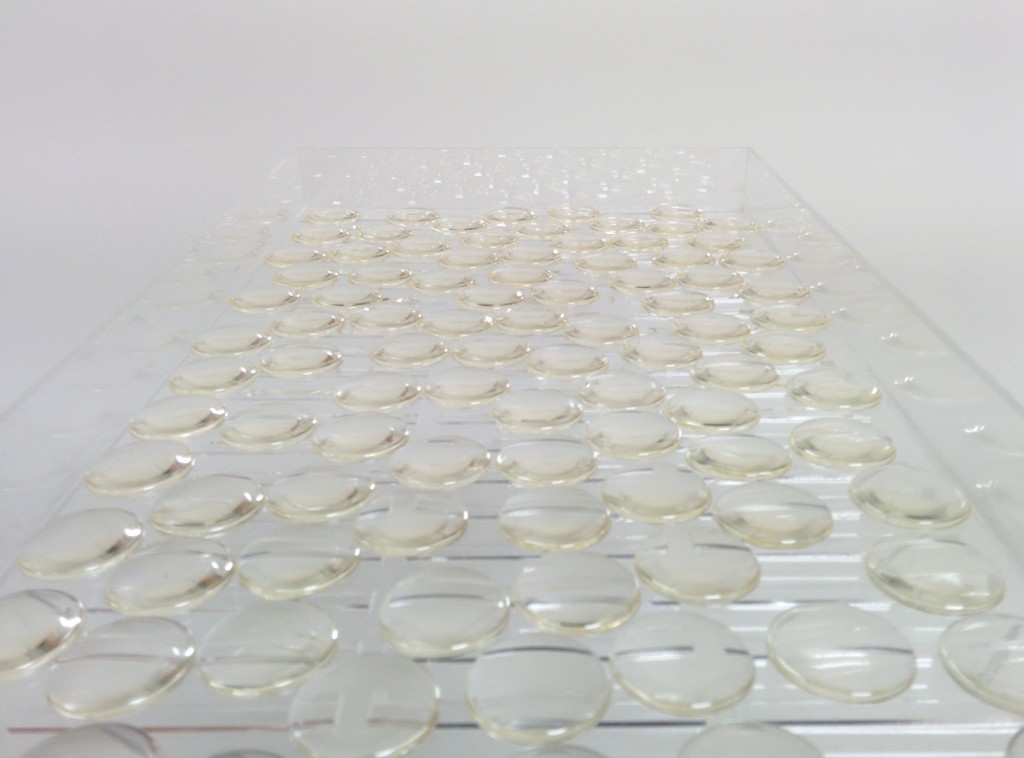

Since being founded by Richard Van De Vrie in 2009, the Netherlands-based additive manufacturing company LUXeXcel has been a stand out with the only process devoted entirely to 3D printing transparent optical components, such as lenses, prisms, and other complex surfaces. Their prized and patented “Printoptical Technology” is still the only 3D printing method capable of producing well-defined optics within smoothly 3D printed transparent objects, which works by using photo active resin during the object’s curing process.

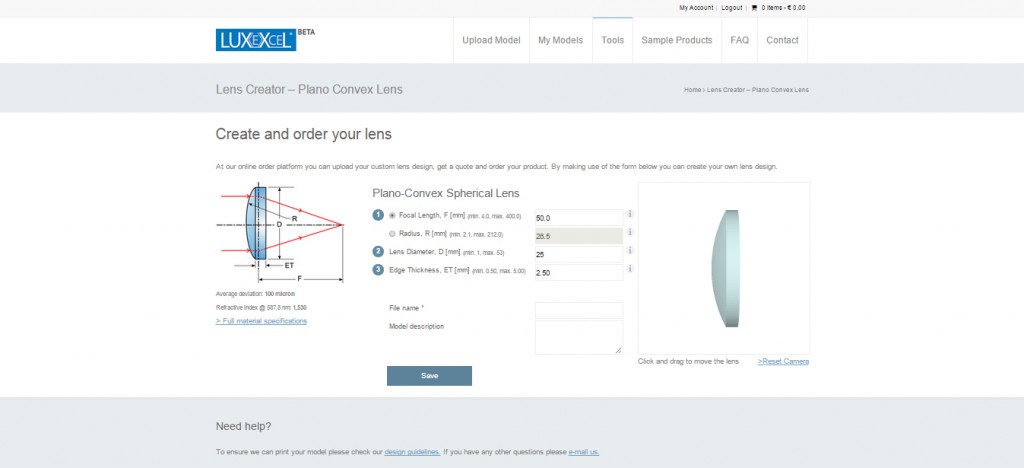

Earlier this year, the Berlin-based trinckle introduced their highly capable platform, designed as 3D modeling tool that operates through a cloud engine, equipped with mass customization of 3D printable objects. By allowing customers to access this specialized online lens creator software, LUXeXcel is opening up their high quality optic manufacturing technology to fit the needs of any desired transparent 3D printed lens. Together, the LUXeXcel team and trinckle 3D have released two individual lens creator platforms thus far, one to design convex lenses and the other for concave lenses. The two trinckle 3D-powered programs represent the next-level of 3D design software, able to efficiently design and perfect the model of the lenses using a few parameters, such as the focal length and lens diameter. After this information is submitted into the chosen design tool software, a model preview of the custom-made 3D file is presented and ready to be ordered right on the spot.

“With our new design tool we want to take the next step in opening up the world of optical development. Lowering the bar to make use of optimized optics for its application, and taking away the limitations of standard stock products will be a game changer for many designers that use optics in their products,” says Peter Paul Cornelissen, Head of Marketing & Online Business Development for LUXeXcel.

LUXeXcel’s use of 3D printing technology for the production of transparent optics has already proven beneficial as far as cost and time efficiency goes, but their two new lens creator design tools will now help designers and businesses create and mass produce unique concave and convex lenses that would be far from affordable or accessible through the channel of traditional optics manufacturing. LUXeXcel and trinckle 3D can now allow customers to create and obtain a high quality 3D models of their custom lenses free of charge, saving prospective 3D printed optics consumers time, money, and from the limitations that have been wrought from lack of innovative manufacturing methods for the industry of optics.

Leave A Comment