FIT Additive Manufacturing Group has acquired a Hot Isostatic Pressing (HIP) machine from Quintus Technologies, a Swedish high pressure technology expert.

The HIP machine will ensure that after post-processing, 3D printed metal parts pass the quality assurance tests as smoothly as possible.

Carl Fruth, CEO FIT AG, explained, “We have evaluated the requirements of 250 international industrial customers for five years, and HIP turned out as an answer to many quality issues. The results that can be achieved by combining AM and HPHT are highly encouraging. It’s beyond all question that our customers will benefit strongly by this partnership.”

“I even think that all additive serial manufacturing will experience a big boost when integrating HPHT as a post-processing service”

Developing FIT

Based in Bavaria, Fruth Innovative Technologien (FIT) was founded in 1995, by Carl Fruth, a former application Engineer at EOS. FIT is also the former parent company of Netfabb, a 3D printing software now owned by Autodesk.

Including Germany, FIT has operations in four countries, U.S, Japan, Romania, and Russia, where FIT also founded the company FITNIK, a collaboration with the Russian aerospace engineering company NIK Ltd.

FIT largely specializes in metal 3D printing and has machines from industrial manufacturers like, EOS, SLM Solution, Arcam AB, Voxeljet, and Sintermask, which was acquired by FIT in 2008.

Post-processing metal 3D parts

Powder bed fusion is one of the most widely used metal 3D printing processes. A high energy laser beam is fired onto a bed of metal powder, which creates a melt pool and then cools down to form a solid layer. This process continues until a full 3D model is formed.

One of the problems associated with this process is forming of pores and keyholes in the metal part which could weaken its strength. Pores in a 3D printed metal part could form if the laser temperature is too high. This causes the powder particles to penetrate the layer below.

To rid the metal part of such deficiencies, a post-processing method like HIP is essential to ensure that the part is mechanically fit for the purpose it was designed for. Furthermore, HIP processing also increases the density and fatigue resistance capacity of the part.

On the acquisition of the HPHT machine by FIT and what benefits it could bring, Jan Söderström, CEO of Quintus Technologies, said, “We have high expectations in the industrialization of HPHT post-processing by leading AM specialist FIT Additive Manufacturing Group.”

“The overall optimization of process parameters and material-specific heat treatment parameters in an in-line, lean-process production will lead to a new high-quality benchmark while reducing costs.”

Vote now in the 2019 Industry Awards.

For more news on metal additive manufacturing subscribe to our 3D printing newsletter and follow us on Facebook and Twitter.

Register at our Jobs site to receive career updates.

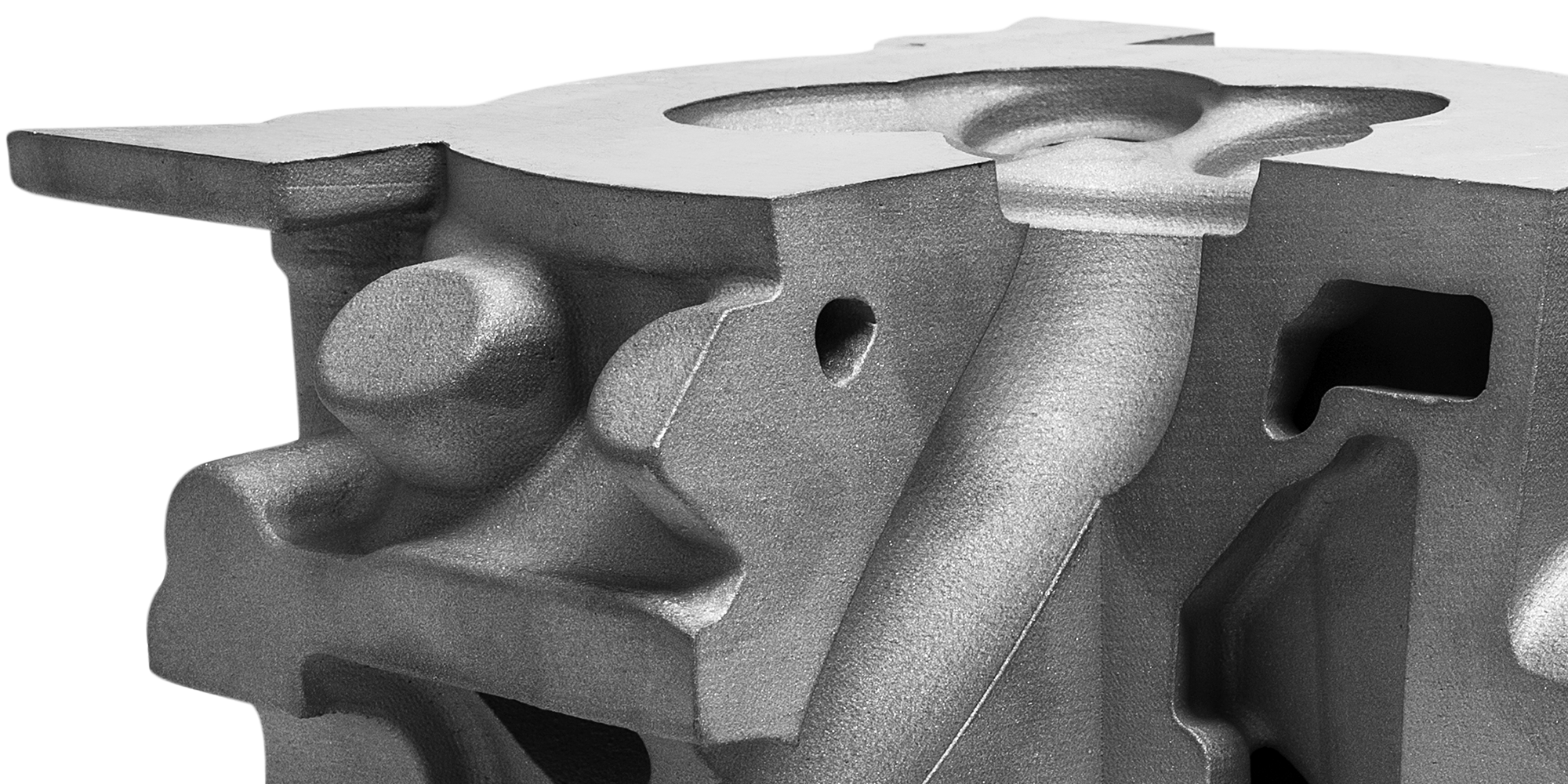

Featured image shows a metal 3D printed part after HIP post-processing. Image via FIT.

Leave A Comment