Sometimes you don’t need to have used a three dimensional printer to know that you love it. One such printer for myself is the Zmorph 2.0. Why? Because it has seven interchangable toolheads that mean it is able to print with a range of plastics, ceramics, chocolate and cake, as well as offering subtractive and formative fabrication with a milling and engraving toolhead. Five more toolheads are in development. And there’s plenty more happening with the Zmorph team too…

The team behind Zmorph3D, a company originating from Wroclaw, Poland, believe that they are on to something quite special. Special enough to recently make a public offering. Rare indeed for such a small 3D printer manufacturer. As to whether their printer products are special, they may well be right. As to how well the company itself is performing, that’s a wider question. But for now let’s just say that Zmorph3D produce 3D printers that are rare in scope of applications, and are also beginning to perform commerically. Currently the Zmorph team is developing even more functionality for their desktop device via a pick & place toolhead, laser and 5-axis universal toolhead.

Prsemysław Jaworski, CEO of Zmorph3D commented: “These various toolheads are our main advantage over the competition, they replace the standard 3D printer with our machine, a multi-function personal fabricator, a mini-factory that can work in a workshop, office or home. We focus primarily on allowing production in a number of different technologies and materials, which makes Zmorphthe most versatile 3D printer in the world.”

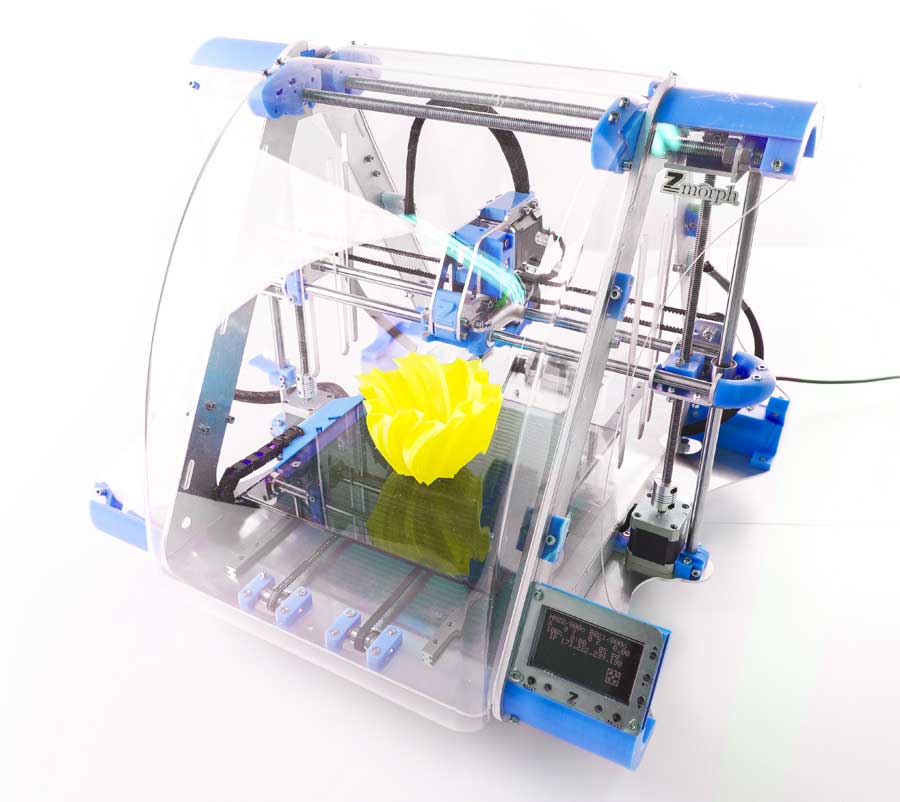

It’s not just about functionality either. Given the direction that leaders such as Stratasys / MakerBot, 3D Systems, Ultimaker, Solidoodle and similar have taken in the desktop 3D printer market, setting their eyes upon black, grey or white streamlined cubes with increasing uniformity, the Zmorph 2.0 takes a utility based aesthetic and yet hones it down to something that genuinely looks appealling. It’s like a beautous RepRap Mendal Prusa, with a feel that is somewhere on the range between industrial and designer.

Zmorph3D has recently been met with success while touring exhibitions with their product range, such as the CeBIT 2014 in Hanover, and the 3D Printer Experience in Haarlem, Netherlands. The company says that their printer has been met with much interest at these events, which has encouraged the company to float its business publicly. Piotr Wąsowskiof Arkley ASF Seed Fund who is a shareholder of the company has mentioned his anticipation thatZmorph3D will debut their offering later this year.

In September Zmorph3D will be opening their own showroom to view and order the companies products.Dick Potharst, co-founder of Multi 3DPrint and exclusive representative of Zmorph in Holland said: “I am very pleased that Zmorph decided to open its concept store just in Haarlem, 3D printing’s time is yet to come… The dynamic development of the technology makes the running of such a place a necessity for us all, we chose a prestigious location with high traffic and good exposure.”

Natalia Ssymacha, general customer relationship manager at Zmorph3D added: “For us it is a huge success and the beginning of the construction of the brand on the Dutch market, where we are becoming more and more recognisable. During this half of the year, we want to sell at least a few hundred of our machines… Most of the positive comments were awarded to Zmorph for the possibility of exchanging toolheads and the ability to print ceramic and cake as well as great design of the machine. It is this uniqueness … that attracted many potential customers..”

For your persusal, we have covered the first Zmorph 3D printer previously here at 3DPI. Let’s take at look at the specifications of the new second generation printer:

- Build envelope: 250 x 235 x 165 mm

- Nozzle diameter: 0.4 mm

- Maximum speed: 500 mm/s

- Recommended speed printing with ABS for layer thickness 0.3 mm: 60-150 mm/s

- Minimum height of layers: 0.05 – 0.025 mm (PLA), 0.1 mm (ABS),

- Total Unit Dimensions: 530 x 555 x 480 mm,

- Total Unit Weight: 25kg

- Extruders: 1.75 mm plastic; 3 mm plastic; Cake and chocolate extruder;

- Ceramics extruder; Dremel mount forCNC milling; Laser cutter; Photo camera controller

- Construction: Frame – Aluminum; other – Polycarbonate and ABS

- Heated table design: 5 mm tempered glass;Kapton heating mat 175w

- Electronics: Sunbeam 2.0 with lpc1769 arm processorwith five driver stepper motors.

- Navigation: LCD display panel

- Firmware: Voxelizer, Smoothieware

The Zmorph 2.0 currently retails at $2,469.80 / 1794,14€ / 15256¥. You can find out more about 3D printers from Zmorph3D here.

Leave A Comment