Although it mostly works in the background of 3D printing, Digital Forming is one of the most interesting digital platforms for its ability to offer tools which can help any designer and retailer take personalized digital products to their customers. Now, UK giant Argos has become one of those retailers

The fact that Argos, the UK’s leading online retailer with over £4.1 billion in yearly turnover and some 123 million transactions a year, has turned its attention toward 3D printing, and, specifically, 3D printed jewelry, means that this industry is soon to undergo yet another revolution in less than a decade: from adoption of digital modeling and lost wax casting of 3D printed models all the way to direct metal final production.

Argos’ jewelry website will serve as a test case for implementing a more massive production of 3D printed final products. Together with Digital Forming, who will supply the software technology, and Assa Ashuach Studio, who will contribute with their design expertise, Argos is partnering with EOS, one of the main global producers of DMLS (direct metal laser sintering) industrial 3D printers.

“There has been a lot of excitement about 3D printing and we are just beginning to explore the mainstream application of these techniques,” Neil Tinegate, Head of Digital Innovation at Argos, said. “We are launching the site this week with our partners in the consortium as a trial, to gauge how customers want to engage with it. We will assess results and learnings to inform future decision making in due course.”

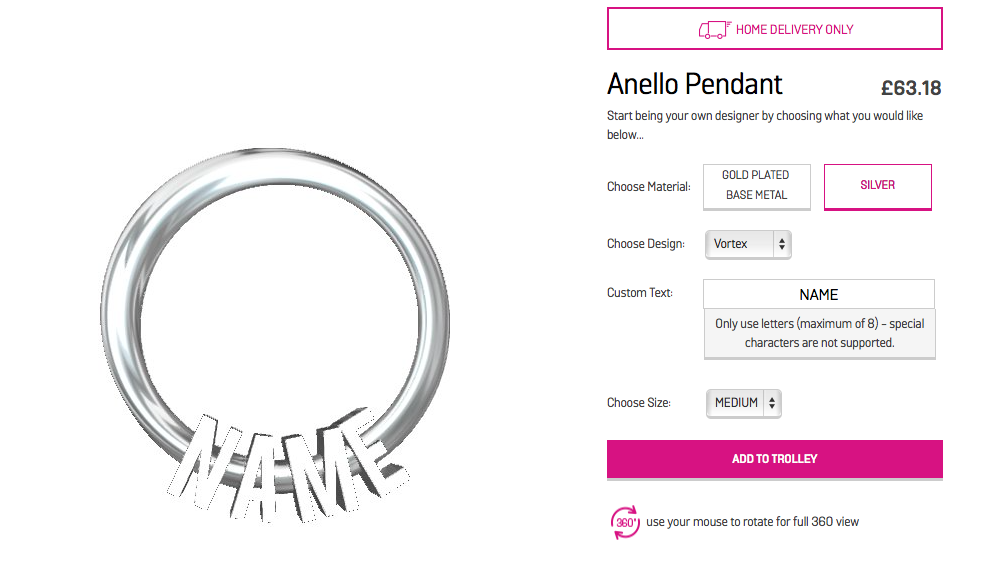

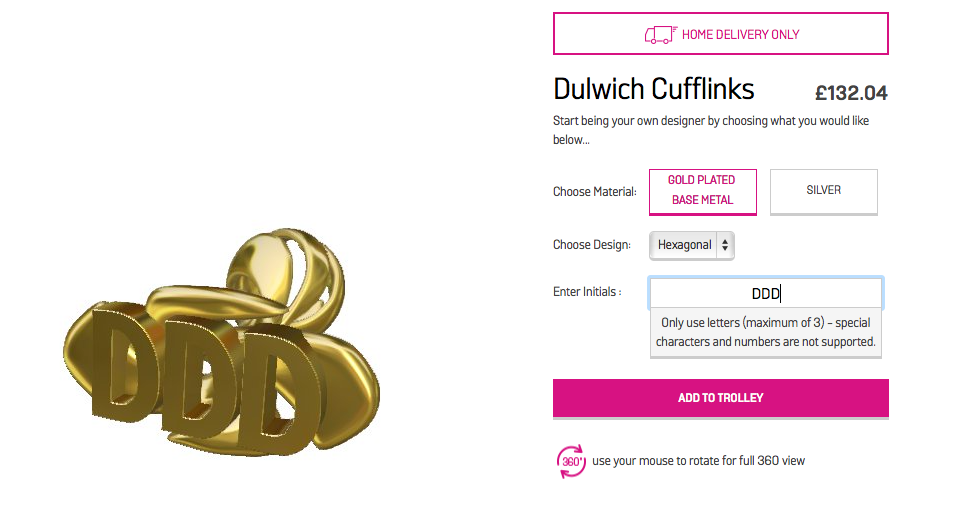

Tinegate confirmed that Argos is starting with jewellery, but they also “see applications for lighting, homewares and other areas in the future.” Using the newly launched website, designers will be able to select accessories from a range of 10 items initially, add their own personal touches, and then 3D printers will bring the designs to life and deliver the bespoke creations in just 21 working days. The available models, which include includes bangles, pendants, rings, cufflinks, and earrings are priced from £50 to £220.

“Argos is leading the way with this project and we are proud to be working with them to bring new 3D printed bespoke products to consumers,” Lisa Harouni, CEO of Digital Forming, added. “We have used revolutionary manufacturing processes to power this website and we are excited by the potential to engage customers in a new way – by inviting them into the design process of their products.”

Argos is not the only huge company to test a 3D printing-based business models. While this does not necessarily mean that the test will be successful and lead to further adoption of 3D printing, it is undeniable that something huge is taking place and this will not simply pass by.

Leave A Comment