Aurora Labs, an Australian metal 3D printer manufacturer, has announced a non-binding 12 month agreement with the subsidiaries of Fortescue Metals Group (FMG), iron ore developers based in East Perth, to explore the applications of additive manufacturing in mining.

“We’re excited to sign a preliminary agreement with Fortescue and pursue the opportunity to apply Aurora’s Rapid Manufacturing Technology [RMT] to the mining sector. Fortescue are an ideal industry partner for us and they are at the forefront of technological advancements in the mining sector, ” said David Budge, Managing Director of Aurora Labs.

Optimizing mining power plants

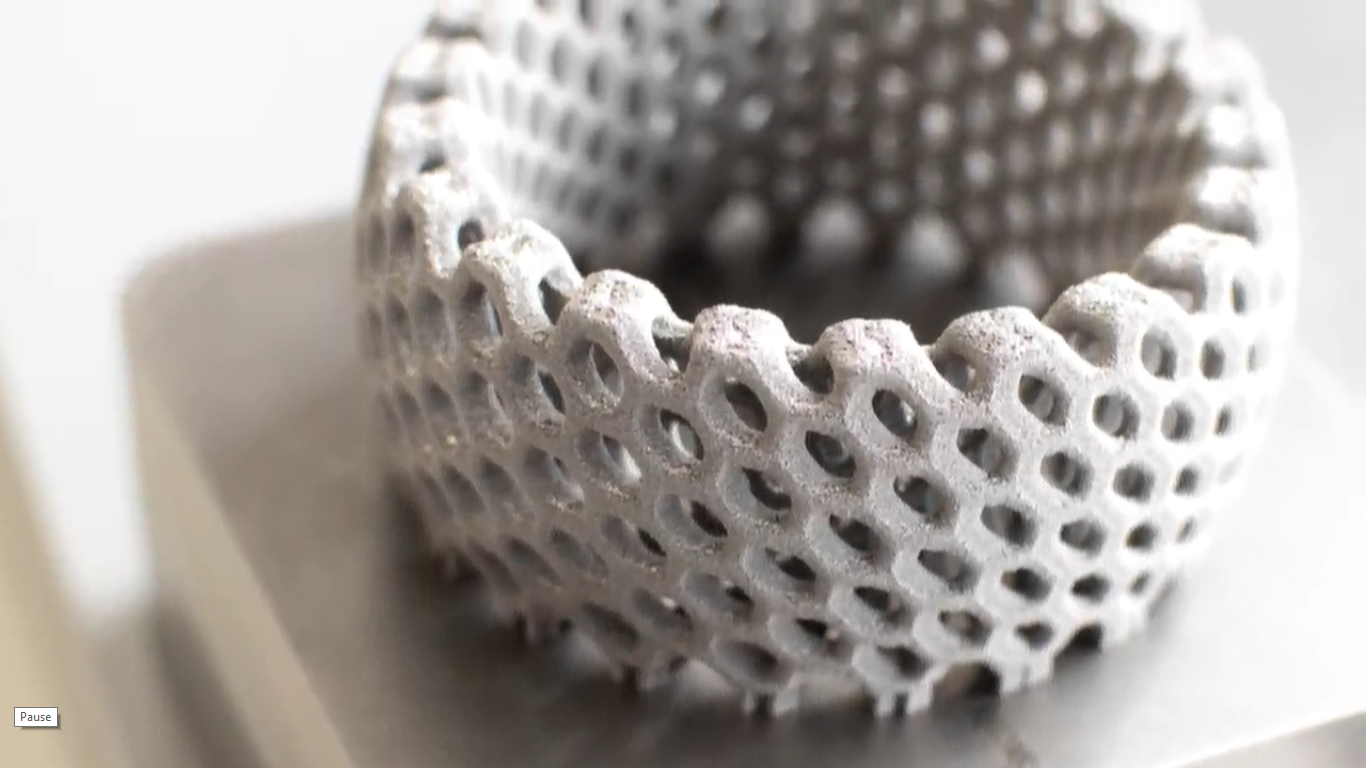

Earlier this year, Aurora Labs introduced its Rapid Manufacturing 3D Printer (RMP1) said to produce metal up to a size of 1.5m x 1.5m x 2.5m (L x W x H) at a rate 100 times faster than existing systems. Leveraging this new powder bed fusion technology, the partners intend to develop processes that could potentially decrease production and operation costs in the mining and resources sectors.

An important application for miners would be to replace parts that have either failed or become obsolete within a processing plant. According to Budge, the advancement of equipment in a plant is known as a “shutdown”.

“Getting parts for shutdowns can be problematic,” Budge explained in a recent interview. “If you can print them in a relatively short timeframe then it makes that whole process a lot more manageable. They can literally print a part on demand.”

“We are building our Industry Partner Program with VEEM, DNV-GL, Advisian, and Fortescue and it’s great to see some of Australia’s largest companies are keen to use our technology. We see this as validation of what we are developing and it acknowledges the high potential that 3D printing has in transforming how parts are created and optimized,” added Budge.

The terms of the non-binding term sheet between Aurora and Fortescue may be extended by mutual agreement.

Additive manufacturing and mining

Recently, Sandvik, a high-technology engineering group, announced plans to open a $25 million specialist additive manufacturing materials production plant in Sweden to focus on the mining and production of fine metal powders.

Following this, Metalysis, a UK metal powder producer, welcomed the Australian Mines resource company which is providing scandium oxide mined in northern Queensland for feedstock evaluation for the progress of its ongoing aluminum-scandium alloy R&D program.

Stay abreast of the latest in additive manufacturing by subscribing to the Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows the RMP1 metal additive manufacturing process. Clip via Aurora Labs.

Leave A Comment