In this edition of our 3D printing news digest, Sliced, we have news about the restoration of 911 Porsche and a parish church using 3D printing, U.S Navy blueprint digitization, and scan-to-CAD software.

We start today’s digest with a date for your diary. The European Society for Precision Engineering and Nanotechnology (euspen), is co-hosting a Special Interest Group (SIG) with American Society of Precision Engineering (ASPE) on 16-18 September in Ecole Centrale de Nantes, France. The meeting will address the barriers to the adoption of 3D printing and future opportunities in the industry.

Read on to learn more about FIT, Shining 3D, General Dynamics, Advanced Manufacturing Research Center at the University of Sheffield, DuPont and more.

Merging the past and the future

ABCar Oldtimers, a Polish car restoration company is using Zortrax 3D printers to restore a 1969 Porsche 911, which the company says was driven by Polish rally driver Sobiesław Zasada.

Bartłomiej Błaszczak, Design & Engineering Director at ABCar Oldtimers, said, “3D printing is incredibly helpful. It speeds up work and limits costs linked to prototyping individual parts. Compared to mold milling, it reduces costs by an order of magnitude.”

Błaszczak continued, “This is our latest project working with Zortrax printers. We use the M300 Plus and M200 models when prototyping molds and creating missing parts, such as bushings or gaskets.”

St. Laurentius, a small parish church in Altmühldorf, Upper Bavaria, recruited the German 3D printing specialist FIT Additive Manufacturing Group for restoration work.

With the help of artist duo EMPFANGSHALLE and architect Oliver Tessin, the 8 m high and 2.5 m wide artwork was finished using PA12 on an SLS 3D printer.

From physical to digital

Shining 3D, a Chinese hardware manufacturer, in collaboration with one of the largest 3D printer manufacturers, 3D Systems, has released Geomagic Essentials, a 3D scan-to-CAD software. The software is released as a bundle with Shining 3D’s the Einscan Pro 2X scanner series.

The U.S. Navy is digitizing the blueprints of its USS George Washington aircraft carrier. With the renovation of one of the largest aircraft carrier underway, the use of digital technologies is not surprising. Chris Miner, vice president of Navy programs, said, “The new shipbuilders coming in, they’re not looking for you to hand them a 30-page or a 200-page drawing […] We’re really transitioning how we train folks and how we do things as far as getting them proficient.”

Increasing materials range

AMRC Castings, a subsidiary of the Advanced Manufacturing Research Center (AMRC) at the University of Sheffield has enhanced the process of 3D printing sand molds. The research body possesses the ExOne S15 and the ExOne SMax 3D printer by Pennsylvania-based ExOne which are used to produce sand cores and molds in silica for aluminum and iron casting. The Casting group fitted the ExOne S15 3D printer with an advanced operating system which increases the speed of the machine. The ExOne S15 can now also print artificial sand called Cerabead. In addition to this, the ExOne SMax was fitted with a larger build envelope of 1,800 x 1,000 x 700mm.

Anthony Kenney, Commercial Lead at AMRC Castings said, “due to further investment in process enhancements we have been able to increase capacity, accuracy and further reduce lead times.”

Tessenderlo Group, a Belgian chemical company, has released the ClaroBGI600, a material made of gelatin that can be used in bio-inks to improve printing speed and prevents nozzle clogging.

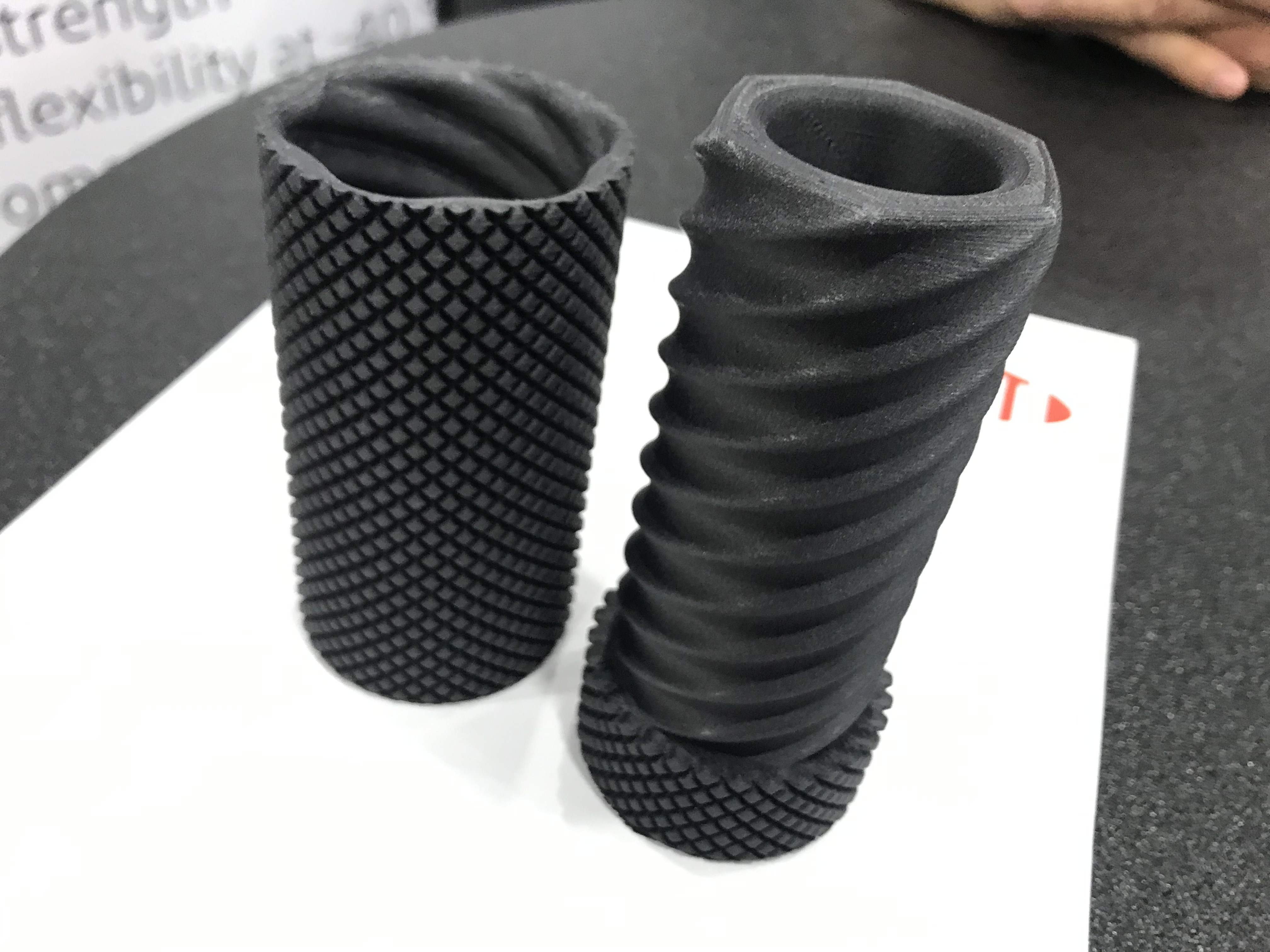

At this year’s RAPID + TCT, US-based chemicals manufacturer, DuPont introduced 3D printing materials. The company has added six more polyamide pellet products in its Zytel and Hytrel range, including elastomer TPC-ET pellets. New products also include filaments in the Hytrel series.

Christophe Paulo, DuPont’s strategic marketer, EMEA, said, “As 3D printing capabilities advance beyond traditional prototyping and small-volume production, the industry is looking to scale up and accelerate production while driving down costs […] By delivering our products as pellets as well as filaments, DuPont gives customers the flexibility to use the same material across different processes.”

Digitizing manufacturing

NTUitive, an innovation company of the Nanyang Technological University, Singapore (NTU Singapore), has set up a 3D printing service startup called Secur3DP+. The startup was established in collaboration with ISF Incubator a startup wing of Intellectual Ventures (U.S). Powered by blockchain, the Secur3DP+ will provide digital solutions to 3D printing companies to secure IP and ensure quality assurance.

Eng Kiat Low, CEO of Secur3DP+, “Our company is filling a critical gap in the mass adoption of 3D printing […] By creating a global ecosystem of trusted partners, we hope to accelerate the adoption of 3D printing and allow businesses all over the world to get the products they need and do so securely, anytime, anywhere.”

General Dynamics, a Virginia-headquartered global aerospace and defense company, has signed a contract with GE Additive according to which the GE Additive Print Services will help the aerospace company qualify 3D printed parts.

Jason Deters, a specialist in Process & Technology Development at General Dynamics, said, “General Dynamics is always looking for innovative technologies to enhance our products, and additive manufacturing holds real promise in the near term. We’ll continue teaming with leading suppliers such as GE Additive as we uncover additional applications for this exciting technology.”

Making ideas into reality

Design Reality, a UK-based design consultancy firm has installed an HP Jet Fusion 4200 3D printer. By doing this the service bureau of the company located in Wales is now capable of taking ideas from design to prototyping to production.

SCANLAB, a German manufacturer of laser beam and positioning systems, has introduced a new product in the excelliSCAN line. The excelliSCAN 20 scan system uses an RTC6 PCI Express control board and has a 14 mm aperture for improved accuracy. The excelliSCAN 20 can be used in micromachining and 3D printing.

CEO of SCANLAB, Georg Hofner, said, “With the excelliSCAN 20, we’re serving demand from customers who want to break through their previous processing limitations. Initial application tests have been very promising.”

A survey by Manufacturing Technologies Association and London-based Close Brothers Asset Finance has found that many engineering and manufacturing firms in the UK are not looking to take advantage of the recent increase in Annual Investment Allowance (AIA). The AIA is a tax relief that allows British businesses to deduct the total amount of qualifying expenditure capital between £200,000 and £1 million for a given year.

Vote now for 2019 Industry Awards.

For the latest news about additive manufacturing, subscribe to our 3D printing newsletter and join us on Facebook and Twitter. We also have jobs in the industry, visit our Jobs page to learn more.

Featured image shows a 1969 Porsche 911 with Sliced logo. Image via Robb Report.

Leave A Comment