Two weeks ago, HP officially entered the 3D printing industry, unveiling its proprietary Multi Jet Fusion 3D printing system. In its press conference extravaganza, the company made a number of bold statements about its technology, specifically that MJF was capable of producing stronger and more detailed, full-color parts at a faster rate and at a lower cost than other 3D printing systems. In the calm that now follows the HP storm, reflective minds like those at Econolyst have begun to dissect the bold announcement by the 2D turned 3D printer manufacturer. The industry-leading consultancy and analysis firm has examined HP’s press video and, with “cost modelling tools, technology data sets and even reverse engineering”, Econolyst has compared HP’s MJF 3D printing to other already existing industrial processes, creating a colorful infographic in the process (excerpts included in this post).

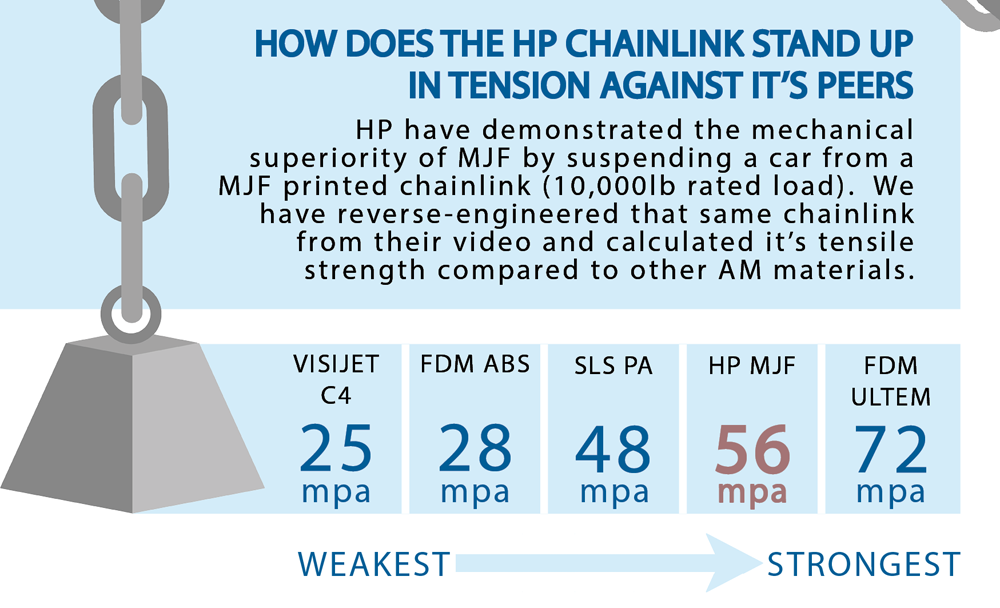

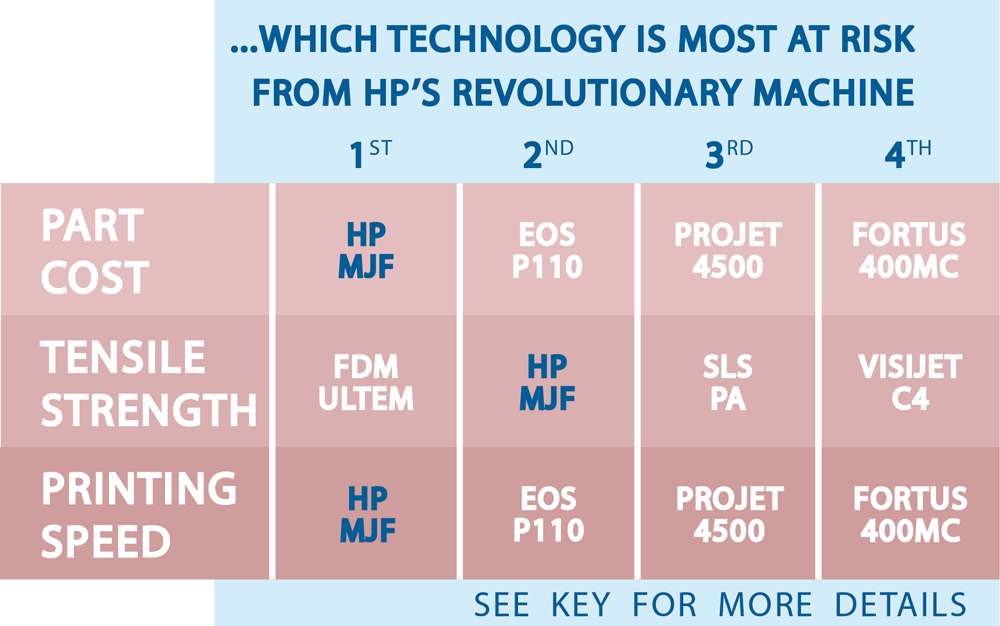

In their press conference, HP demonstrated the strength of their technology by 3D printing a chainlink capable of holding up a 10,000 lb load. They also boasted their printing process to be 10x faster than the fastest 3D printing process and “lower cost than any other in its class.” To better understand the MJF technology, Econolyst reverse-engineered the chain link’s tensile strength, determining it to be 56 mpa, compared to the 72mpa of Stratasys’ Ultem material for FDM printing. They then compared the print time of the MJF process to other systems in their database. The time it took to print the chainlink, a reported thirty minutes, was significantly faster than its competitors, beating the EOS P110 by five times and ProJet 4500 by eight times, just shy of the 10x mark listed by HP.

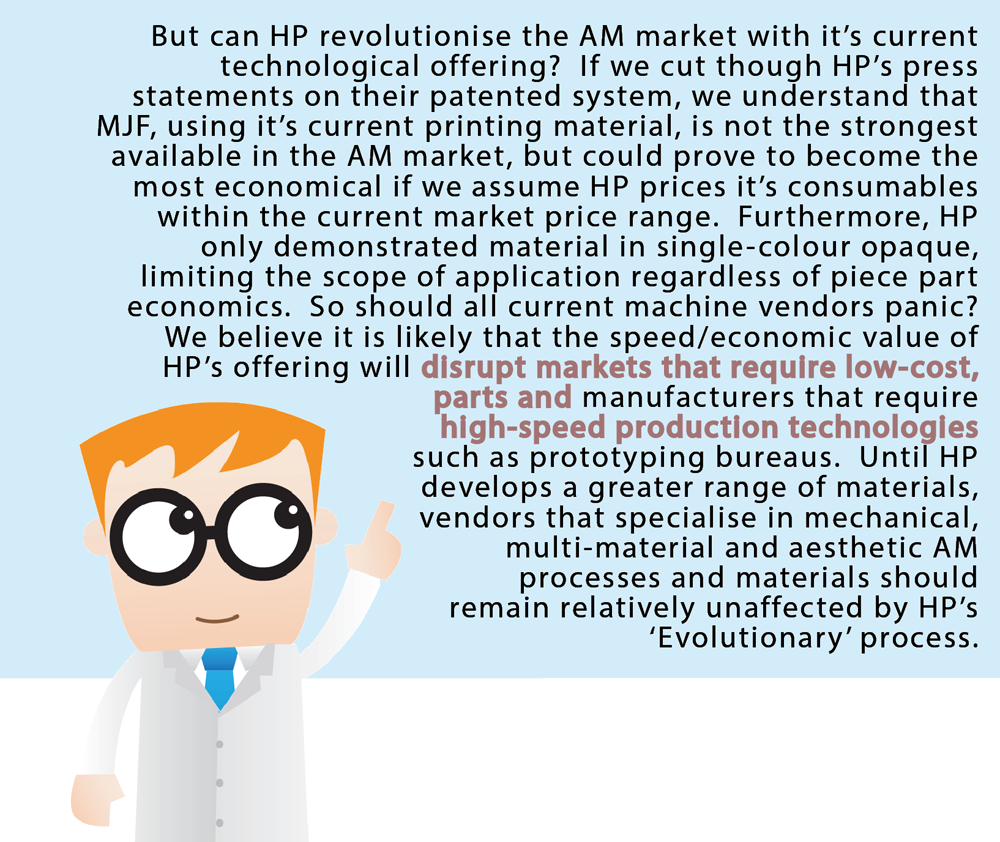

The firm then broke down the potential cost of the MJF process, comparing the potential cost of the machine to the cost of its consumables – a powder and jetting agent – and matching it against other technologies that could be considered in the same “class” as HP’s own. Econolyst determines that, in order to truly bring cost savings to the industry, MJF will need to use less costly consumables than its competitors, regardless of the cost of the machine. In so doing, the firm believes that HP could bring significant competition to even “the highest machine class” and that HP could disrupt the 3D printing game as it stands. Econolyst adds that the biggest threat HP poses is in the market for low-cost parts that demand high-speed production, specifically prototyping bureaus.

And this has been your breakdown of Econolyst’s breakdown of HP’s 3D printing process, using a select few cut outs from the complete inographic. I’m not as big of an egg head as the folks over at Econolyst, though, so make sure to look over their beautiful and informative infographic at the Econlyst website.

Hat tip to Oli.

Leave A Comment