It goes without saying that, as 3D printing technology constantly evolves, the manufacturing companies behind the production of these machines and their accessories are in a constant state of flux, as well. The latest instance of this ‘evolution’ is coming out of Roscoe, Illinois, where the large-format industrial 3D printer manufacturers formerly known as 3DP Unlimited have just announced a new name and new 3D print-based technological upgrades. They will now blanket their industrial 3D printing products under the slightly shortened name 3D Platform (3DP), marking the company’s next step in upcoming investment endeavors and expansion strategy.

Already quite established in the industrial-grade printing community, 3DP is planning on taking their past success within the industrial market to invest further in their printers and services. “We are pleased with 3DP’s early performance in the growing large-format market and are now increasing our investment in the next-generation of technology, products, partners and people,” said CEO of 3DP Robert Schroeder. 3DP will work towards improving their product’s capability, establishing more industry relationships, and expanding their staff to help enhance sales and customer support.

It’s not just putting more money into making their existing platform more enticing either, 3DP seems adamant about becoming more globally-connected as well, boasting a network that is now composed of over 40 countries ranging from Belgium to Bangladesh. “3DP has had a tremendous response from global distribution channels and our team has been actively developing a robust reseller network, which we are increasing our investments in through targeted training, support,and service programs,” Schroeder continued.

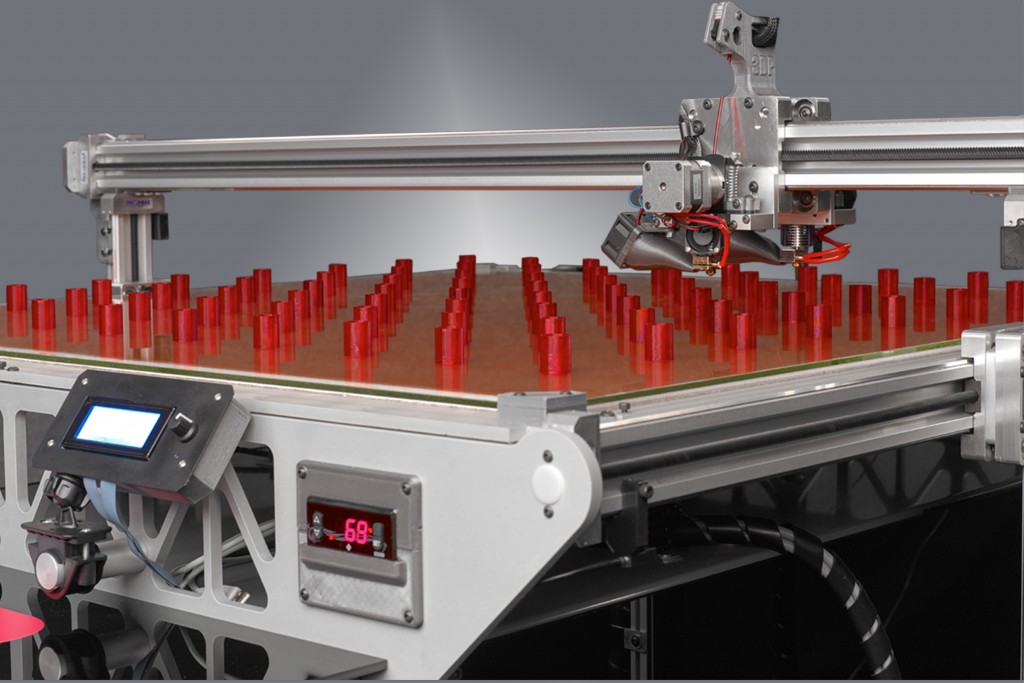

Before the recently announced name change and expansion, 3DP had already made a name for itself by featuring their industrial-grade 3DP1000 printer at events such as ATX West and launching a leasing program to help make their product more affordable. In addition, upgrading their technology, support staff, and global network, 3DP will also reportedly focus on making their product more versatile in regard to its applications. The company hopes to satisfy the industries of architecture, education, construction, and aerospace, just to name a few.

“SurePrint is equivalent to swapping your car’s 200 HP motor with a 375 HP motor—you immediately gain drive torque. And when you add smart traction control, you gain greater control and precision,” says John Good, Vice President of 3DP’s Sales & Marketing.

As appropriate as Good’s horsepower analogy may seem, he could have taken it even further and said that using the SurePrint Servo Technology printer motor would be like swapping out your gas engine for an electric one. The SurePrint Servo motor uses two-thirds the energy of their previous model, and also reportedly generates half the heat too. The 3DP team made energy efficiency a priority in this new technology in order to try and benefit both the environment in general and the immediate environment surrounding their printers.

3DP has developed the SurePrint Servo as a service to both new and preexisting customers. The motor was designed with the same framework as their previously implemented stepper motors, making the SurePrint backward compatible and easily upgradable. “The SurePrint Servo is a win-win-win. It allows operators to print faster, increase accuracy, and decrease energy usage,” Good continues. “Not only will this be available on new machines, but these advancements are available for any of our existing units in the field.”

Trying to take advantage of every aspect that being ‘open’ has to offer, 3DP also claims to be improving access to the manufacturing process and optimizing the versatility of their printing materials. The 3DP1000 printer, for instance, was designed with an accessible platform that would allow for other technologies such as electronics, sensors, and switchers into the print without the restrictions that hinder enclosed industrial printers. ‘Core modeling’ will also be upgraded within 3DP’s products, which benefits both print time and cost efficiency by rezoning the 3D objects and configuring the different percentages of material infill that each particular part needs for proper functionality and support.

The transformation into the shorter company name plays into the fact that 3DP is focusing on shortening print times and tightening up operations, showing that sometimes less can mean more. But, when it comes down to it, more is precisely what 3DP is aiming for with their expansion and improvements. It will be curious to see where these investments and open platform upgrades can carry these industrial-grade printers, such as the 3DP1000 and beyond, but the one thing that is certain is that 3DP is attempting to showcase their big printers under an even bigger spotlight.

Leave A Comment