To read part two of this two-part series on 3D printing in Chattanooga, click here.

My wife, Danielle, and I just left the Gig this morning, the 1 gigabit per second fiber optic network that connects all of Chattanooga to the Internet, and I can honestly say that we will miss it. More importantly, we’ll miss the city that built it. And, though we went there to cover the GIGTANK event and the 3D printing start-ups that pitched their companies to investors there, it will be impossible to review GIGTANK without also writing about Chattanooga, Tennessee because, as you’ll begin to learn if you haven’t already, the city is and will continue to be home to some really amazing innovations as the 3D printing industry develops. So, I’ll break this review up into two parts, first covering the event and the 3D printing companies themselves and, second, writing about the city and how it’s setting itself up to be something like, but totally different from, the Silicon Valley of the Southeast United States.

GIGTANK is a start-up accelerator that takes a number of promising entrepreneurs and equips them with all of the resources and mentors the city has to offer, until, two months later, they come out with full-fledged companies. The series culminates in Demo Day, in which the start-ups have an opportunity to present their visions, accomplishments, and business plans to a crowd of venture capitalists and angel investors who can help those start-ups hit the ground running with enough funding to bring their products to market.

The accelerator originally started as the brainchild of Sheldon Grizzle, founder of the Chattanoogan incubator CO. LAB. As you’ll hear in part two, CO. LAB is just one of many endeavors taking place that are continuing a total transformation of the city. Up until now, GIGTANK has focused on healthcare and smart grid companies that seek to either take advantage of Blue Cross Blue Shield’s presence in the city, along with the five major hospitals there, or Chattanooga’s phenomenal smart electric grid, run by the municipal power company, EPB, and made possible by the Gig (more on that later, too). It wasn’t until Grizzle stepped down last year and was replaced by Mike Bradshaw that GIGTANK broadened its focus to include 3D printing.

I spoke with Mike about his decision to focus so heavily on 3D printing this year. Mike tells me that, when he took the job at CO. LAB, he wasn’t going to be able to accept payment at his new position, due to contract issues with his previous employer. So, in lieu of payment, the director made only one demand: that they use what would be his first month’s pay to purchase a 3D printer. CO. LAB first began with a MakerBot Replicator 2, later receiving larger machines, like the uPrint from Stratasys. Mike’s story reflects his understanding of the underlying power of 3D printing to speed up businesses. As he explained it, his plans to include the technology in GIGTANK 2014 seemed logical, almost obvious. In fact, he’d wondered why there hadn’t ever been a 3D printing accelerator before. Recognizing the inevitable collision of two huge trends, start-up incubation and 3D printing, Bradshaw knew he had to launch the first 3D printing accelerator in the nation.

GIGTANK 2014 was made up of ten different start-ups, with seven building their businesses around 3D printing and only three working solely on healthcare and the smart grid. The companies selected flew in from as far as Canada, California, and Florida to work under the leadership of expert mentors and business leaders with access to a breadth of resources and the world’s fastest internet. So, while Doug Speight, Senior Commercialization Manager at Oak Ridge National Laboratory and founder of Cathedral Innovation Group, acted as the entrepreneur in residence, guiding the teams on how to build a successful business, specialists in 3D printing, the smart grid, and healthcare worked with them to improve their apps, printers, and sensors. At the same time, design experts and industry professionals coached the companies on how to polish their presentation skills, their web presence, and their marketing aesthetics. Finally, they’d use those newly refined skills to acquire seed funding at Demo Day.

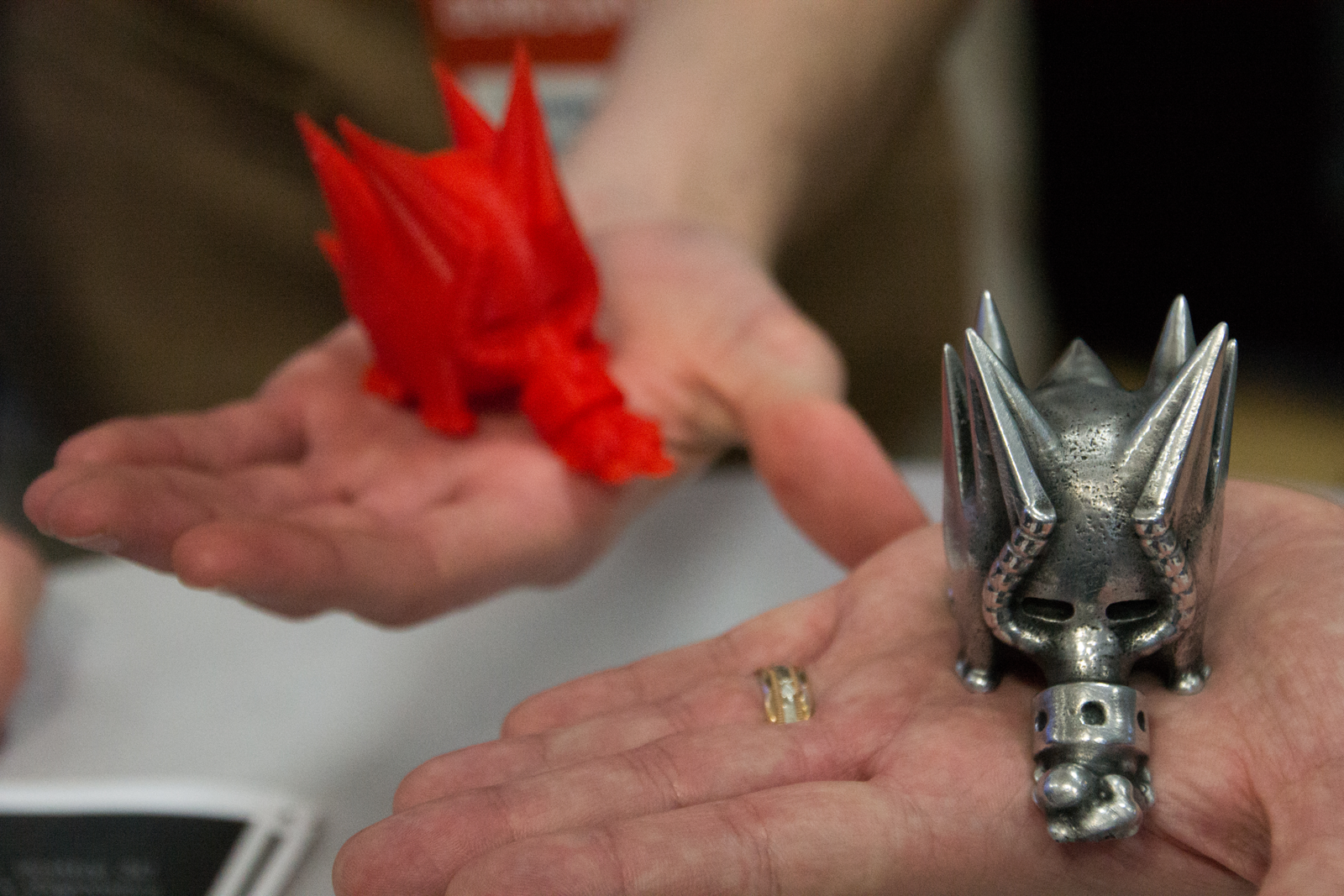

Demo Day this year saw, accompanying the pitch presentations, speeches by many of Chattanooga’s leaders, like city mayor Andy Berke and county mayor Jim Coppinger, as well as a keynote by leading 3D printing analyst Terry Wohlers and a panel discussion that included Stratasys’ Director of Marketing, Bruce Bradshaw, VP of Corporate Development & Ventures for 3D Systems, Hugh Evans, and Jim Underwood, Senior VP of Manufacturing & Operations at PlayCore. The group enlightened the audience with what they saw as the main reasons for investing in the technology. Though Underwood alluded to a future possibility of 3D printing custom slides for playgrounds, the discussion remained extremely grounded. Wohlers, for instance, pointed out how the jewelry industry is as big as the auto industry, but with fewer regulations. Bradshaw explained that the 3D printer manufacturers used to be the ones approaching CAD companies for business partnerships; now, though, the tables had turned. All agreed that engineers these days had to be one part designer and one part mathematician to fabricate 3D printed parts. Evans concluded the panel with some fun words of advice, saying to all of the new folks entering the 3D printing industry for the first time, “Welcome to the party!” And, as interesting as the panel was, the real show began when the 3D printing start-ups began making their pitches.

As strong as the teams were before they made it to Tennessee, it was the help of these experts that they were really able to start maturing into developed businesses. For instance, TrakTek3D didn’t begin as a business-to-business industrial 3D printing and design service provider. At the start, TrakTek3D was looking to 3D print horseshoes for racehorses. When I heard this, I thought it was genius. What racehorse owner wouldn’t want to lighten the load of their steeds with partially hollow, tailor-made horseshoes? While at GIGTANK, however, the company performed some market research to determine that 3D printing actually didn’t benefit the racing industry in any way: 3D printed shoes were no lighter, no cheaper, no faster to make, and at least 100x more expensive than the aluminum shoes already being manufactured by traditional means.

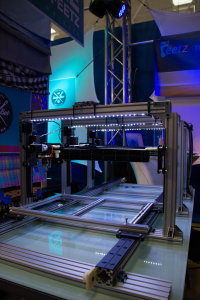

Lathon was another company that benefited from the accelerator. Originally, the desktop 3D printer manufacturer attempted a launch on Kickstarter, but had been unsuccessful in meeting their fundraising goal. Rather than give up, Lathon was able to convince eight of their backers to purchase their 3D printer as part of a pilot program. Though the large, dual extruder machine, capable of 70 micron resolution, seemed adequate for desktop fabbing, Lathon added an important and unique feature under the influence of GIGTANK.

founder Nohtal Partansky pitches at GIGTANK” width=”1600″ height=”1067″ />

founder Nohtal Partansky pitches at GIGTANK” width=”1600″ height=”1067″ />Not only did the accelerator push the team to polish their online aesthetic and overall brand, but Lathon was able to form a partnership with Verizon to include a novel wi-fi module on their 3D printer. What’s interesting about this piece of hardware is that it doesn’t just let users connect their printer to PrintToPeer’s cloud platform; it also allows Lathon to troubleshoot and diagnose problems with the machine remotely. Given the plethora of problems faced with desktop 3D printers – extruder jams, heated bed malfunctions, etc. – this makes Lathon one of the few 3D printer manufacturers capable of working through a customer’s problems virtually (the only other example of this I’m aware of is inDimension3).

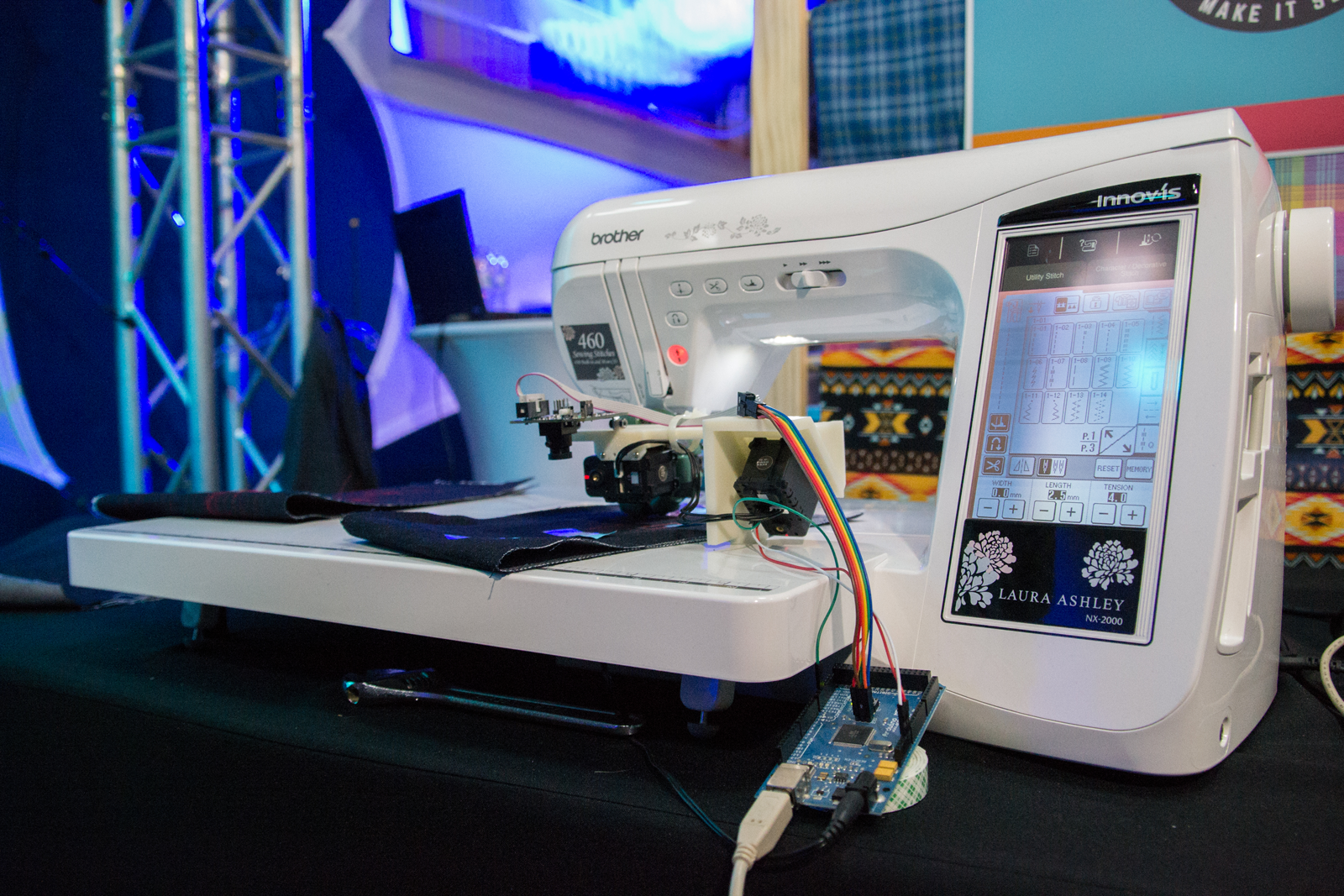

Like Lathon, the other teams were able to completely reshape their branding through GIGTANK. The night before the event, almost every company relaunched their websites, presenting new, sleek pages with simple, clear icons reminiscent of the most popular brands on the web. Seambot’s site is a great example, of this and their investor presentation concisely and elegantly outlined their product: A customer could visit their shop, scan their body, select and modify a piece of clothing, and Seambot would implement autonomous technology to cut and sew an outfit. CNC would be used to slice the cloth, while a proprietary sewing machine mechanism stitched the final piece. We even got to see the beginning stages of the Seambot prototype at the GIGTANK exhibition hall. Though not perfect, the team could be on the way to completing its prototype with enough funding.

One specific story that seems to underline the quality of the additive manufacturing experts provided to the teams is that of Feetz, the 3D printed shoe company that hit the scene earlier this year. Started by Lucy and Nigel Beard, Feetz looked primed for success even before heading to GIGTANK, but when Shapeways engineer and GIGTANK additive manufacturing expert, Graham Bredemeyer, joined the team, they really got onto their feet. Graham helped Feetz design a patent-pending 3D printing assembly line, an almost micro version of those seen at TNO and 3D Systems. With three print heads and a single build plate, Feetz shoes now pass under different extruders that print three different materials and/or colors, allowing their multimaterial shoes to be printed on a single device. Of course, they may have been able to pull of their business without Graham’s help, but possibly not as quickly or without developing their unique technology.

While working with the GIGTANK teams, Graham earned the reputation, from one other 3DP mentor, of being a “3D printing genius”. And, when we met him out at dinner with Terry Wohlers, it seemed like the title might suit him. Discussing the technology with Wohlers, listed as the most influential person in 3D printing by TCT Magazine in 2007, Graham was really able to hold his own. The two of them hashed out ideas for the future of 3D printing, describing machines years down the line that could 3D print a metal object and then polish it cleanly with lasers all in one machine.

In addition to the help of the 3D printing genius, Feetz gained a good deal of traction from the city itself. Lucy told me that she was able to pitch her idea to investors in the area much more successfully than she had been able to in Silicon Valley. In fact, she loved the city so much, she’s shifting her entire operation to Chattanooga. And it’s hard not to see why. The city is flushed with resources and opportunities for companies seeking to establish themselves there.

Industry at GIGTANK” width=”1600″ height=”1067″ />

Industry at GIGTANK” width=”1600″ height=”1067″ />With Blue Cross Blue Shield and the local hospitals in Chattanooga, it was natural that we’d see some 3D printing-health sector crossover start-ups. Nestegg Bio is one that wants to make new drug discovery a simpler and more affordable process with a product called RootCube. Unlike Organovo, which is creating cellular assays of 3D printed liver tissue for testing new medicines, Nestegg wants to 3D print vascular canals around which researchers can seed whatever organ tissue they want to study.

For example, if Pfizer wants to study the effects of a medicine on kidney cells, Nestegg will 3D print, into a small container, the vascular network found in a portion of a kidney using a sugary, dissoluble material. This container, the RootCube, is then shipped to Pfizer, who seeds the 3D printed sugary cells with kidney tissue. In the process, the sugar structure dissolves, leaving a series of canals that the researchers can pump blood into to maintain the cells’ viability. Unfortunately, the company has yet to prove their concept entirely and are currently looking for funding to test the tissue seeding process. So, it’s still unclear whether or not any tissue will grow around their printed structures.

While all of the 3D printing teams had the potential to take advantage of Chattanooga’s gigabit network, the 3D printing start-up to do so most obviously was 3DOps. One of the most obvious advantages of the Gig is that it allows for lightning fast uploads and downloads, with very little latency. For consumers, this means great Netflix streaming, but for businesses like 3DOps, the Gig is perfect for sending and receiving large amounts of data.

What 3DOps proposes to do is provide to 3D models for surgeons on which to practice surgical procedures. As we’ve covered previously on 3DPI, doctors have only 2D scans and virtual models to help them prepare for an operation. An increasing number of surgeons, however, are having CT scans of their patients’ problem areas converted to 3D printed models so that they can see and feel where they will be operating, even going so far as to rehearse a surgery on the model. 3D printed models, it’s been suggested, can ultimately reduce surgery time and mistakes made in operations.

Uploading, converting, and sending CT scans, in most places, requires a huge amount of computing power. Things are different in Chattanooga, where the net is fast and the grid is smart. Due to the Gig’s fast as light speed, 3DOps can quickly download a series of CT scans, convert them into 3D printable models, and send them back over to the hospital in a fraction of the time. The company plans to lease Connex3 3D printers out to each hospital in its upcoming pilot program, allowing surgeons to 3D print their models on site. And, because they’ll use Connex3 machines, doctors may be able to fabricate their models in soft and hard materials and multiple colors to more accurately represent the tissues on which they’re operating. Incidentally, researchers who studied the use of 3D printed models to improve surgical procedures indicated a desire for materials that are more similar to organic tissue. 3DOps’ Daniel Hampton has contacted the authors of the study, with no word back, as of yet.

3DOps is just one of many examples of how new companies in Chattanooga are utilizing the Gig to improve business and the quality of life. And, even if the city has been revitalizing itself since the 70s, the Gig has brought a whole new vitality to the area. And, the way that people talk about it, it’s almost as if the Gig is some sort of benevolent creature. “The Gig brings opportunity.” “The Gig is making people want to move their business from Silicon Valley to Chattanooga.” “What will it be like if the Gig comes to Nashville?” All hail, the Gig! For it brings riches!

In actuality, as you’ll gather from part two of this report, it’s not that this benevolent creature sprang up from the depths of the Tennessee River. The Gig is human made, the result of the unique, close-knit, seemingly magical community that makes up the city of Chattanooga. The town is so magical, in fact, that Danielle and I wondered aloud throughout our trip, looking at the city’s newly redesigned river front, expansive walking bridge, and lush parks, “What’s the catch?”

There must be some werewolf that haunts the city’s streets during a full moon. Or maybe Chattanooga is actually made up of a bunch of ghosts. Or maybe the city dons black velvet cloaks at night and feeds stray cats to the Gig, chanting, “Feed the Gig! Feed the Gig!”, in order to give it power. Or maybe it’s just a city that’s experiencing a perfect storm of elements – a fast Internet, a warm and smart community, a low cost of living, and a host of other things – priming it to be something more than the Silicon Valley of the Southeast. And, if that’s the case and we can find a nice place to live – houses are so affordable there! – then maybe Danielle and I will move to Chattanooga. And maybe you will, too.

For more photos from the GIGTANK Demo Day 2014, browse below. All photos pictured in this article by Danielle Matich of Volim Photography.

[nggallery id=178 template]

Leave A Comment