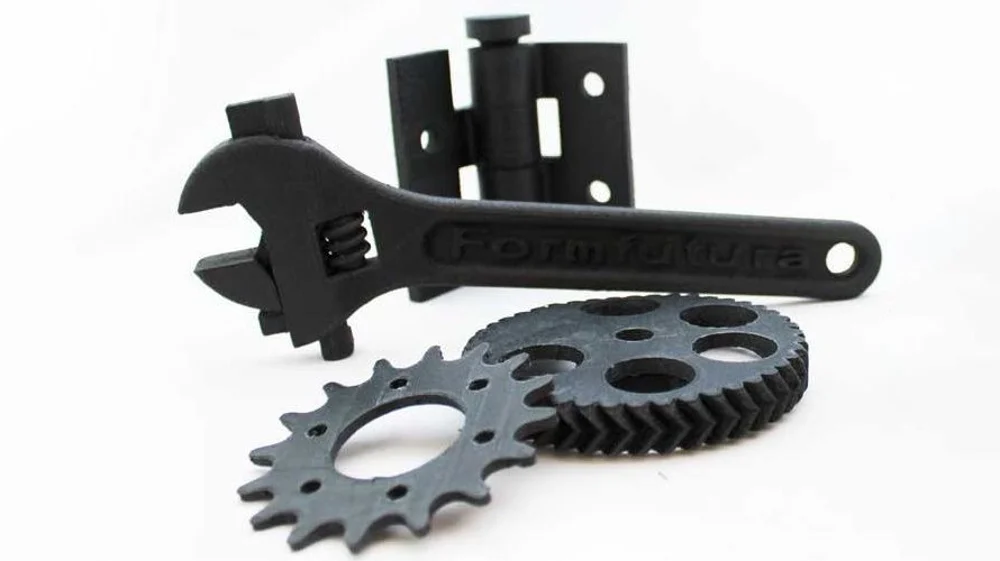

Carbon fiber filament is a tough material with a nice matte finish. Check out our guide to the best carbon fiber filaments on the market!

Carbon fiber filaments are composite materials formed by infusing fragments of carbon fiber in a polymer base, similar to metal-infused filaments but with tiny fibers instead. The polymer base can be of different 3D printing materials, such as PLA, ABS, PETG, or nylon, among others.

While true carbon fiber materials have long continuous fiber strands that improve mechanical resistance, these filaments contain short particles of around 0.01 mm in diameter. Although this is enough for improving the strength of printed parts, keep in mind that such filaments cannot compare to the actual material.

Why This Composite?

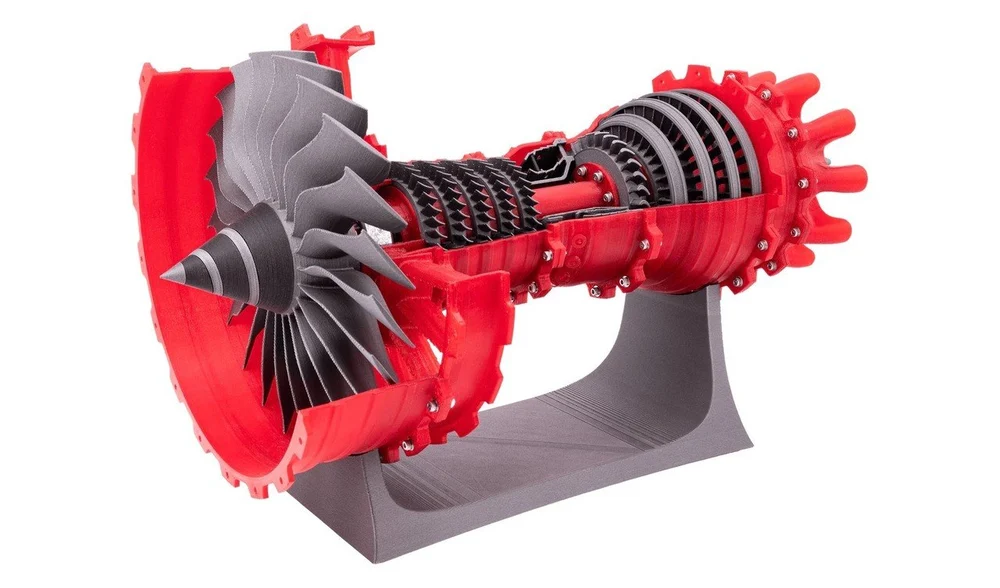

For those seeking tougher 3D printing materials, carbon fiber filament presents a relatively easy alternative to the more expensive and demanding materials, such as polycarbonate (PC) or PEEK. Moreover, the increased strength provided by the carbon fiber particles contributes to greater dimensional stability, helping to avoid warping and shrinking.

3D printing these materials, however, does present some issues. The infused carbon fiber particles aren’t melted by the nozzle during extrusion, which may lead to frequent clogging. In addition, these particles work as abrasive agents during extrusion, which over time will wear down a brass nozzles’ internal bore. This is why special nozzles like hardened steel are strongly suggested for printing with composite materials.

PROS

- Increased strength and stiffness

- Good dimensional stability

- Overall nice surface finish

- Lightweight

CONS

- Frequent clogging

- Abrasive filament that wears down brass nozzles (requires special hardware)

- Polymer/carbon fiber mixture increases the material’s brittleness

Note that in this list we’ve focused on filaments that can be printed on a consumer 3D printer. There are higher-end carbon-fiber materials, like those from Markforged and Roboze, but these require specially designed 3D printers.

So, now that we know what we’re dealing with, let’s look at the best brands!

Protopasta

Protopasta’s carbon fiber PLA is perhaps one of the easiest materials on this list to print due to its PLA polymer base. According to the company, it offers great layer adhesion, low warpage, and a nice matte finish. The bulk material contains 15% (by weight) chopped carbon fibers, making it more brittle than standard PLA.

The increased rigidity provided by the carbon fiber reinforcement is ideal for parts that are not supposed to bend, such as frames and supports. Protopasta recommends using a 0.5-mm nozzle or bigger to avoid excessive clogging and also warns users about the abrasive nature of this filament.

- Diameters: 1.75 mm, 2.85 mm

- Density: ~1.3 g/cm3

- Bed temperature: 50 °C (not required)

- Hot end temperature: 200-230 °C

- Price: ~$30 for 500 g (~$60/kg)

MatterHackers

MatterHackers’ NylonX filament is composed of a nylon base with 20% (by weight) micro-carbon fibers. It combines the durability of nylon and the stiffness of the chopped carbon fibers to create a tough, shatter-resistant material ideal for producing functional parts.

While nylon is known for being a difficult material to 3D print, the infused carbon fibers in the filament provide enough dimensional stability to reduce warping significantly. However, we did still experience some warping and stringing when we reviewed this filament.

Nylon is very moisture-sensitive, so this filament must be kept dry and packaged with a desiccator. Moreover, MatterHackers recommends using hardened nozzles like the Olsson Ruby.

- Diameters: 1.75 mm, 2.85 mm

- Density: ~1.0 g/cm3

- Bed temperature: 60-65 °C (with PVA glue stick)

- Hot end temperature: 250-260 °C

- Price: ~$60 for 500 g (~$120/kg)

3DXTech

3DXTech is an American filament manufacturer that offers a wide range of carbon fiber-reinforced materials. Its CarbonX product line includes composites of PLA, PETG, ABS, polypropylene (PP), polycarbonate (PC), different types of nylon (PA6 and PA12), and even higher-grade plastics such as PEI, PEEK, and PEKK.

The carbon fiber-reinforced ABS is made from premium Sabic MG-94 ABS with 15% high-modulus carbon fiber. According to 3DXTech, besides increased stiffness, this filament also offers higher chemical resistance, dimensional stability, and ease of printing.

The manufacturer recommends using hardened nozzles with a minimum bore diameter of 0.4 mm. 3DXTech also recommends using layer heights of at least 0.25 mm, as smaller values may induce back pressures and result in jams and poor extruding performance.

- Diameters: 1.75 mm, 2.85 mm

- Density: Not specified

- Bed temperature: 100-110 °C (with Kapton tape or ABS/acetone slurry)

- Hot end temperature: 220-240 °C

- Price: ~$60 for 750 g (~$80/kg)

ColorFabb

ColorFabb’s XT-CF20 is a combination of their proprietary PETG Amphora 3D polymer with up to 20% carbon fibers. This polymer is free from styrene (a compound known to be harmful to our health and to smell terrible) and by itself, already offers the user enhanced mechanical properties like high toughness.

The manufacturer claims that XT-CF20 has great dimensional stability and heat resistance, being ideal for drone parts and automotive prototyping. Active cooling is recommended (at 50 to 90% power) and once the print is finished, it’s advised to let the build plate cool down to room temperature before attempting to remove the part.

- Diameters: 1.75 mm, 2.85 mm

- Density: ~1.27 g/cm3

- Bed temperature: 60-70 °C

- Hot end temperature: 240-260 °C

- Price: ~$60 for 750 g (~$80/kg)

eSun

eSun’s huge product portfolio wouldn’t be complete without carbon-fiber-reinforced materials. The so-called ePA-CF is a nylon-based filament with 20% carbon fiber by weight. The Chinese manufacturer is known for offering relatively cheap materials with superb quality, and the ePA-CF is no different, as many positive customer reviews confirm.

In addition to increased stiffness and wear resistance, this filament is claimed to be flame-retardant (UL94-V2), making it especially useful for applications that will be exposed to higher temperatures. As with other carbon fiber-reinforced filaments, eSun recommends using hardened nozzles with this material.

- Diameters: 1.75 mm, 2.85 mm

- Density: ~1.20 g/cm3

- Bed temperature: 80 °C

- Hot end temperature: 240-260 °C

- Price: ~$45 for 500 g (~$90/kg)

Source: https://all3dp.com/2/carbon-fiber-filament-explained-and-compared/