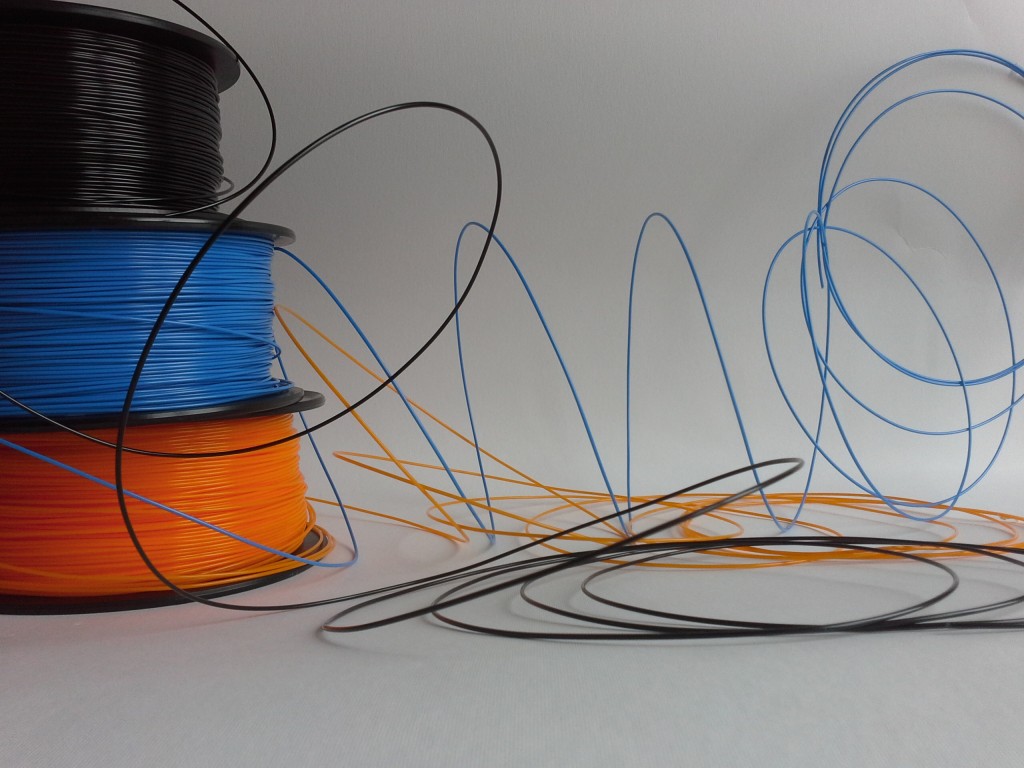

Dozens of new products – including some produced by large petrochemical groups – are literally flooding the market, offering hundreds of different options for 3D printer filaments. Developed by Dogma Solutions, the Filaments Evaluation Protocol (FEP) test implemented by filament distributor 3DFilo aims to provide users, especially those who buy consumables for 3D printing, the criteria for determining whether a particular filament is suitable for a specific use.

When you decide to print something using an FDM/FFF 3D printer, there is always the risk of unexpected errors in the outcome; the are many factors to consider, ranging from non-optimal settings to errors in the digital model, all the way through to the actual “suitability” of the filament used for a specific project. Filament distributor 3DFilo wanted to introduce this rating system in order to help standardize the production process and the results that can be obtained through these treated materials.

Even materials that go by the same name may vary significantly in terms of mechanical, chemical, physical, and thermal properties. In other words, there are different types of ABS, PLA, PETG, Nylon, etc. The coloration alone can alter the ideal printing temperature of PLA, which then affects the material’s characteristics relating to the warping or the adherence to the plate.

Dogma Solutions and 3Dfilo have thus joined forces to help 3D printing adopters select the right material to use. The FEP (click here to download the full white paper as a PDF) is to be considered as a stress test, which, through a series of well-defined parameters, allows for the evaluation of the characteristics of a given material. In fact, the FEP is not a unique standard to be used for the evaluation of a material, but rather as an evaluation protocol to complement – and, in some cases, integrate with – other specific data.

The tower, which has a height of 53 cm, can be printed in an average time of one hour and fifty minutes, with no raft, brim, or skirt. Specific thin and fragile “fins” were added on the chess piece’s sides, along with single layer elements that, in the tower’s upper crown, are used to assess issues relative to extrusion, retraction, and thermal deformation due to cooling.

Once printed, the object must be submitted to a series of stress tests, ranging from pressure, shear, and even the paintability, Upon completion, the FEP yields what Dogma Solutions defines as a degree of judgment on a unipolar, odd Likert scale (known as “Degree of Likert Rating” or “DLR”). This is basically an evaluation on how suitable a material is for a particular project.

The development of standards and protocols for evaluation is a necessary stage in the growth of any industry, and it is even more necessary in an industry that, by definition, allows for the creation of objects with unique properties. Playing with matter is already complex enough. Getting to know the material you intend to mold can make all the difference between a mediocre product and a perfect one, like drinking a glass of quality wine and just any wine.

Leave A Comment