EOS has entered an exclusive partnership with Hyperganic, a company that aims to accelerate innovation in engineering through its software platform that creates parts, structures, and entire machines through computer algorithms and AI, to advance the field of space propulsion.

“As a constant and pioneering innovator, we are now partnering with Hyperganic to introduce another paradigm shift in AM. It is a design shift that expands solution spaces as well as performance levels. At the same time, it will revolutionize the design process for AM, making AM a truly digital workflow from software-generated Algorithmic Engineering to digital manufacturing,” said Dr. Hans J. Langer, founder of EOS.

“We are very excited to partner with EOS in this industry-first collaboration. Algorithmic Engineering translates ideas into designs in minutes, with the engineer setting the rules and the computer generating the results. Specifically, the field of space propulsion which still uses very conservative designs, will benefit greatly from Algorithmic Engineering,” said Lin Kayser, CEO of Hyperganic.

Manufacturing on Demand

For centuries, humans have used drawing boards to translate ideas onto paper before CAD systems changed the game. Yet, even small design changes still require laborious remodeling work. Since every iteration costs time and money, CAD-based approaches compel engineers to design conservatively instead of pushing the limits. At the same time, freedom of design has always been one of the guiding principles of AM, enabling part structures and applications that were impossible to manufacture using traditional production processes. The partnership between EOS and Hyperganic now takes this approach to the next level.

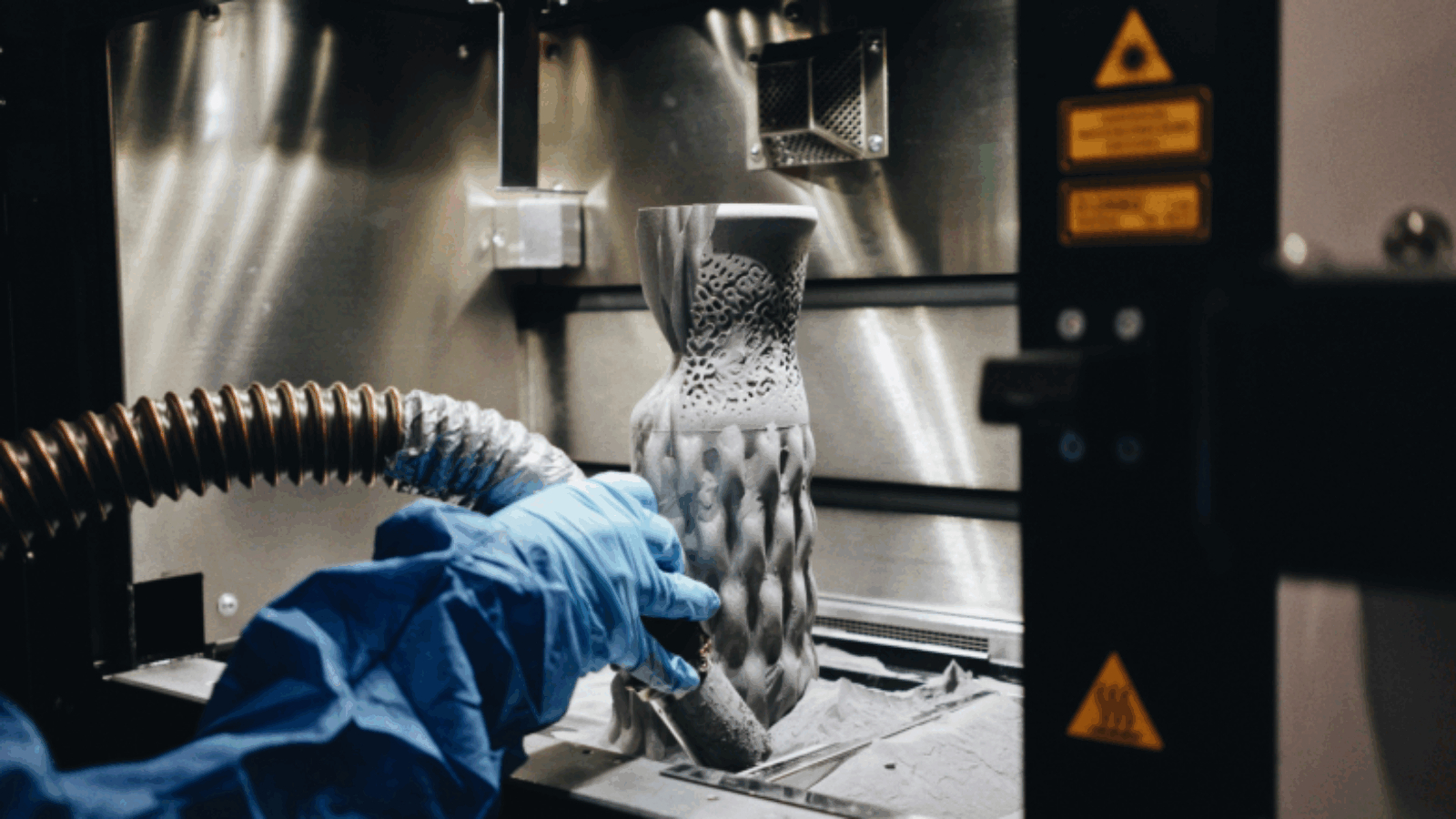

A radical example is the aerospike rocket engine designed by Hyperganic and manufactured by EOS and AMCM, an EOS GROUP company. The aerospike engine, classically considered a tremendous engineering and manufacturing challenge, was built from the ground up using an algorithmic model by Hyperganic. In just days, one of the hundreds of designs produced by Hyperganic was printed on EOS M 400-4. The highly complex part was printed with zero support using the newly developed EOS NickelAlloy IN718 process.

Consequently, the aerospike engine was automatically reengineered for production on a substantially larger AMCM M 4K system from AMCM in EOS CopperAlloy CuCrZr. The combination of this level of design complexity with the capability to print in this size reliably, will drive the next innovations in space propulsion.

You might also like:

AddUp Solutions and Uniformity Labs to collaborate: The partnership’s goal is to jointly market Uniformity Ti64 Grade 23 as an advanced material option on the FormUp350 to the combined customer base of AddUp and Uniformity.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment