3DCeram, a French 3D printing OEM and service bureau specialising in 3D printing ceramic components and art, has announced a partnership with Sinto, a Japanese foundry equipment manufacturer.

The Nagoya City-based OEM has cited its desire to make greater use of 3D printing in its operations. Reciprocally, 3DCeram will be able to strengthen its operations in Asia, expand them across the Atlantic to the US, and spend more on research and development.

Sinto enters the 3D printing fray

Sinto’s global network extends across 48 countries, and it employs nearly 4000 people worldwide. As part of its research and development, it uses ceramics to improve the quality and efficiency of its metal casting processes.

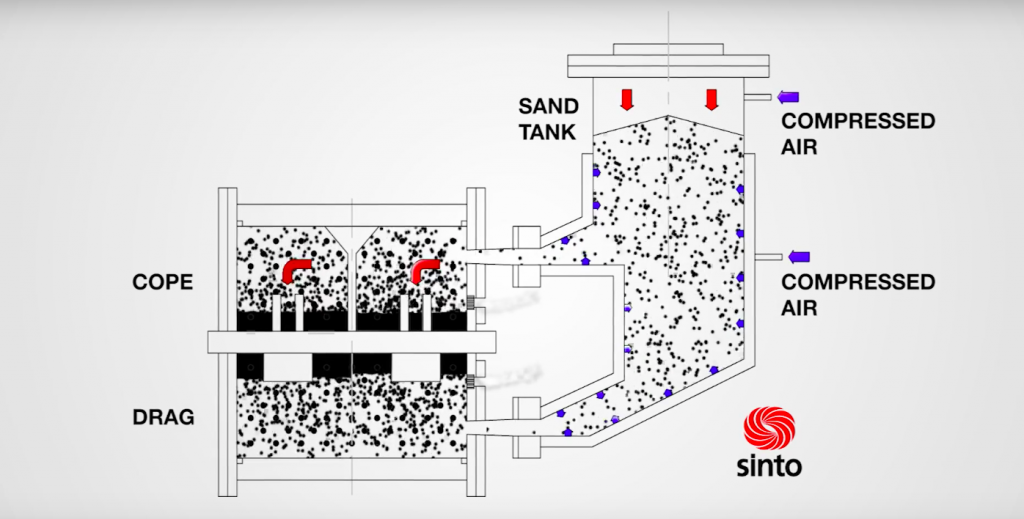

Sinto currently uses its own vacuum forming technology to cast complex ceramic shapes for semiconductors, liquid crystal displays, and electronic parts.

Explaining the reasoning behind the the partnership, Sinto noted the benefits of 3D printing in “giving greater freedom to form shapes” and in having “a shorter delivery time” compared to its existing molding and forming methods.

Sinto also acknowledged the use of 3D printing in the biomaterials, aerospace and energy sectors, and expected demand for ceramics in batteries to increase. For these, Sinto will make use of 3DCeram’s manufacturing equipment, expertise and European distribution.

A mutually beneficial partnership

This announcement follows 3DCeram’s reports of significant financial growth in 2016 and its participation in EU Commission backed Cell3ditor clean energy project earlier this year. However, after the partnership, 3DCeram is set to become a consolidated company under Sinto, which will also acquire a majority stake in 3DCeram’s shares.

Commenting on the partnership, 3DCeram directors Richard Gaignon and Christophe Chaput explained, “we want to take another step. We want both to consolidate the undisputed benchmark that 3DCeram is in the field of 3D ceramic printing and to strengthen our position as an engineering company…on a planetary scale.”

For more information on all the 3D printing business news, subscribe to our free Industry newsletter. Also follow us on Twitter, and like us on Facebook.

Featured image shows Sinto’s current vacuum forming process for materials. Photo via Sinto.

Leave A Comment