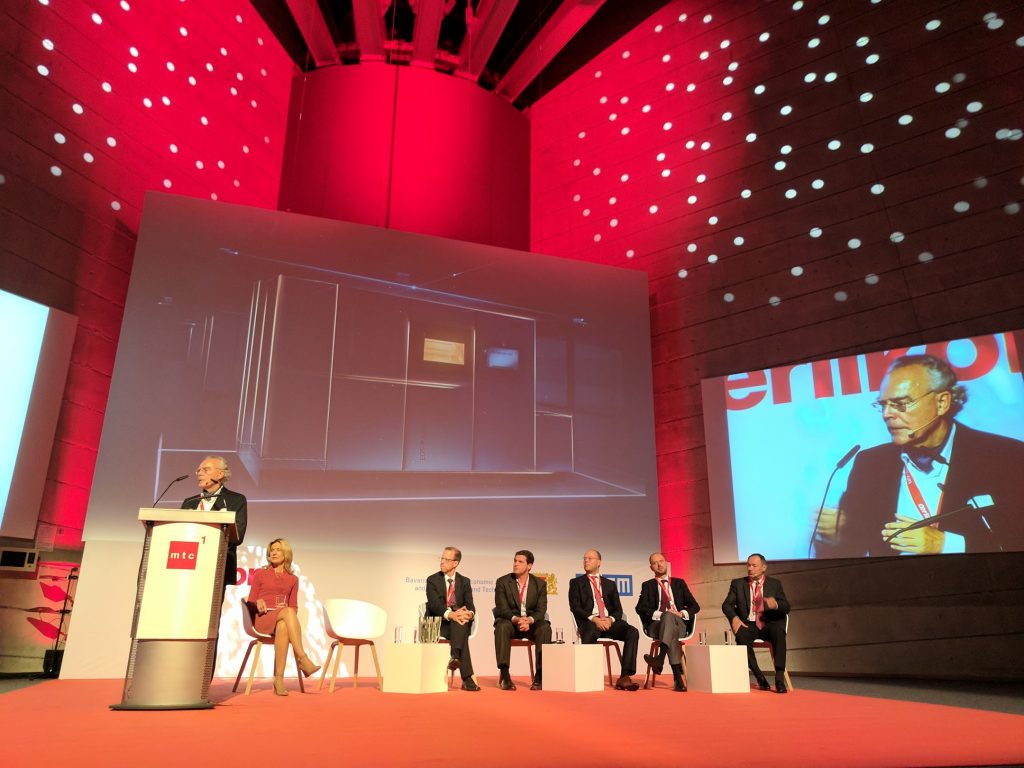

Earlier this week, in Munich I heard more from EOS founder, Dr. Hans Langer about how his company is set to further expand the throughput of EOS 3D printers. One aspect EOS is increasing the number of lasers in their systems, Dr. Langer says a high productivity additive manufacturing platform with ten lasers is in development.

The another element of moving to production is increasing build volume. Industry has already seen several previews of the EOS next generation polymer additive manufacturing system set to be launched at next month’s formnext event in Frankfurt.

Speaking about the latest investment by FIT AG, CEO Carl Fruth said, “The new generation of EOS systems not only convinced us with the outstanding quality of the components it produces, but above all with its open interfaces, which allow us to seamlessly integrate these machines in our quality assurance concepts – a further big step towards achieving the industrial-scale additive manufacturing of components.”

“It is our declared objective to supply our customers with components of exceptional quality from one single source. We intend to achieve this objective as we move forward with EOS as a dependable partner and long-term supplier.”

Dr. Adrian Keppler, CEO of EOS GmbH, continued “I am delighted that over 20 years of successful collaboration between EOS and FIT AG in the field of additive manufacturing of polymer parts are now being extended to include metal components. Carl Fruth of FIT AG is one of the most experienced pioneers in 3D printing manufacturing. We are therefore proud that he has placed his trust in EOS when it comes to establishing his AM factories. The investment in five EOS M 400-4 systems shows that our solutions are ideally suitable for an integrated large-scale AM production scenario.”

For more 3D printing insights and analysis, subscribe to our free newsletter and follow our active social media accounts.

Featured image shows some of the equipment available at FIT AG’s facilities. Photo via FIT AG.

Leave A Comment