Leading industrial 3D printer OEM and service provider EOS is celebrating its 30th anniversary. With approximately 3,500 systems installed around the world, the German company is holding onto its original mission statement from founder Hans Langer in 1989 which is:

“Shaping the future of manufacturing.”

“The establishment of complete digital production platforms is a major goal that we are aiming to achieve in the coming years,” comments Adrian Keppler, EOS CEO.

“It’s not just about providing the right 3D printing solutions, but about evaluating, planning, setting-up, and optimizing AM production cells to leverage all the advantages and possibilities of digitalization.”

Success for EOS

EOS attributes its longevity within the burgeoning 3D printing industry to its exclusive focus on laser sintering, and the technology’s abilities to processing polymers and metals from an early stage, as well as custom materials. According to the company, powder-bed based processes are well suited to the rapidly growing market of series applications.

In 2015, EOS founded its consultancy unit Additive Minds. This business has so-far enabled over 300 successful customer projects and gained more than 100 experts worldwide. According to EOS support from Additive Minds has also accelerated the adoption of additive manufacturing. In one example case, in 2018 Canadian advanced manufacturing service bureau Precision ADM, completed a Validation Master Plan for additive manufacturing in line with M290 3D printers with the help of Additive Minds.

A million laser solutions

Currently, EOS has approximately 1,200 employees worldwide after starting out with a team consisting of just 4 people. In a previous interview with Industry, Dr. Langer explained, “The first years [of EOS] were devoted to materials development.”

“In 2007 we began to understand and see that with DMLS we could achieve completely new material properties. Based on powder-based metal materials, parts could be created using our manufacturing process that showed material properties much better than those which normally can be achieved with conventional manufacturing processes.”

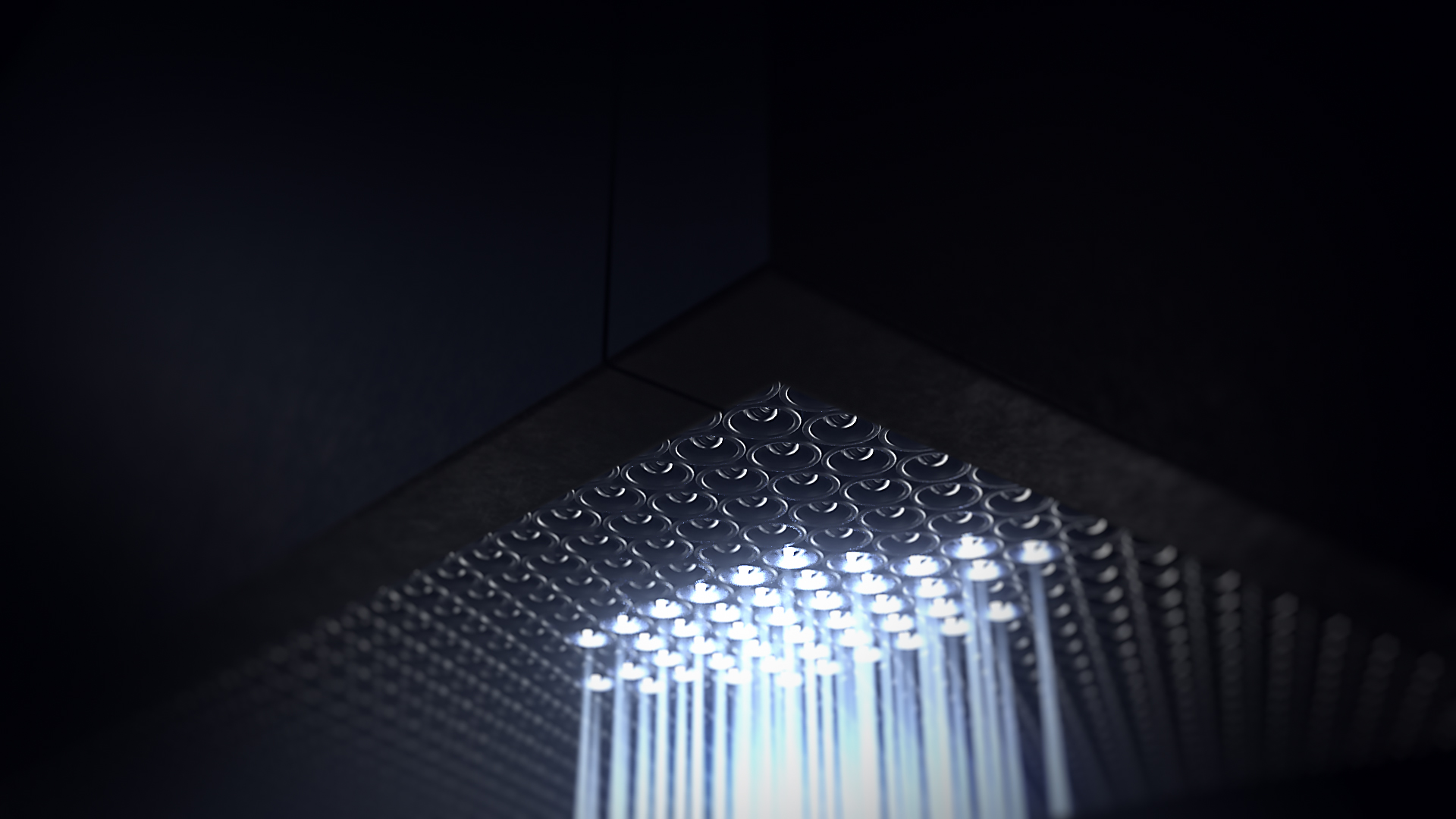

Looking to the future, EOS has welcomed advanced industrial 3D printing solutions such as the “million laser” LaserProFusion, technology. This method is designed for producing complex, serialized, strong and lightweight components in a matter of seconds per piece.

Vote for EOS as OEM of the year (Enterprise) for the 2019 Industry Awards.

For the latest automotive additive manufacturing news, subscribe to our 3D printing newsletter and follow us Facebook and Twitter.

Visit our Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows a polymer 3D printed part within the powder bed. Photo via EOS

Leave A Comment