The month of September met a variety of additive manufacturing shows such as IMTS, TCT, as well as New Scientist Live. The 3D printing industry also saw many technological advancements aiming to accelerate industrial metal additive manufacturing.

This includes EOS’s M300 series of direct metal laser sintering (DMLS) 3D printers and 3D Systems and GF Machining Solutions’, DMP Factory 500.

IMTS and the industrialization of 3D printing

Industry returned to Chicago for the 2018 edition of IMTS. There, additive experts, such as Bertrand Humel van der Lee, the Chief Customer Operations Officer (CCOO) at EOS, discussed the increasing interest in industrial 3D printing.

“There was almost immediate commercial interest in our EOS M 300 system, which we launched at the show. Overall, as production moves to more customized, shorter-term product cycles, the manufacturers we’re working with are finding immediate value in bringing in more machines.”

Also at IMTS, 3D Systems and GF Machining Solutions, unveiled the DMP Factory 500, an industrial, automated metal 3D printing system for high-quality, large part production.

In other news, with the aim of creating a complete production cell for additive manufacturing aluminum components, the NextGenAM project established its first pilot plant in Varel, Northern Germany.

In addition, metal additive manufacturing materials producer Metalysis entered into industrial-scale production of its metal powders. As a result, the company’s plant is capable of producing in the region of 10,000 – 100,000 kg+ (10s to 100s of tonnes) of metal powders.

Similarly, Aurora Labs, a metal 3D printer manufacturer based in Australia, positioned itself at the forefront of metal 3D printing technology, with the ongoing development of its latest system, the large-format Alpha 3D printer.

Birmingham’s TCT SHOW

Industry also returned to the TCT Show in Birmingham this September. The show displayed a number of desktop 3D printers for high-quality FFF additive manufacturing as well as multi-material 3D micro-fabrication. This included Swiss 3D TEC, DM3 printer, Raise3D’s Pro2 series of 3D printers, and BMF Material Technology’s the nanoArch S140 PμLSE 3D printer.

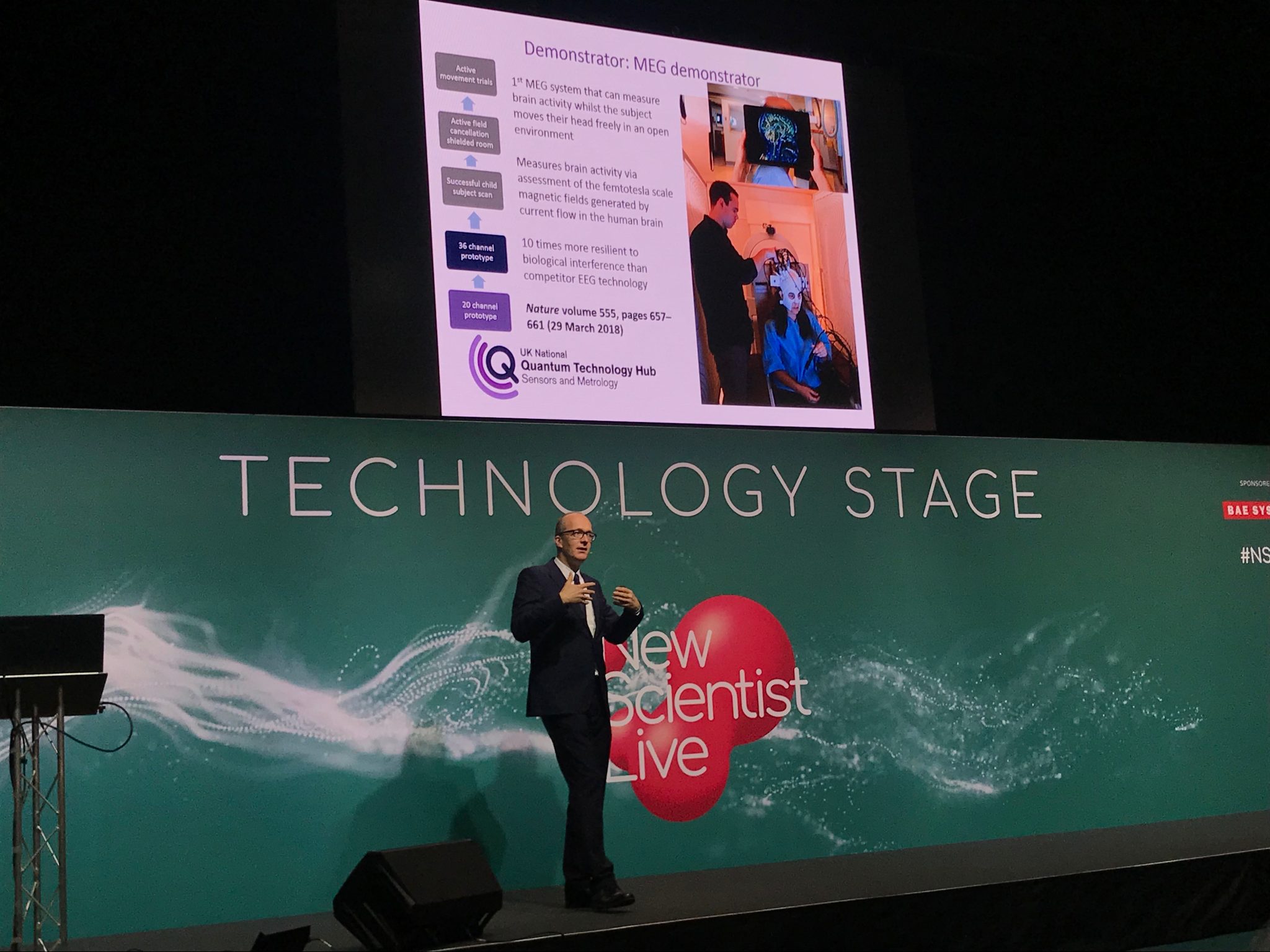

New Scientist Live

Observing the medical applications of additive manufacturing, Industry attended New Scientist Live (NSL) 2018 in London. At the event, Professor Leroy “Lee” Cronin, the Regius Chair of Chemistry at the University of Glasgow, described how his team is using 3D printed parts for chemical computers.

“The 3D printed parts are used as the containers for chemical reactions and act as holders to make the cellular array. These help us to reconfigure different shapes.”

A 3D printing curriculum

In education, PrintLab, a UK based 3D printing reseller, announced the launch of additional language options for its PrintLab Classroom learning program. The first new language are now available in Polish, Spanish and Chinese. The Polish version was done in collaboration with Polish 3D Technology & Education supplier, Paxer.

Moreover, the Australian government, in partnership with 3D printing bureau and reseller, Objective 3D, announced $2 million (AUD) in funding for a new additive manufacturing (AM) virtual hub.

What 3D printing companies and stakeholders deserve a Industry Award? Make your nominations now for 2019.

For the latest Industry news subscribe to our newsletter (it’s free!), follow us on Twitter and like us on Facebook.

Looking for a fresh start in the new year? Visit Jobs to get a head start.

Featured image shows the exterior of IMTS 2018. Photo by Michael Petch.

Leave A Comment