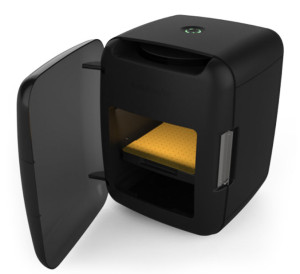

Solidoodle showcased its latest creations at the NYC World’s Maker Faire. Among them were the Solidoodle Press and Workbench, two very interesting and very different machines. Walking into the New York Hall of Science in Verona Queens, Solidoodle was literally the first 3D printer exhibit I ran into, after getting off the shuttle bus and entering the mayhem. The exhibit was packed, but I managed to look over the crowd and push my way to their new flagship printer, the Solidoodle Press, to see it in action. Its sleek matte black outer shell with rounded corners immediately struck me as a smart and deliberate design decision intended to visually sway potential consumers. Made from injection-molded ABS with smooth rounded corners and fully enclosed by glass, it basically looks like an easy-bake oven designed by hip extraterrestrials. Besides a slick look, it has a wide variety of interesting features.

Unlike other Solidoodle machines, it is a completely enclosed printing experience. This means it is safe to print around children and pets without the risk of severe burns from its extruder, which reaches an industry standard temperature of 230 degrees Celsius. The Press has a build volume of 8”x 8” x 8”, and features a heated bed made from aluminum and glass, a spool of their proprietary filament, and a copy of their proprietary software, Soliprint. Linux, Windows and Mac compatible, Soliprint offers a more controlled solution than their previous suggestion, which was that users employ Repetier Host, which can be difficult for some to learn and troubleshoot. Also included is SoliTouch technology, which recalibrates the extruder for a consistent z-offset no matter how unleveled the print bed becomes. This is not a new innovation, but it appears to work extremely well, which would indeed set it apart from other auto-calibration technologies.

Unlike other Solidoodle machines, it is a completely enclosed printing experience. This means it is safe to print around children and pets without the risk of severe burns from its extruder, which reaches an industry standard temperature of 230 degrees Celsius. The Press has a build volume of 8”x 8” x 8”, and features a heated bed made from aluminum and glass, a spool of their proprietary filament, and a copy of their proprietary software, Soliprint. Linux, Windows and Mac compatible, Soliprint offers a more controlled solution than their previous suggestion, which was that users employ Repetier Host, which can be difficult for some to learn and troubleshoot. Also included is SoliTouch technology, which recalibrates the extruder for a consistent z-offset no matter how unleveled the print bed becomes. This is not a new innovation, but it appears to work extremely well, which would indeed set it apart from other auto-calibration technologies.

In August, you could buy the Solidoodle Press for an extremely low price: $350 to $399. They have since upped the price to $449 (retail price $599), but it does not include the SoliCare Protection Plan, which costs an addition $99. It may be worth the additional cost because it covers any defects or malfunctions caused by “manufacturing, shipping, normal wear and tear, or accident.” You won’t find any DIY 3D printed parts inside the Solidoodle Press. The die-cast aluminum innards of this printer are meant to last, but not to be tinkered with. In adding the obviously consumer friendly Press to their arsenal of products, Solidoodle has officially set their sites on the “click-and-print” crowd. I was impressed, but what if I wanted to tinker the living daylights out of my Solidoodle?

Here’s how it looks in action with one extruder:

So, my question is: how does the SoliTouch auto-calibration technology hold up with dual extruders?

Also, don’t forget to check out the collaboration between Solidoodle and Kiki Han, the author of the new children’s book with downloadable characters, Cutie’s Alphabellies!

Leave A Comment