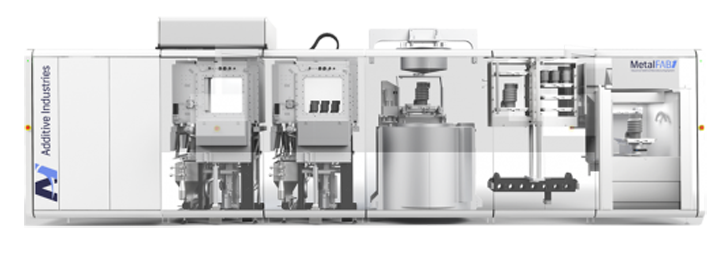

The MetalFAB1 metal 3D printer is set to change the industrial 3D printing space with unprecedented levels of automation and quality control. Though the system itself was not physically present at formnext, the virtual unveiling made a big enough splash for Airbus to install one in their Airbus APWorks manufacturing facilities. Since then, Additive Industries has secured two more MetalFAB1 Beta customers, Kaak and United Grinding Group, selling the Dutch manufacturer out within just three months after market launch.

At the fourth edition of their Additive World Conference in Eindhoven, The Netherlands, Additive Industries disclosed their customers. Kaak Group, also Dutch and a partner of Additive Industries since 2014, is a food tech company that focuses on automated baker systems. Kaak CEO Lodewijk van der Borg explains how they will use the technology, saying, “We will use metal additive manufacturing to produce parts for our dough handling equipment and foresee an important role for 3D metal printing in our future global spare parts supply chain.”

United Grinding Group has recently initiated a joint venture with Inspire, IRPD in St. Gallen, Switzerland., which will see them use the MetalFAB1 to expand their production capabilities. CEO Stephan Nell explains, “We see metal additive manufacturing as a promising addition to our subtractive business. We have great expectations of our collaboration with Additive Industries.”

With all three deals, Additive Industries has sold out of their available MetalFAB1 machines just three months after launch at the end of last year. The company will now start increasing series production of the systems, with co-founder and CEO of Additive Industries Daan Kersten saying “We expect the first series machines to leave our factory before the end of this year.”

Leave A Comment