In the latest edition of the Industry news digest – Sliced, we have news about 3D printed spare parts, future of additive manufacturing in India, and 3D printed food. Read on to learn more about Sintratec, Mimaki, 3D Systems and Renishaw.

Beyond borders

Sintratec, a Swiss SLS printer manufacturer, has signed a distribution contract with CMF Marelli, an Italian reseller of metrology machines and 3D printers. CMF Marelli will sell Sintratec 2 SLS 3D printer and PA12 and TPE materials.

Sintratec’s Gabor Koppanyi, Head of Marketing and Sales, “With nearly two decades of experience in the operation and service of 3D printing systems, we have found our perfect industrial partner in Italy […] CMF Marelli is actively supporting its customers in the implementation of new production methods.”

HARZ Labs, a Russia-based 3D printing materials manufacturer, has chosen the Italian distributor of resin 3D printers, Lumi Industries, as resellers of its dental materials in Europe.

VBN Components, a Swedish materials manufacturer, has signed a licensing agreement with an engineering group. Martin Nilsson, CEO of VBN Components, said, “After considerable technical testing and analysis, the agreement has been signed and we are very much looking forward to collaborating with this global partner.”

“The license agreement shows that our initial idea of making better materials with 3D printing, rather than what’s possible traditionally, is really working.”

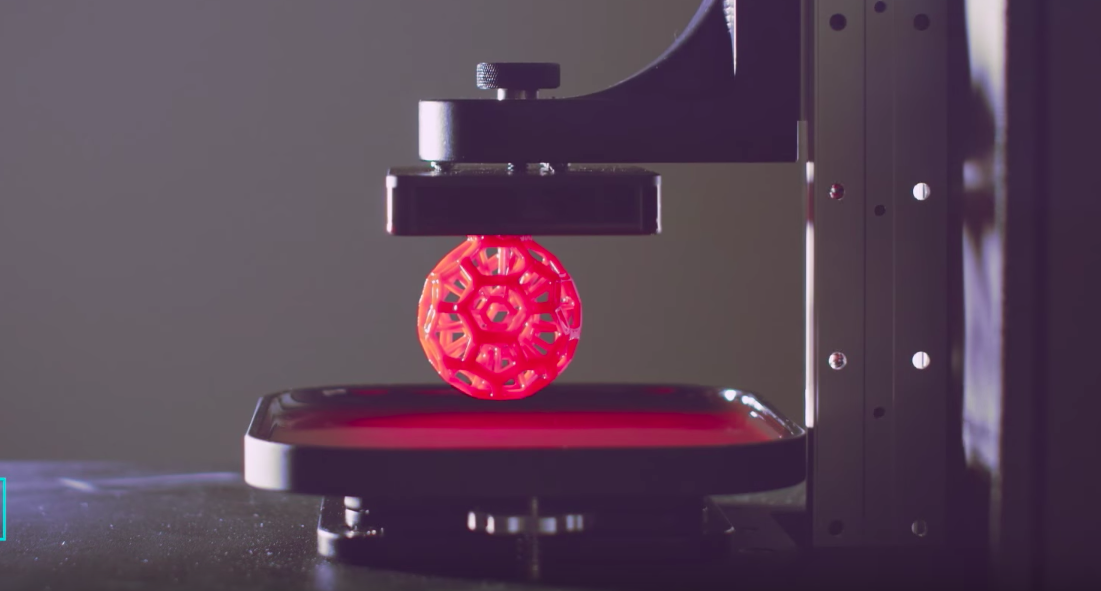

ZVerse and Carbon, a California-based pioneer of CLIP technology, have formed a strategic alliance.

ZVerse CEO, John Carrington, said, “We are thrilled to partner with Carbon to deliver their Production Partners and Customers the easiest path from idea to manufacturable files. Our mission is to increase the pipeline of production applications for our digital manufacturing partners, at scale, by removing the friction associated with providing design services.”

HP India has signed a Memorandum of Understanding (MoU) with the Andhra Pradesh Innovation Society (APIS) and Andhra Pradesh Economic Development Board (APEDB) to build a Centre of Excellence (CoE) for 3D printing. The state of Andhra Pradesh is also home to the $6 million AP MedTech Zone, which includes 3D printing facilities.

Managing Director of HP India, Sumeer Chandra, said, “We believe HP’s cutting-edge 3D printing technology will fuel innovation in manufacturing and help upskill young professionals to make them ready for Industry 4.0 in the state.”

Mimaki USA has opened a Technology Center in Los Angeles California. The 28,446-square-foot large facility houses Mimaki’s whole product portfolio, including graphics, textiles and 3D printers. Mimaki USA President Naoya Kawagoshi, said, “Our new center will make it easier for existing and prospective customers in the region to see our full portfolio of innovative printing solutions in action.”

PADTC, a Tempe-based simulation, and 3D printing products and services provider, has founded a spin-off company Oryx Additive. PADTC’s support removal machine, the SCA-1200HT, will now be available from Oryx Additive.

The University of Technology Sydney has opened ProtoSpace, a maker space, and center for additive manufacturing research. ProtoSpace will be headed by Hervé Harvard, who said, “With some of the most advanced printers in the world, linked with academic expertise in using and extending 3D printing technology, ProtoSpace is delivering a unique resource to help achieve innovative Australian ideas.”

HAVA3D Group, a French additive manufacturing specialist, is now the sole distributor of the customized filaments made by Kimya. The filaments will be distributed through HAVA3D’s subsidiary SOTEC3D.

Vincent Albert, President of HAVA3D, said, “We were immediately convinced by the quality and performance of the Kimya products and the diversity of the range. We are delighted to announce today that the Kimya filaments will be available via SOTEC3D and our other resale distributers.”

At the upcoming International Dental Show 2019 (12 March – 16 March) in Cologne, 3D Systems will showcase its range of dental solutions, which includes the award-winning NextDent 5100. Rik Jacobs, vice president, general manager, dental, 3D Systems explained, “It is very rewarding to see the industry embrace the NextDent 5100, and to be joined by clinicians and key opinion leaders who want to share the stories of their successes here at IDS 2019.”

“From denturists to highly-regarded educators, everyone is experiencing the transformational power of this solution.”

The U.S. State House of Representative has passed a law banning 3D printing of guns. The legislation was pushed by State Attorney General Bob Ferguson, who said, “I support the Second Amendment. With that said, we cannot allow felons and other dangerous individuals to make an end-run around our state’s background check requirements by printing untraceable, undetectable 3D-printed guns […] Guns that can evade metal detectors pose too great a risk to the safety of our communities.”

Future of spares

Netherland-based CNH Industrial N.V., one of the largest capital goods manufacturers, has 3D printed its first spare parts. These parts are for buses and agricultural equipment. Furthermore, in the future, CNH will also investigate the production of metal components using 3D printing.

Adding beauty with 3D printing

Swedish care homes will be using 3D printed food in their facilities. Richard Asplund who is the head of the catering department at Halmstad municipality, explained, “When you find it hard to chew and swallow, the food that exists today doesn’t look very appetizing.”

“So the idea is to make something more aesthetic to look at, to make it look good to eat by recreating the original form of the food.”

The project is facilitated by researchers at the University of Kristianstad and Lund University and also includes 3D printing companies like Addema and Cellink.

Healing bones

Clark Bullet and Kevin Gesmann, senior engineering students at Duke University, used 3D printing to treat the broken collarbone of their fellow student and football quarterback Daniel Jones.

3D printed assistance

Renishaw, a metal 3D printer manufacturer based in the UK, has collaborated with Irish Manufacturing Research (IMR) and nTopology, a 3D software maker, to demonstrate 3D printing of spinal implants using Renishaw machines. Renishaw’s RenAM 500M metal system.

Sean McConnell, Senior Research Engineer at IMR, said, “Renishaw worked tirelessly with us on improving the AM process for producing the spinal implants. Together, we designed a set of experiments that yield the most appropriate parameter settings for the product. As a result, we reduced the amount of post-processing required on key features of the implants by a factor of ten.”

Furthermore, in the dental industry, Renishaw has also shown how it integrates Polygonica, a mesh manipulation software, to streamline its digital manufacturing workflow.

PrintLab, a developer of 3D printing lesson plans based in England, has released a lesson plan which trains students to design and 3D print assistive technologies. The plan was developed with the help of Makers Making Change, a social network which connects makers with people who require assistive technologies.

To learn more about 3D printing subscribe to our 3D printing newsletter. For more information join us on Twitter and Facebook.

Also we have plenty of jobs in the industry, visit our Jobs page.

Featured image shows Sliced logo over the Renishaw sponsored Bloodhound Super Sonic Car. Original photo via Autoexpress.

Leave A Comment