This edition of 3D printing news Sliced features stories from CFM International, GE, Safran, Materialise, 3D Hubs, Autodesk, HP, UniZ, Niedersachsen ADDITIV, MIT, Ohio State University, Nottingham Trent University, Atum3D, Sharebot and Space for Giants.

Stormy skies over GE and Safran, calm seas for UniZ, Materialise and Niedersachsen ADDITIV

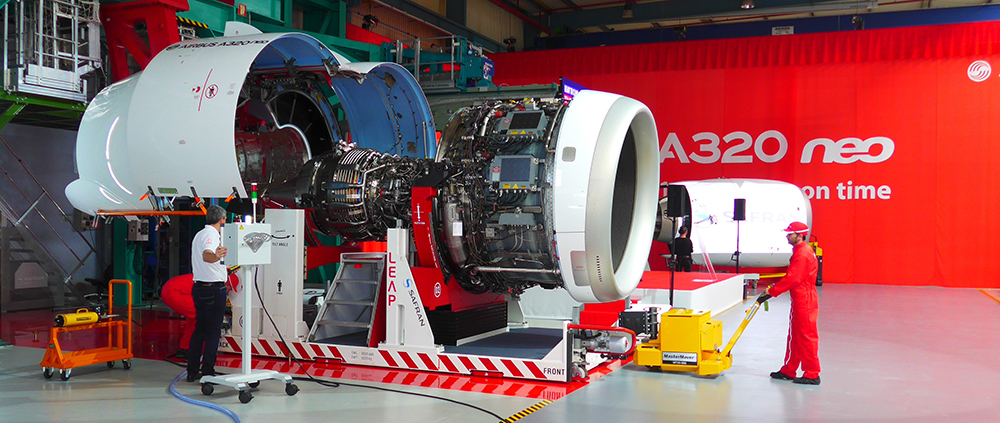

CFM International, a joint venture between GE Aviation and Safran Aircraft Engines, (two significant users of 3D printed parts), is reviewing its Leap-1A engine fleet after the coating of a turbine shroud began flaking off mid-flight. The spaces in the coating allowed air passing through the Airbus A320neo’s turbine system to escape, causing dramatic changes in gas exhaust temperature.

While the LEAP contains 19 3D-printed fuel nozzles, these static turbine shrouds are made in a different manner from ceramic matrix composites.

Although GE is responsible for delivering turbine parts to CFM produced engines, Safran has set aside $58 million to repair in-service engines “to err on the side of caution,” according to Safran CEO Philippe Petitcolin.

Belgian OEM Materialise has opened both a new 5,500 m² headquarters in Leuven as well as a new production facility in Wroclaw, Poland, which has capacity for over 80 SLS printers.

UniZ, the start-up behind the successful SLASH SLA 3D printer nominees on the Industry Awards “startup of the year” shortlist has raised over $6 million from investors Beijing DeLian Express Investment Management and Cheng Congwu. Commenting on the deal, DeLian Express’ Xiao Ran expressed his confidence in UniZ’s “core technology,” its “intelligent manufacturing,” and its move towards “industrial 4.0.”

Niedersachsen ADDITIV, a €1.2 million additive manufacturing education facility in Hanover, Lower Saxony, has been opened by state government minister Olaf Lies. The state-funded facility will assist SMEs in additive manufacturing, host training events and seminars, accommodate research into additive manufacturing processes, and investigate the economic impact of 3D printing.

A boost for microfluidic accuracy and wireless communications range

In a new paper from MIT, researchers demonstrate a 3D printed device for making nanofiber meshes suitable for use in advanced filtration systems, and as scaffolds in tissue engineering. With minute channels, the equipment is essentially a microfluidic device, that can be unconvetionally produced without the need for a cleanroom.

According to the paper’s lead author Luis Fernando Velásquez-García, 3D printing the device means that, “in the next few years, nobody is going to be doing microfluidics in the clean room. There’s no reason to do so. 3D printing is a technology that can do it so much better — with better choice of materials, with the possibility to really make the structure that you would like to make.” The full study is available to read online here.

Meanwhile, at Ohio State University’s ElectroScience Laboratory, researchers have been awarded a $300,000 National Science Foundation (NSF) grant for the development of their 3D printing facilitated antennas, which will reach beyond the overcrowded microwave frequency of common devices.

Big product announcements from atum3D and Sharebot ahead of Formnext 2017

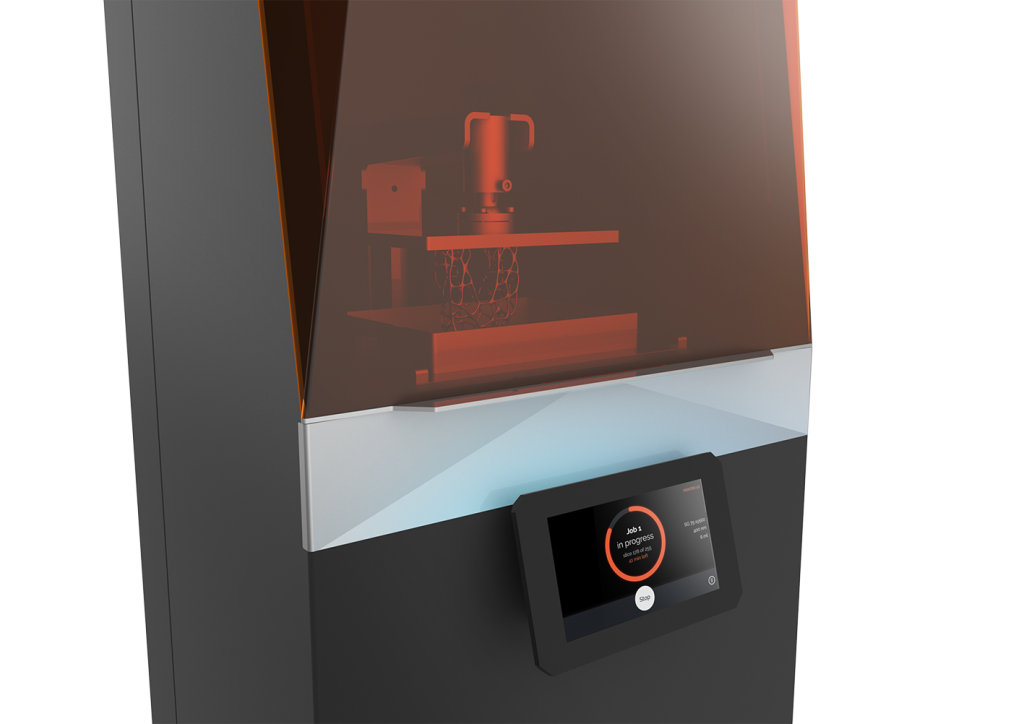

atum3D has announced that it will be launching three new products at Formnext 2017. The first product is the DLP Station 5, a new Digital Light Processing 3D printer with an open resin platform. The second product, to tie in with the first is the “Operator Station” software, which applies MAGS AI technology to model preparation.

The final product is a new range of “Excellence Packs”. These are industry materials and software packages tailored to product design, dentistry, jewellery and manufacturing. atum3D will be exhibiting at Formnext stand 3.1-C78, 14-17 November.

Also at Formnext, Sharebot will be launching its large Antares SLA 3D printer. The Antares has a build volume of 250 x 250 x 250 mm and is compatible with the PR-S resin as well as a number of slicing softwares. The Antares is connected to the internet and can be remotely managed. Sharebot will be exhibiting at stand 3.1-A48 14-17 November.

3D Hubs on board, and the elephant in the room

Jack Davies, a British product design student at Nottingham Trent University and intern at 3D Hubs has designed an electric longboard using HP’s Multi Jet Fusion technology and Autodesk CAD software. The “Fusion E-board” took less than a week to build, and its electronics enclosures and its motor mounts were 3D printed at a cost of €550.

3D Hubs also recently released their most recent trends report. The data shows a number of interesting trends including the fact that London has now overtaken New York are the region with the most number of active 3D printing hubs.

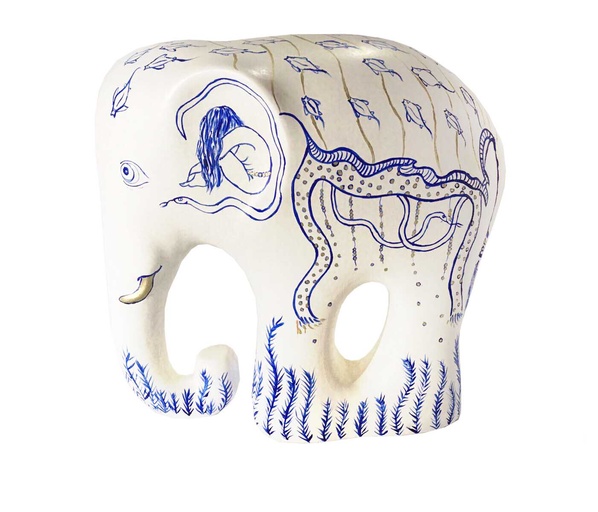

Elephant protection charity Space for Giants is raising money for its work in Africa through two unique events. Tonight at the Brooklyn Bowl, New York City, the charity is hosting the Stampede of Sound concert with live music and a 1 meter tall 3D printed elephant made by a collaboration with MyMiniFactory and iMakr. At 2pm ET, it will also be launching an online auction of 7 limited edition 3D printed elephant sculptures, lovingly hand painted by artists from across the U.S.

The design of the Space for Giants charity elephant is based on a model created by Raymond Leonardo Chandra, which can be downloaded for free here.

For more news on Formnext 2017 and 3D printed design products, subscribe to our free Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows Pamela Caspar’s hand painted Phantom elephant (2017) Lot Number 2 in the Space for Giants charity auction. Photo via Paddle 8.

Leave A Comment