3D printing is slowly but surely changing the fashion world as we know it, from the runway to online retail. Some of today’s loudest fashion statements are coming fresh out of a 3D printer. Beyond just being utilized to create printed garments and accessories, 3D printing technology is also being looked upon as a muse to help innovate classic techniques, such as knitting. One company that has reinvented the historic knitting machine is the Central London-based Unmade, located in the Makerversity, an incubator and service provider for various tech-based startups in the London area.

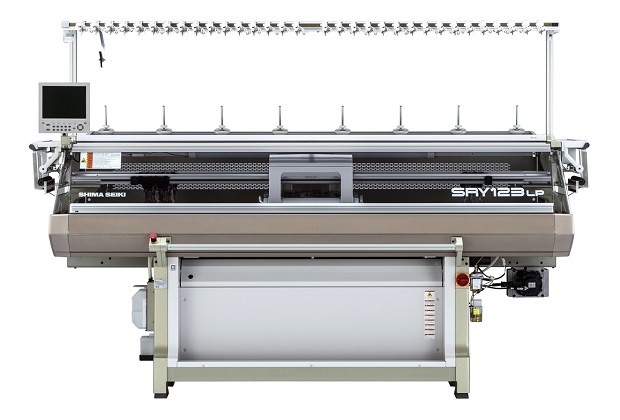

Unmade borrowed the general mechanics and functionality behind 3D printing technology, taking the relative coding and implementing it into their knitting machines, which in turn has made these old-school devices transform suddenly into a new and innovative machine.“Knitting is the future of textiles,” Unmade’s Ben Alun-Jones tells The Guardian. “All the things people dream of doing with 3D printers is one of the oldest things going.” By re-engineering these knitting machines to function like a 3D printer, Unmade is able to run personalized designs through specialized software and ‘print’ personalized knitted designs to order.

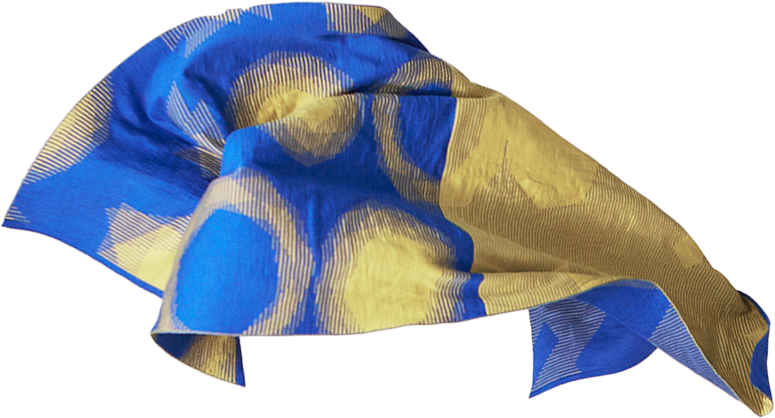

Not only does the art of knitting become more efficient with this reinvented technology, it also allows for less material waste and more personalized products. Unmade’s consumers are able to choose and customize a product, at which point it will be knitted to order, ensuring that the company only makes product that are destined to sell right away. By placing the power in hands of the user, Unmade’s consumer base will be able to own a product that was specially printed just for them.

“We are building a completely new experience for the customer where you can be part of the creation process,” said Alun-Jones. “We have made our own file format that is like an MP3 is to music – we have created a .KNIT which is a file format for knitting.”

Even the file formatting has been influenced by 3D printing technology, their .KNIT files act similarly to .STL files, by slicing and preparing the knitting machine-3D printer hybrid for action. Unmade currently has a pop-up shop open in London’s Covent Garden until Christmas, where you can see how their knitting machine works, try on samples, play around with digital designs, and even create and ‘print’ your own knitted garment. This uniquely designed knitting process does come with a price to pay though, as scarfs and jumpers cost £60 and £120 respectively. But I can certainly see that price dropping as more fashion designers start implementing 3D printing technology into the art of knitting and other traditional processes. In the meantime, Unmade is proving to be one-step ahead of most garment makers, and have potentially created the next stage in tech-infused knitting methods.

Their website will officially go live on November 16th.

Leave A Comment