Dutch Railways has signed a multi-year contract with digital supply chain service provider DiManEx, to integrate 3D printing into its spare part distribution. The deal came about as part of Dutch Railways’ plan to optimize the efficiency of its coaches and combat issues with physical supplies.

DiManEx Co-founder, Alexander Bours stated “We are excited about the cooperation with Dutch Railways, and proud of the fact that we deliver 3D printing knowledge not as a goal, but as a means to create an agile supply chain that manages any unpredictable demand.”

Advantages of AM spare parts

Founded in 2015, DiManEx provides a cloud-based service that connects companies to a network of certified industrial 3D printing facilities. The company’s plan is to improve manufacturing supply chains through the implementation of additive manufacturing. In the past DiManEx raised $2.7 million in Series A funding, for the expansion of its platform.

The partnership with Dutch Railways began several months ago when the operator began investigating with the possibilities and quality of 3D printed spare parts. After successful tests with DiManEx, Dutch Railways chose to further implement additive manufacturing into its production.

Through this contract, Dutch Railways can utilize DiManEx’s AM capabilities, ensuring its trains continue to run efficiently, even in the case of a replacement part being needed. With 3D printing issues, like costly stock keeping, minimum order quantities and long lead times, are easily resolved. The availability of legacy parts can also be increased by having digital, printable files available for production.

Additionally, by 3D printing tools, Dutch Railways will be able to save time and money on production without having to sacrifice quality. This may lead to further implementation of 3D printing at Dutch Railways.

Joris van de Sande, Dutch Railways’ Supply Chain Operations strategic buyer stated “Today, our main risk in the spare parts supply chain is obsolescence. With DiManEx, we are able to digitize our supply chain, mitigate risks and combat obsolescence. They are an ideal partner to help us build the supply chain of the future.”

Investing in 3D printed spare parts

In an effort to save time and money on parts, several companies have begun implementing AM into their production. Last year, German railway company, Deutsche Bahn, announced plans to expand its 3D printing production after the initial success of 3D printing its spare parts.

Dubai’s Roads and Transport Authority (RTA) signed an MOU with industrial manufacturing company, Siemens, to further implement 3D printed spare parts for the Dubai Metro. Similarly, domestic appliance manufacturer, Electrolux, has also begun trials for 3D printed on demand spare parts.

For more of the latest research related to 3D printing sign up to the Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post Jobs for opportunities and new talent across engineering, marketing, sales and more.

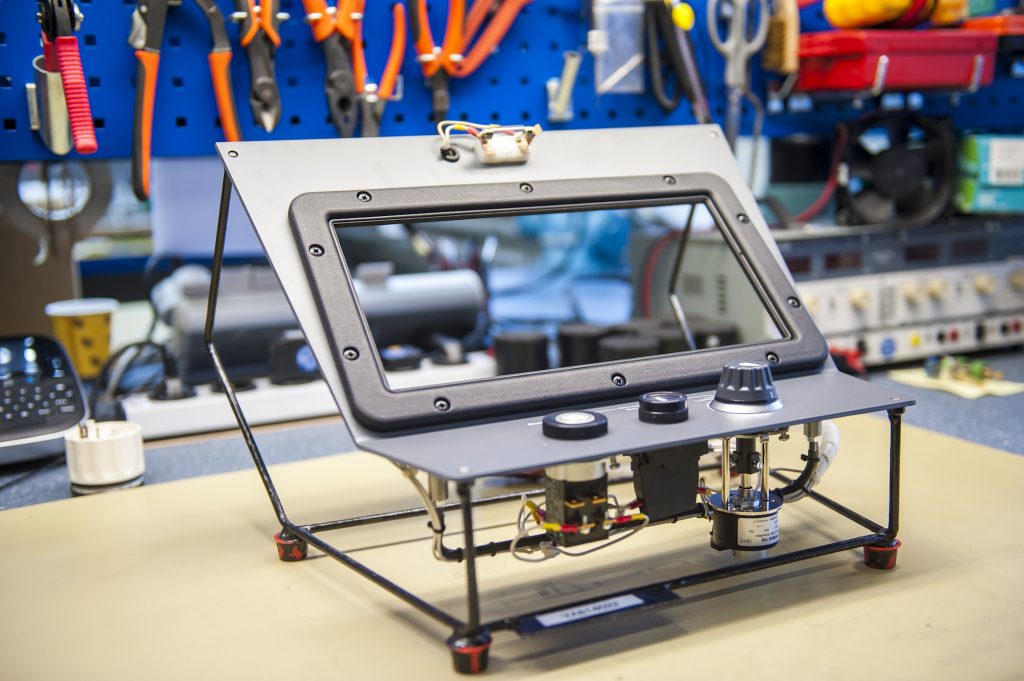

Featured image shows a Dutch Railways’ train. Photo via Dutch Railways.

Leave A Comment