Optomec, the American company behind LENS additive manufacturing and Aerosol Jet Printing technology, has acquired Huffman LLC, a CNC and laser cladding machine supplier and service provider from Clover, South Carolina.

Though full terms of the acquisition remain undisclosed, Optomec has confirmed that this strategic move seeks to leverage Hoffman’s wealth of experience in the gas turbine market.

David Ramahi, president and CEO of Optomec comments:

“With the Huffman acquisition, we aim to expand the use of DED/LENS repair for the existing installed base of more than 100,000 gas turbines and engines,”

He says, the company also hope to leverage “that expertise to drive greater adoption of cost-effective repairs for mainstream industrial applications.”

Optomec Laser Engineered Net Shaping

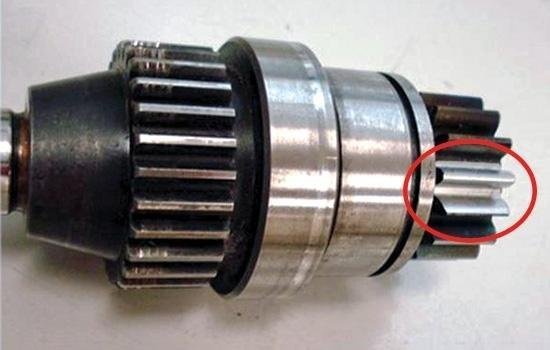

Headquartered in Albuquerque, New Mexico, Optomec was founded in 1997 to deliver the proprietary LENS technology developed at Sandia Labs. LENS, short for “Laser Engineered Net Shaping,” is a metal fabrication technique based on directed energy deposition (DED) 3D printing. In this method, powder is blown through a central nozzle into the focal point of 2 – 4 lasers. An inert gas sheath ensures the precise placement of the powdered particles, and upon contact with the lasers they melt to create a molten track.

Due to the nature of this method, LENS is especially suited to adding material to conformal surfaces, finding it a range of applications in machine maintenance and part repair.

Through Optomec, LENS is offered as both a turnkey system, and an upgrade for existing multi-axis CNC milling machines.

Huffman directed energy deposition

Experience with DED technology is something Optomec shares with its new acquisition. At Huffman, DED is realized as Laser Cladding, or Laser Powder Fusion™ (LPF), and Laser Fusion Welding (LFW) technology. These technologies are harnessed by a range of 3, 4 and 5 axis machines provided by the company.

Huffman was founded in 1961 and, at present, its partner portfolio is built up of the likes of Rolls-Royce, Caterpillar Solar Turbines, Siemens, Pratt & Whitney and TWI. GE is also a noted partner of the company. At GE Power in particular Christopher E. Thompson, General Manager Product Service, said “Optomec and Huffman joining forces is exciting news in the additive manufacturing space,”

“…Optomec’s innovative and affordable solutions in this space, combined with the robust, production-friendly equipment and intuitive user interfaces provided by Huffman are sure to enable new leaps in free-form additive manufacturing for repairs, new part build and hybrid manufacturing.”

Nominate your 3D Printer of the Year in the 2019 Industry Awards now.

For all of the latest business updates, subscribe to the Industry newsletter, follow us on Twitter and like us on Facebook.

Join Jobs to find your next opportunity.

Featured image shows Optomec DED based LENS technology, 3D printing onto a premade metal surface. Photo via Optomec

Leave A Comment